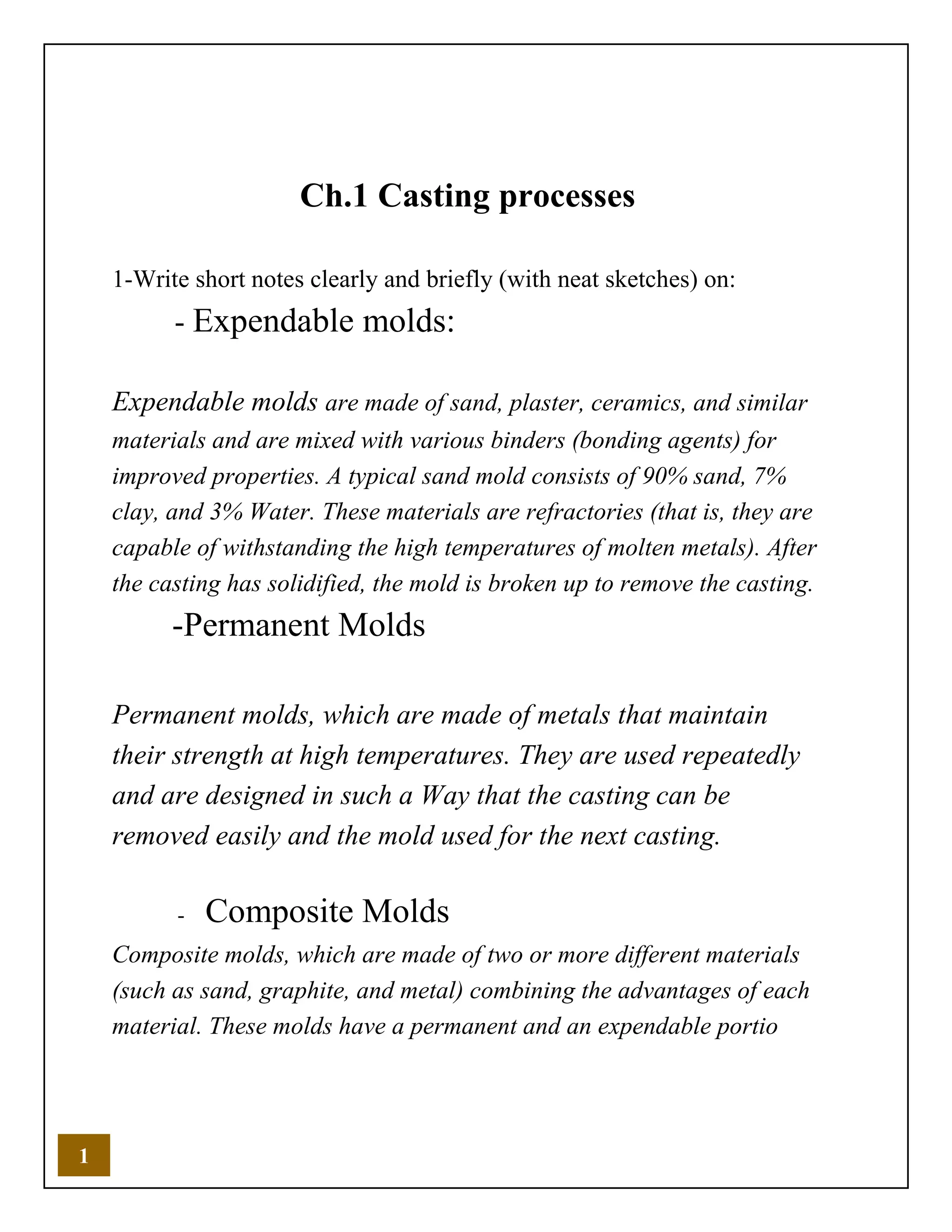

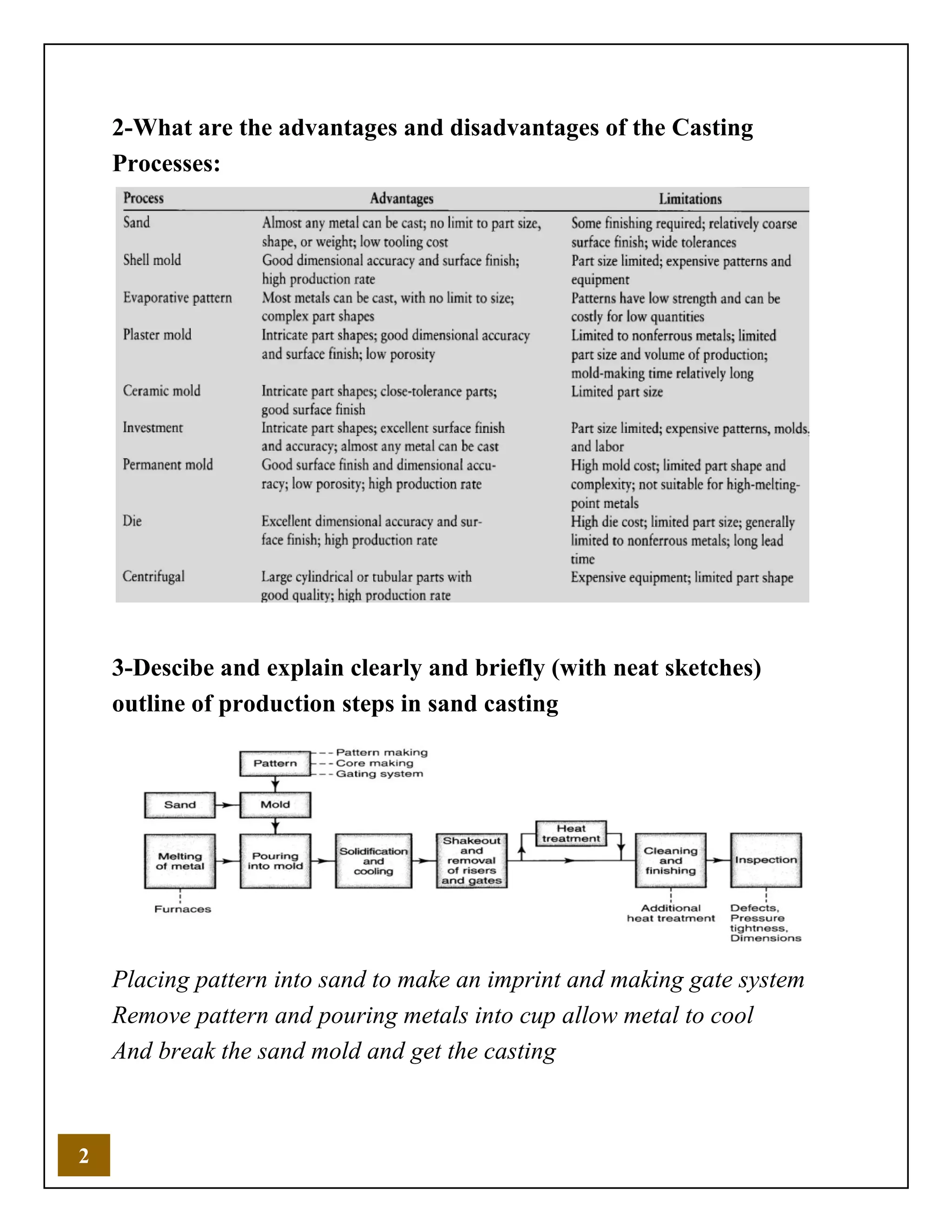

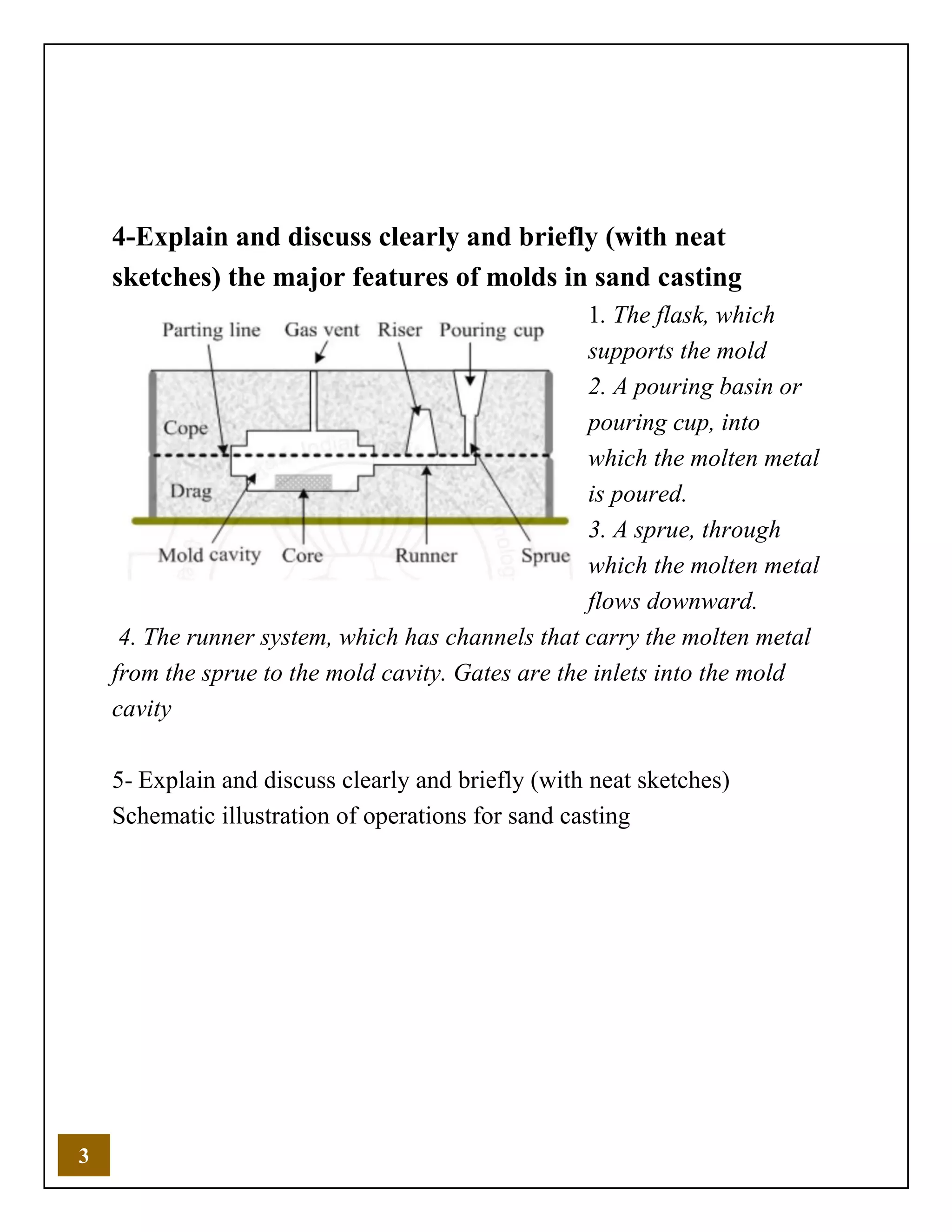

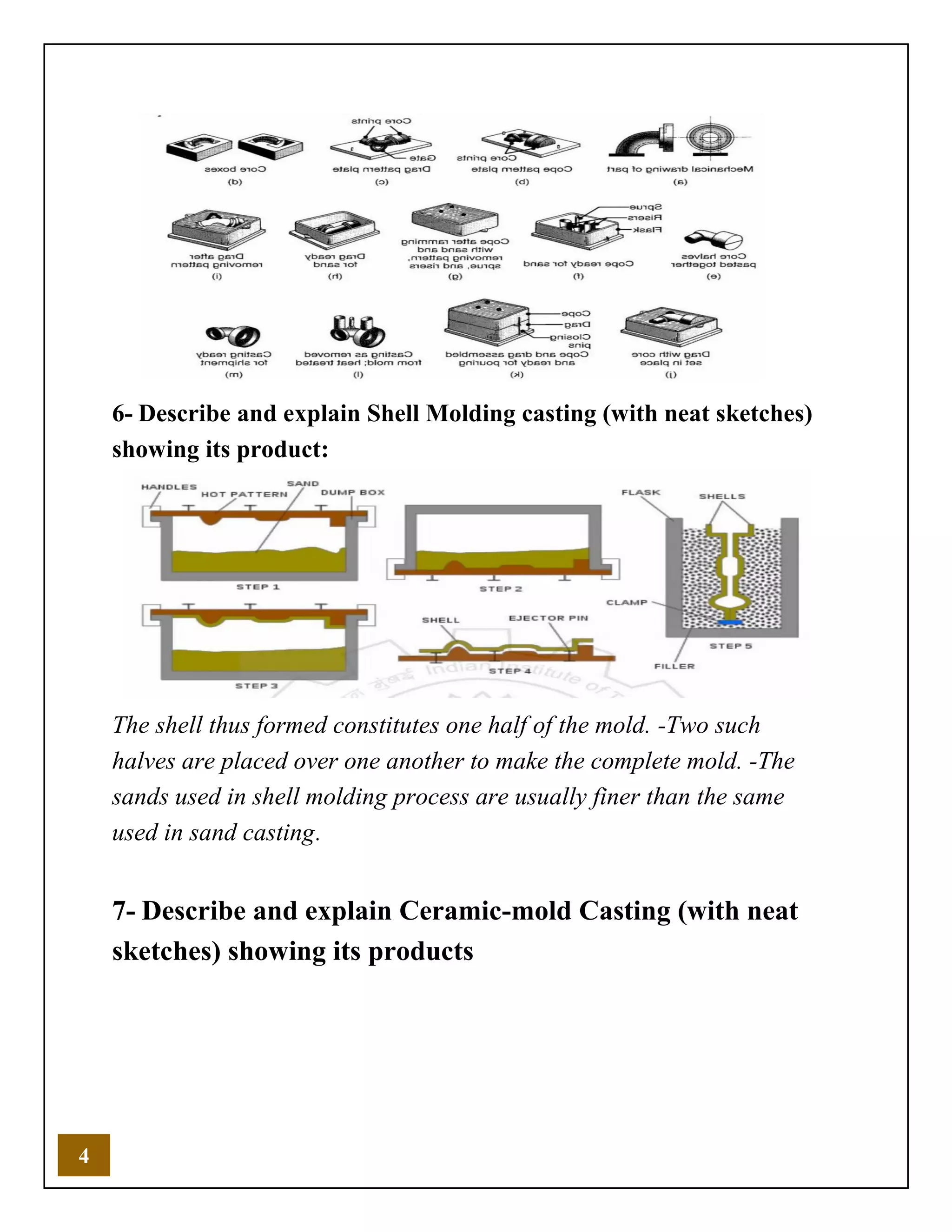

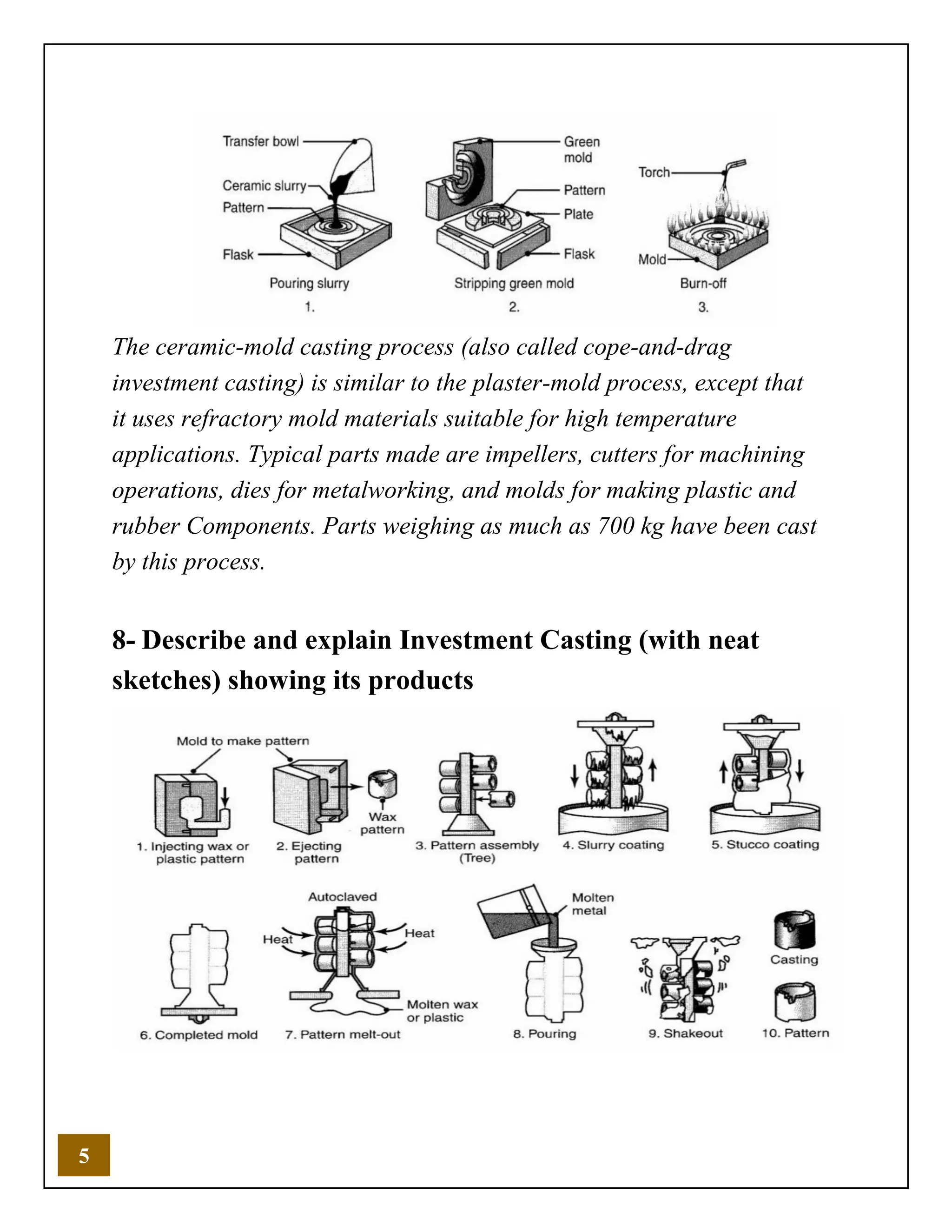

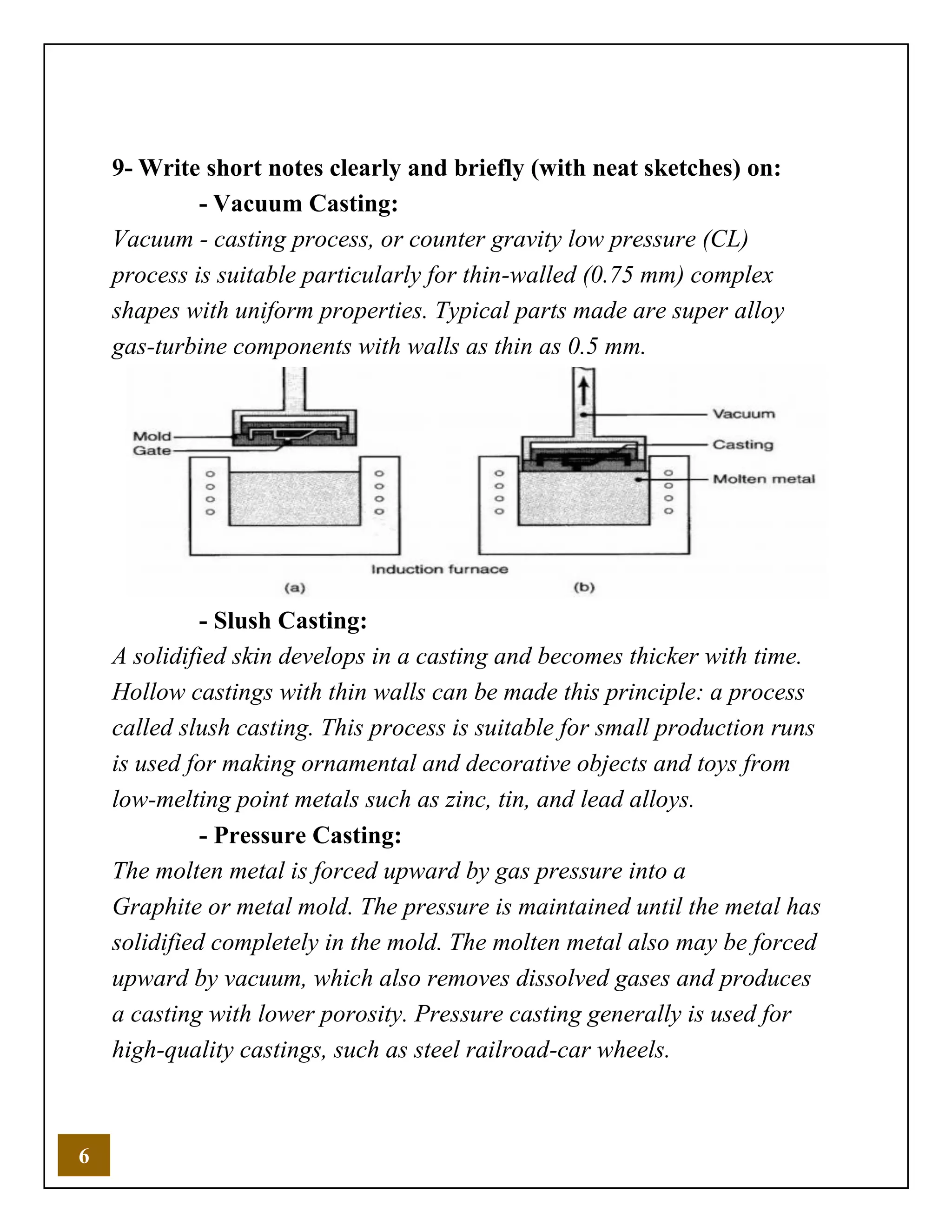

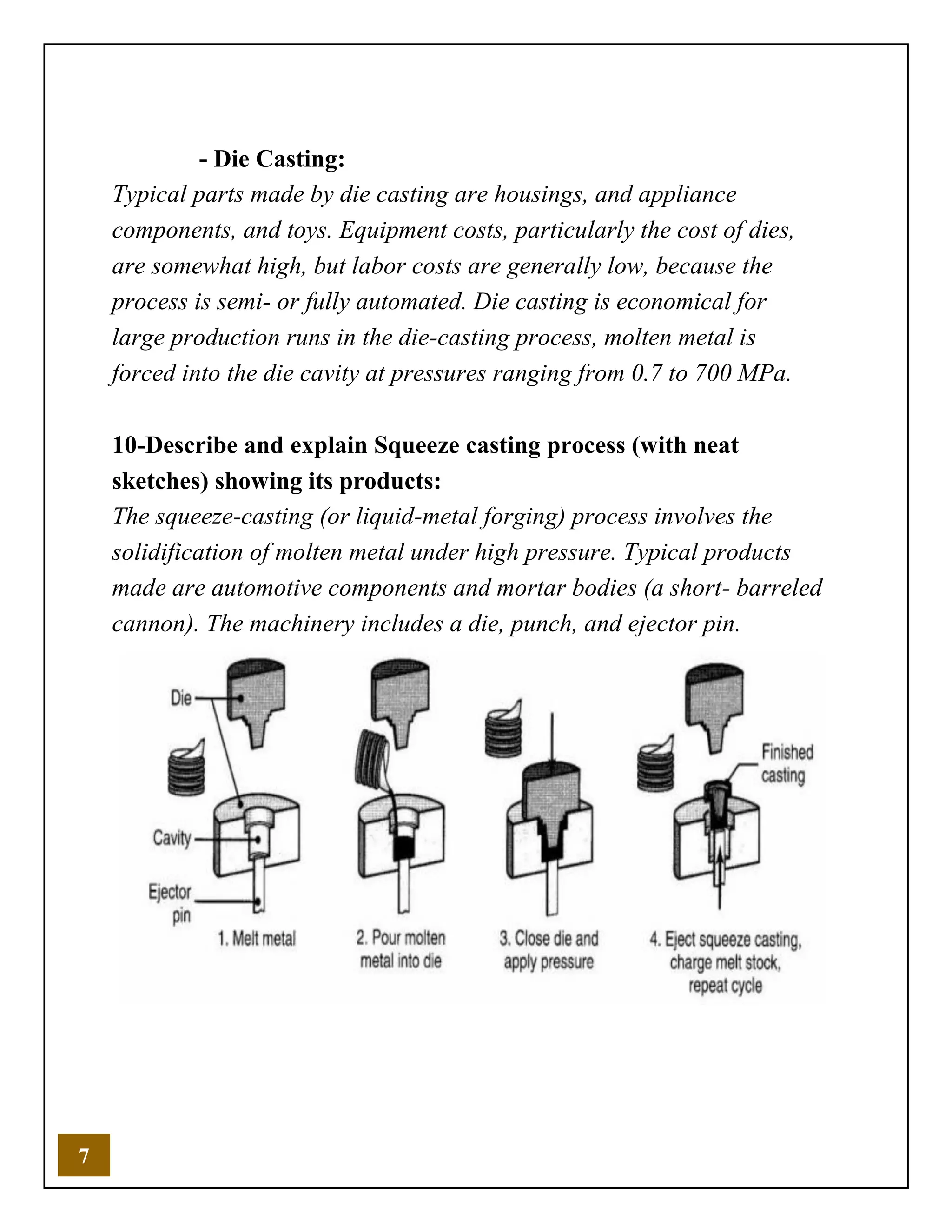

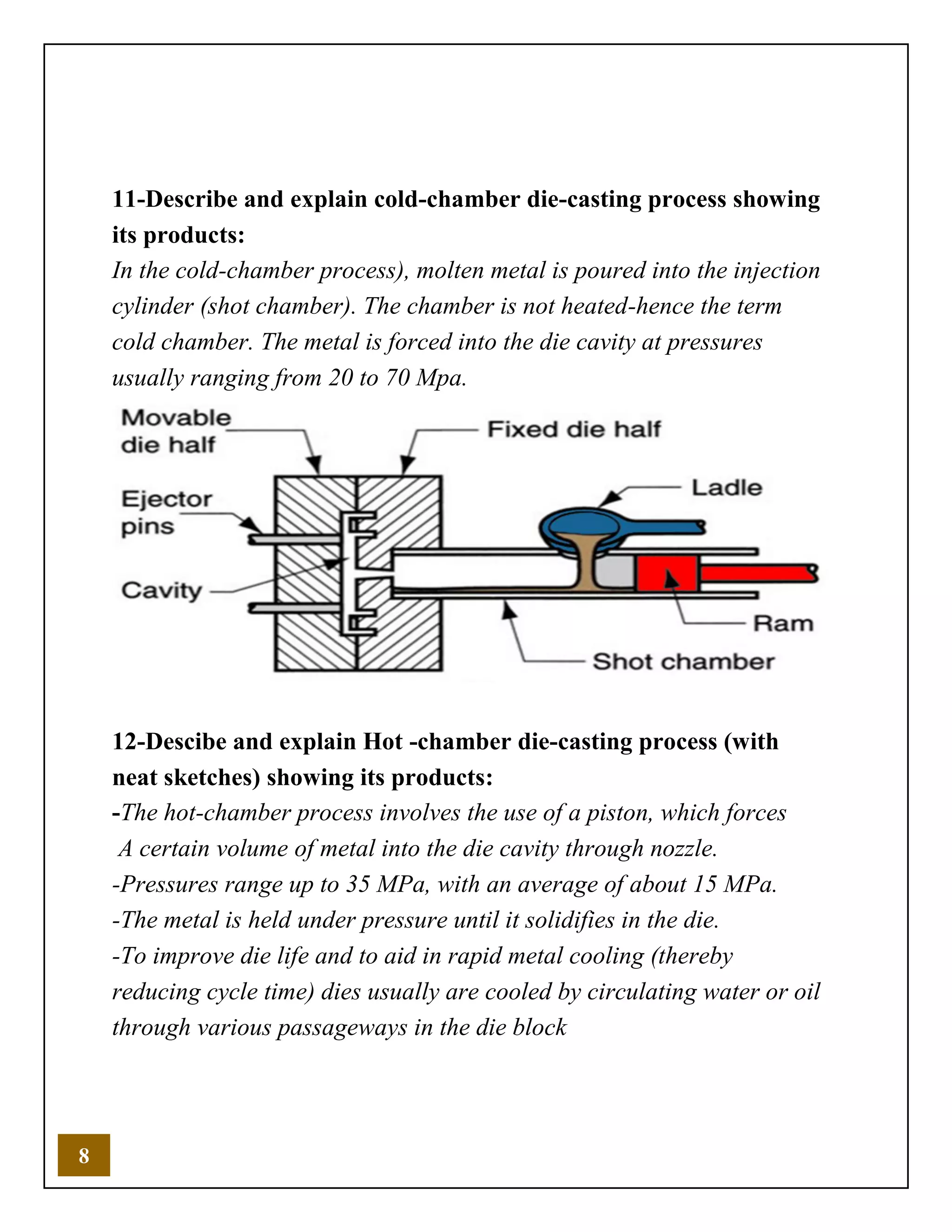

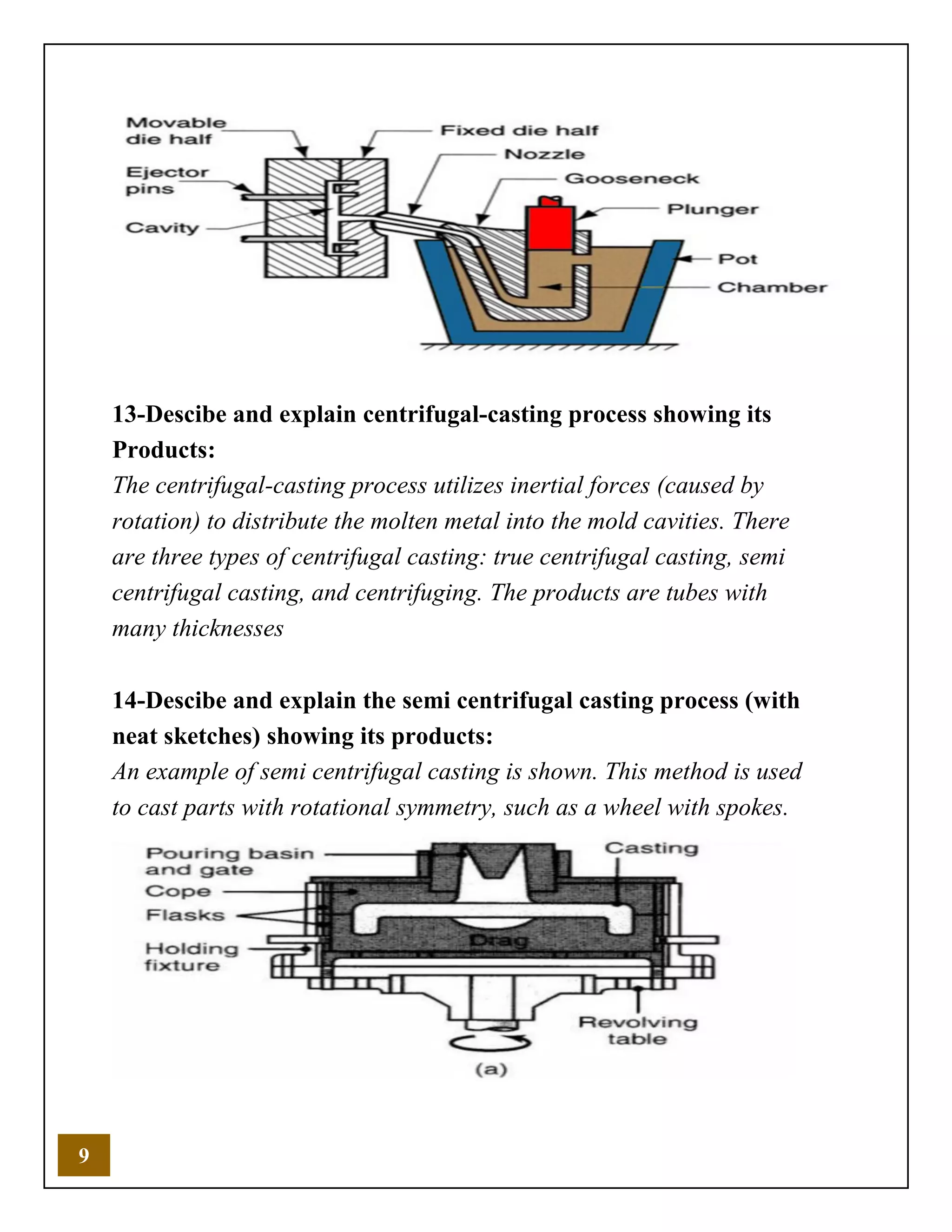

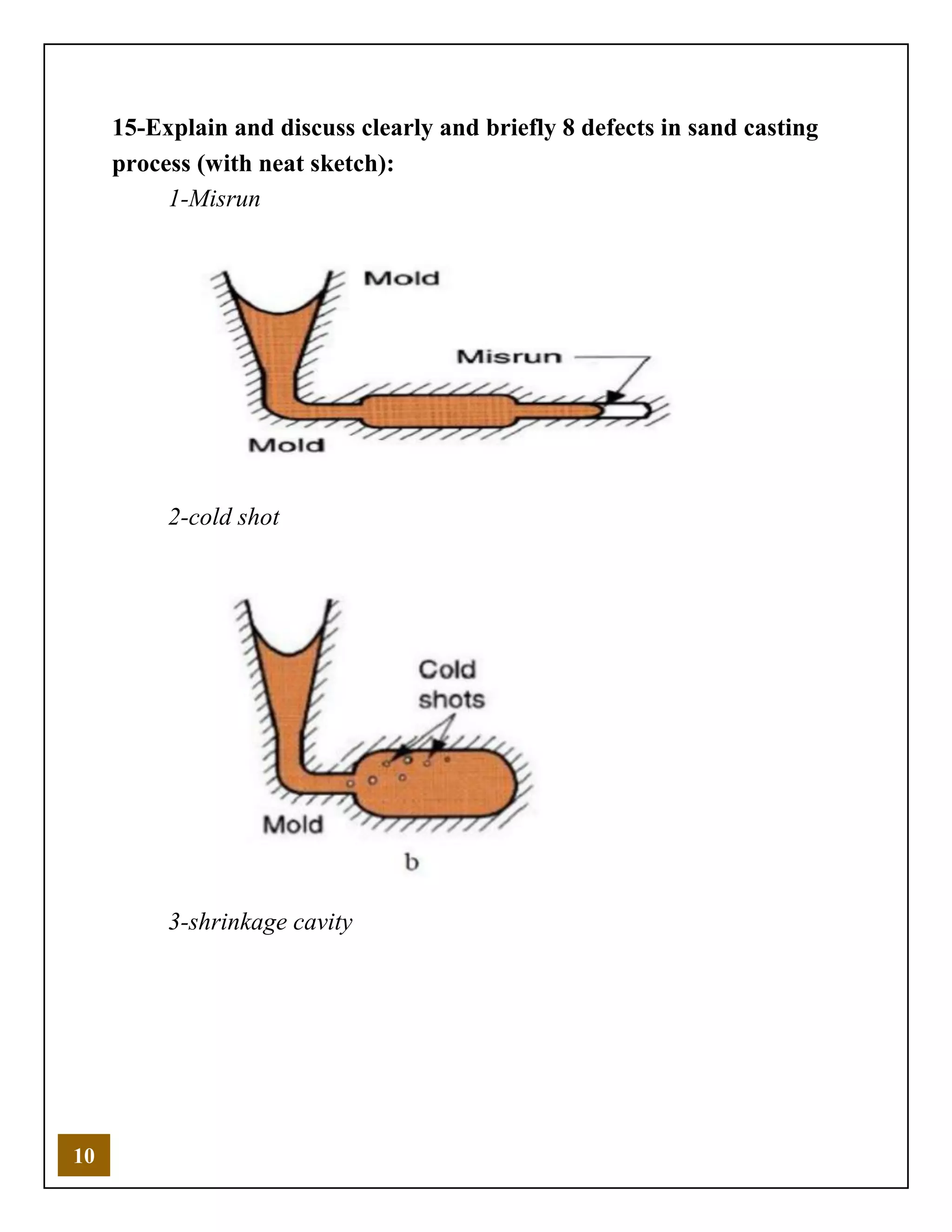

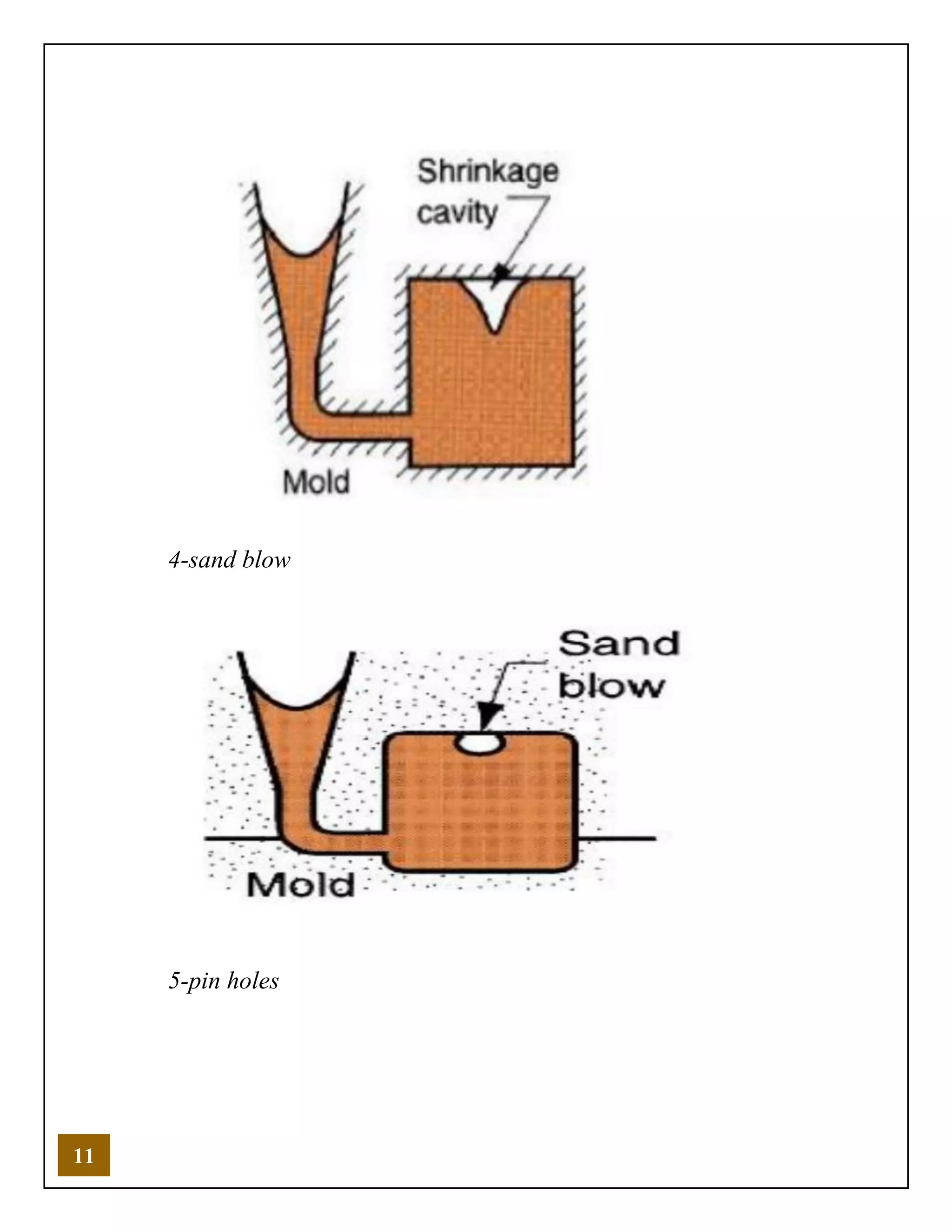

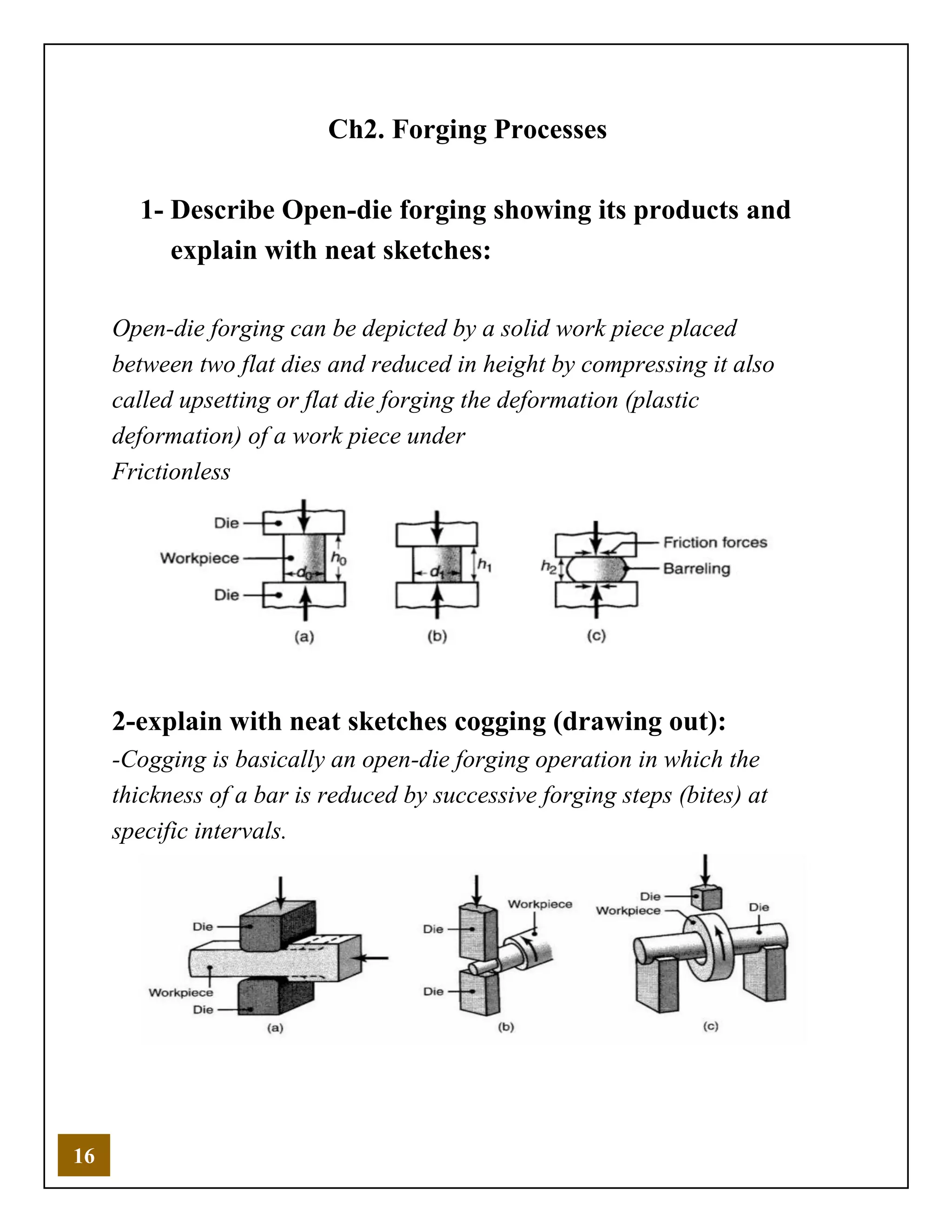

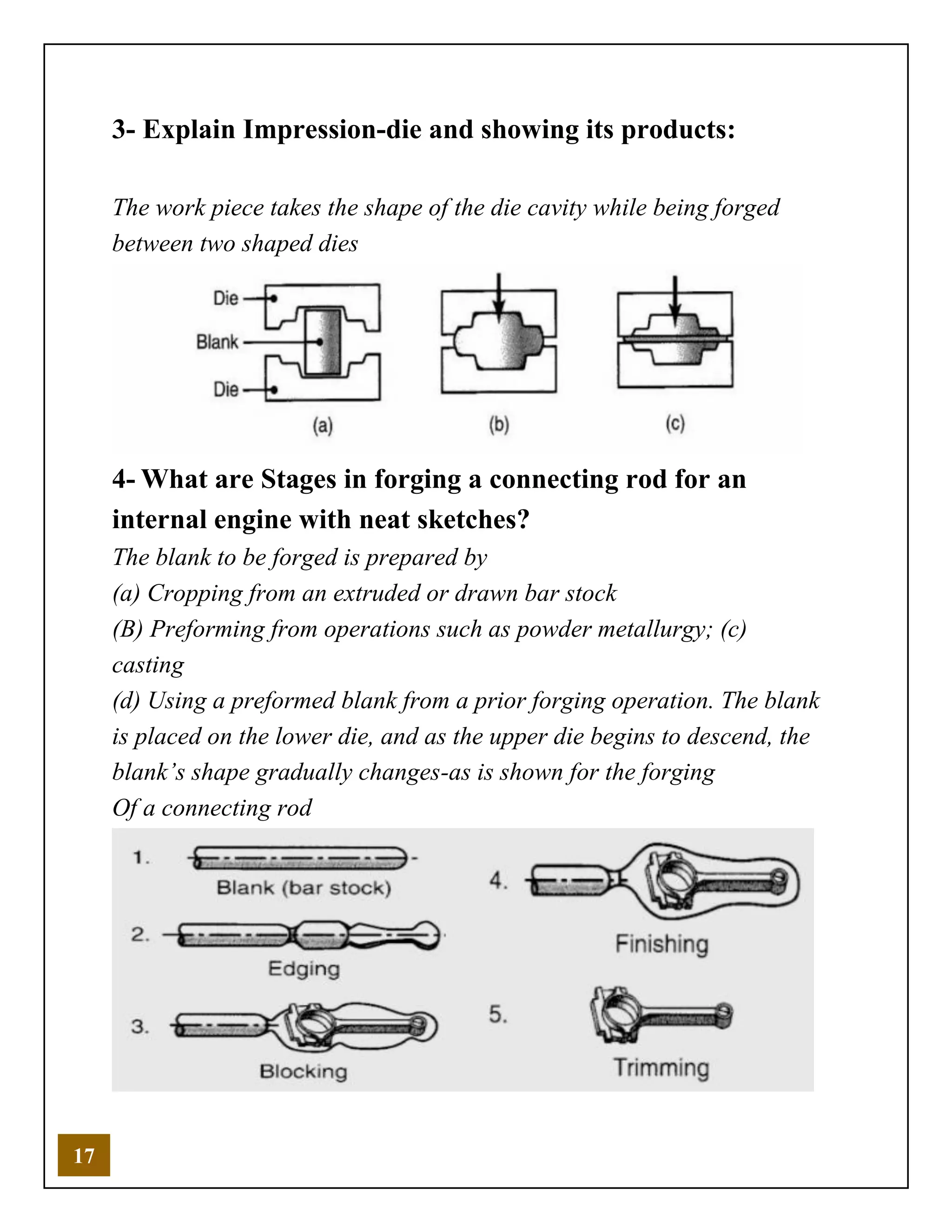

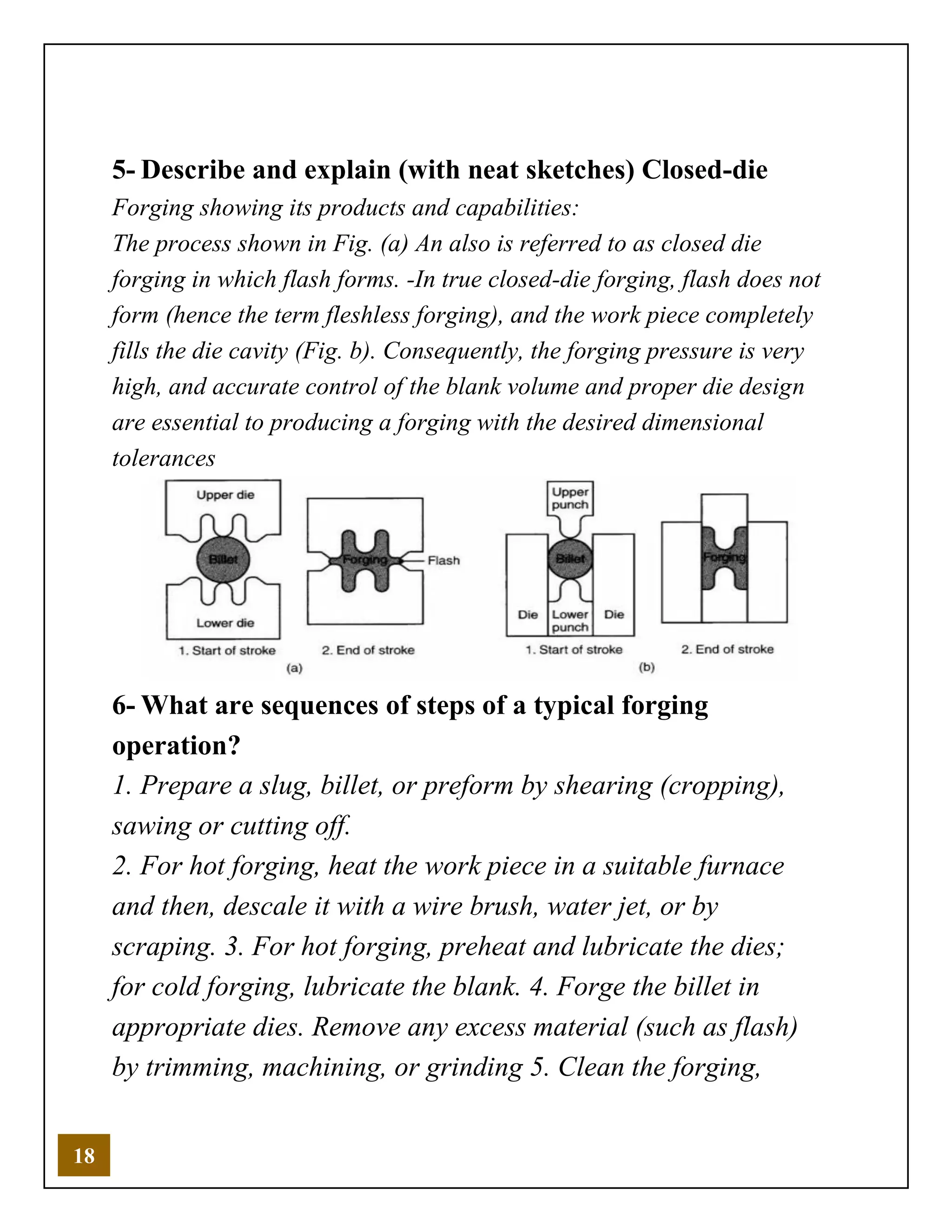

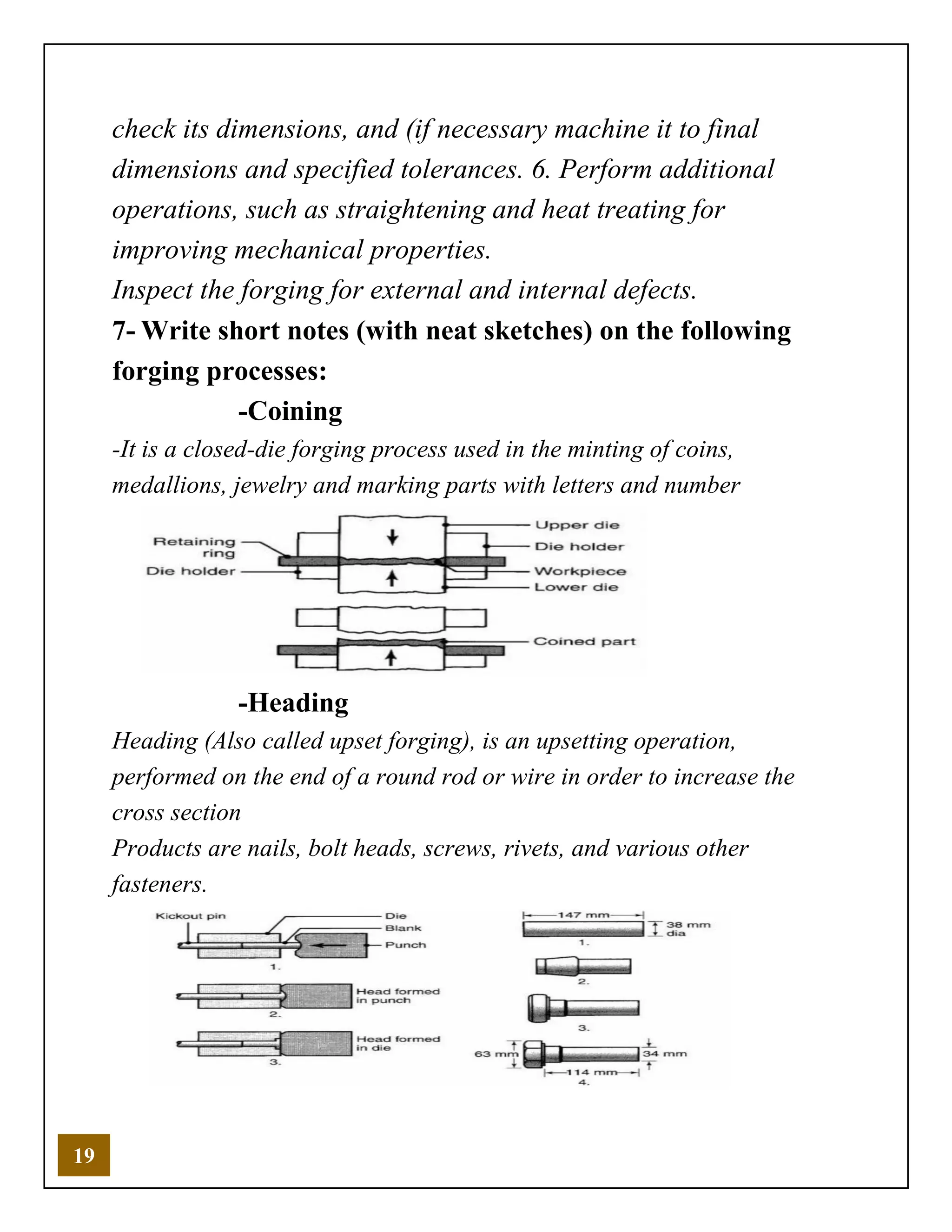

The document provides an overview of various casting and forging processes, including descriptions of molds, production steps, and typical products associated with each process. It discusses advantages and disadvantages, types of molds (expendable, permanent, and composite), and specific technologies such as investment casting, die casting, and forging methods. Additionally, it explains defects in these processes and outlines the characteristics of different types of furnaces used in metalworking.