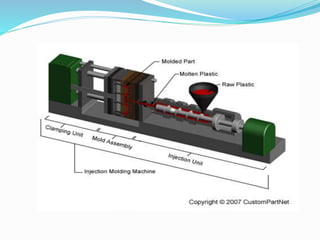

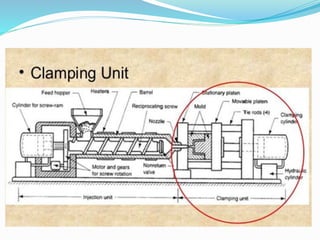

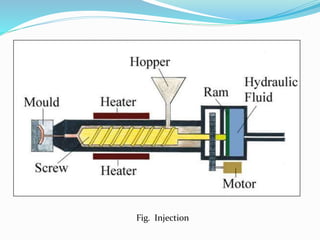

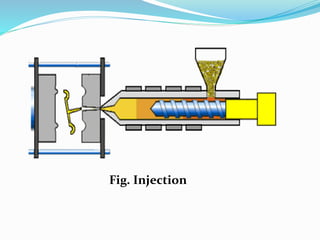

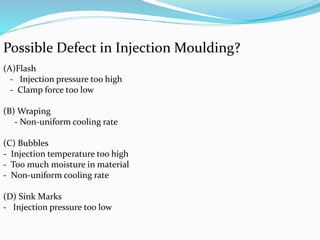

Injection molding is a widely used manufacturing process for producing plastic parts by melting raw plastic and injecting it into a mold. The process consists of four main stages: clamping, injection, cooling, and ejection, with potential defects like flash, warping, and bubbles. It is utilized in various applications, including consumer electronics, medical devices, and household items.