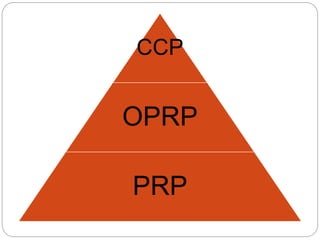

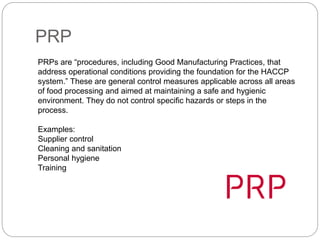

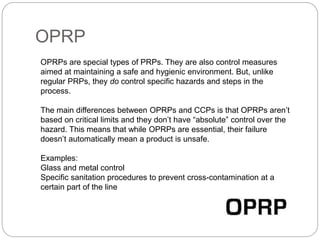

This document discusses three types of prerequisite programs for food safety: PRPs, OPRPs, and CCPs. PRPs are general control measures that maintain a safe environment but do not control specific hazards. OPRPs control specific hazards but are not based on critical limits and their failure does not automatically mean a product is unsafe. CCPs are steps that control hazards through critical limits, which if not met, would make a product unsafe.