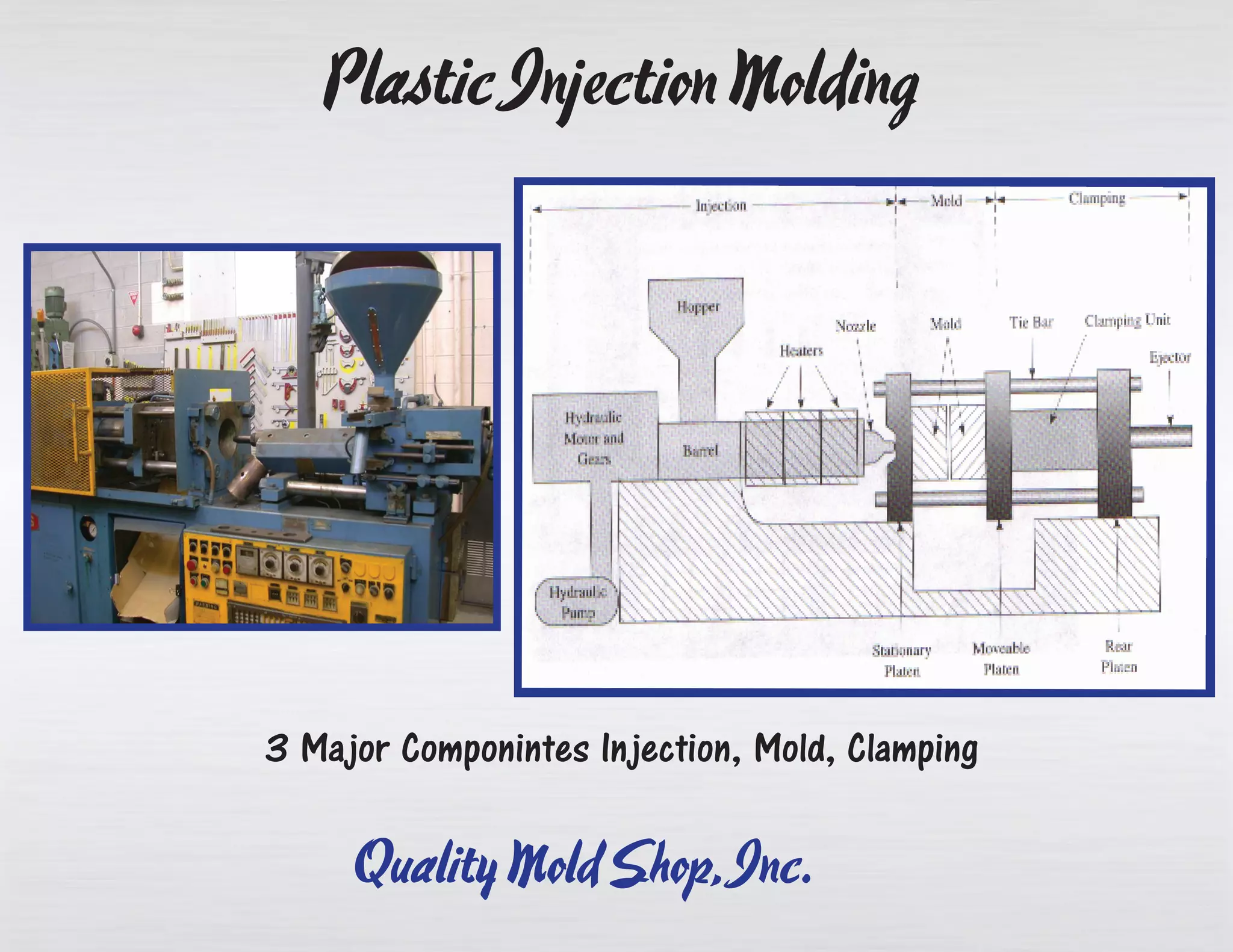

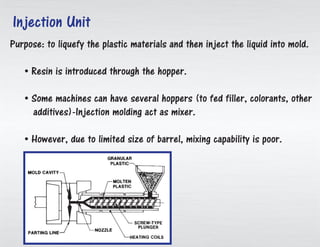

Quality Mold Shop, Inc. specializes in plastic injection molding, a process that creates discrete parts from thermoplastic and thermoset materials by injecting molten plastic into a metal mold. The document details the injection molding process, including the components involved such as the injection unit and clamping unit, as well as the importance of resin types in manufacturing various products. Injection molding is highlighted as a versatile method with applications across industries, including automotive, electronics, and medical products.