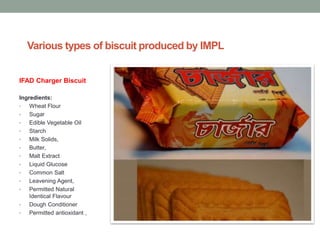

IFAD Multiproducts Limited provides industrial training to teach about food processing, manufacturing, and production. Trainees learn about unit operations, quality control, hygiene practices, and research and development. The company produces flour, water, salt, noodles, biscuits, snacks, and cake. For quality control, tests are conducted on raw materials and finished products to ensure safety, nutrition, and compliance with standards. This ensures products meet customer requirements reliably.