This document provides an overview of the contents and topics covered in a course on Bakery and Confectionery Technology. The key topics discussed include:

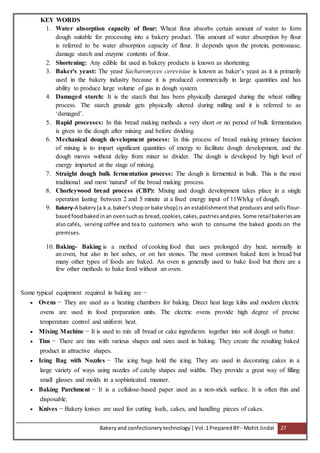

- Raw materials used in bakery products like flour, sugar, shortening, yeast, and leavening agents. The roles and specifications of these raw materials are outlined.

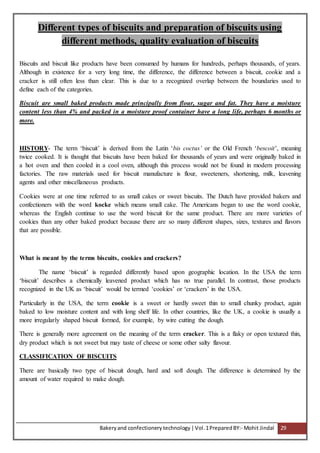

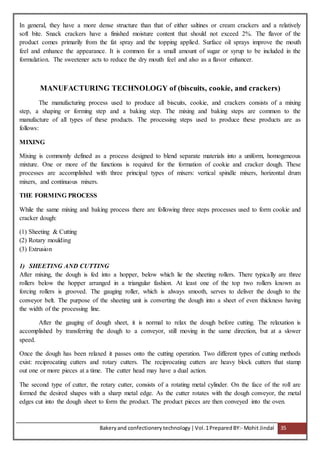

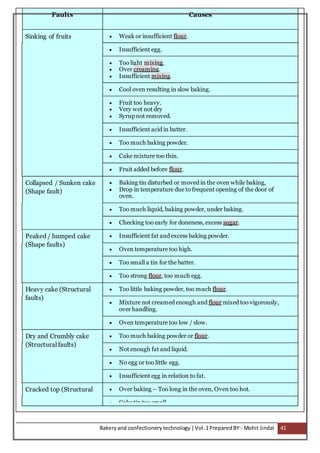

- Manufacturing processes for various bakery products like bread, biscuits, cakes, and other products. Methods for preparation, quality evaluation, and causes of staling are addressed.

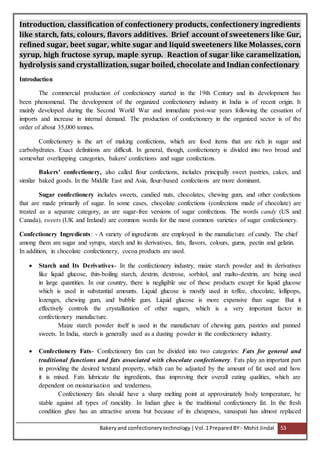

- Introduction to confectionery products, ingredients, and industry. Classification of confectionery and details about common sweeteners are provided.

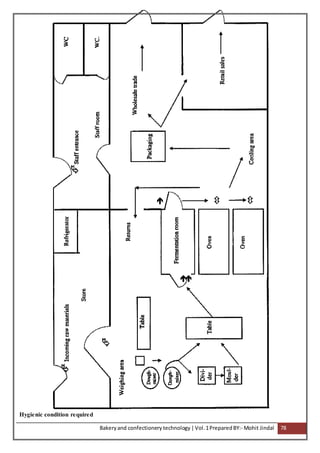

- Layout, hygienic conditions,

![Bakeryand confectionery technology |Vol.1PreparedBY:- Mohit Jindal 60

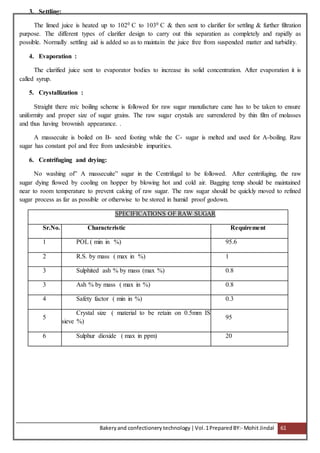

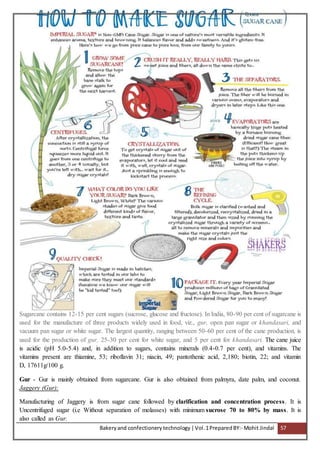

Raw Sugar- in India, sugar from sugarcane is

obtained in three forms. They are raw sugar,

refined sugar, and white sugar. Raw sugar is made

by crushing the sugarcane and extracting the juice

by pressure. The juice from the mills is dark green

in colour, turbid and acidic (pH 5.0-5.4). The

sucrose content varies from 10-18 per cent.

The raw sugar so obtained consists of brown

crystals with an adhering film of molasses. It

contains 96-97 per cent sucrose, 0.75 to 1.0 per

cent reducing sugar, and 0.5 to 0.75 per cent of

moisture, the remaining being organic non-sugars.

Raw Sugar is producing from sugar cane or

beet by ordinary process known as Defecation

process. According to Peter Rein raw sugar can

be defined as “Brown sugar produced in a raw

sugar mill generally destined for further

processing to refined sugar”.

It is Unwashed centrifugal sugar with

minimum polarization 96.5o .

Raw sugar surrounded by the original film

of molasses, to be further refined or reprocessed

for making it direct consumption sugar.

The main steps in raw sugar making process:

1. Mill sanitation:

The first important operation in the raw sugar manufacture is the “sanitation”. Every unit from mills to

conveyors is kept clean to prevent the bacterial infection. To control the growth of dextran the good quality

mill sanitation chemicals should be used in optimum dose. The growth of dextran should be controlled

through proper sanitation.

2. Defecation Process:

This is the oldest & cheapest method of juice clarification

In this process lime & heat are two basic agents.

The lime and heat treatment forms a heavy precipitate of complex composition.

Contains in soluble lime salts, coagulated albumin, and varying proportion of the fats, waxes and

gums.

Phosphoric acid is added to increase P2O5 content of juice to 300 ppm.

Then lime added to neutralize organic acids,

Besides insoluble tricalcium phosphate [Ca3 (PO4) 2] is also formed which occludes colloids &

suspended impurities.](https://image.slidesharecdn.com/bctcompiled19042018-190609081819/85/BAKERY-AND-CONFECTIONERY-TECHNOLOGY-notes-60-320.jpg)