Embed presentation

Download to read offline

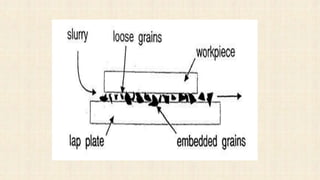

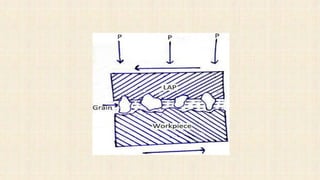

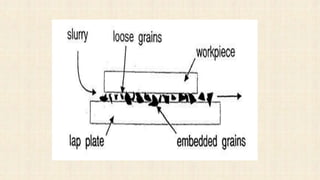

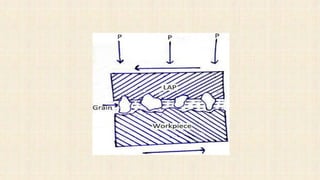

Lapping is a surface finishing process that uses loose abrasive powders at low speeds to achieve very tight tolerances of flatness, parallelism, thickness, or finish. It involves mixing abrasive particles with a liquid to form a slurry, placing the slurry on a rotating lap plate, and placing the workpiece against the slurry-coated plate so the abrasive grains can modify the workpiece surface through rolling/sliding contact. A lapped surface exhibits a dull, non-reflective appearance with multi-directional texture, especially for hard materials with surface roughness under 5 micro-inches.