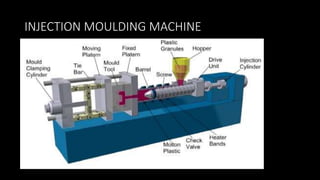

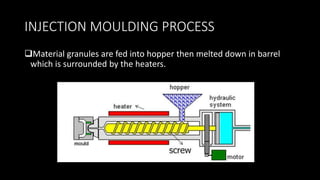

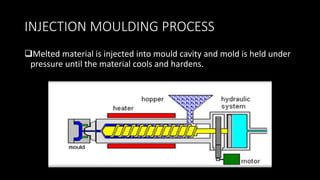

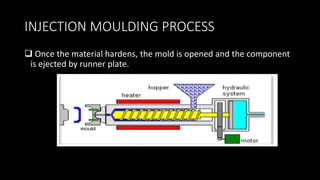

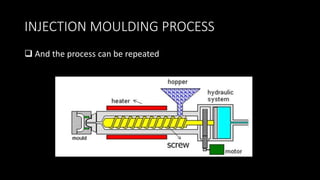

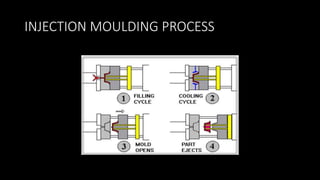

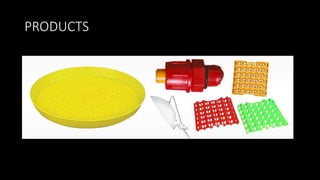

This presentation provides an overview of injection moulding. It discusses how injection moulding works by heating plastic pellets and injecting the melted plastic into a mould cavity. It describes the basic injection moulding process steps of material preparation, feeding, injection, mould holding and cooling, and ejection. Examples of common materials used and products made via injection moulding are also presented.