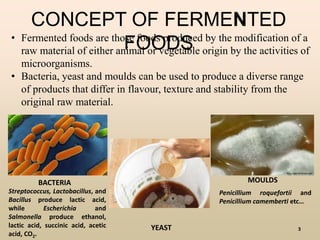

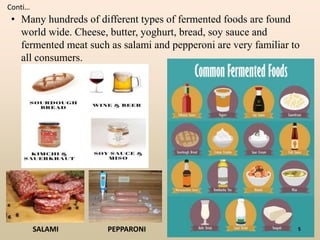

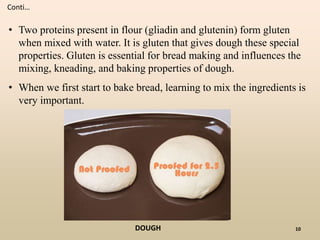

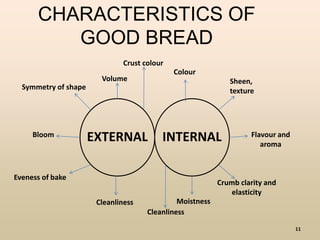

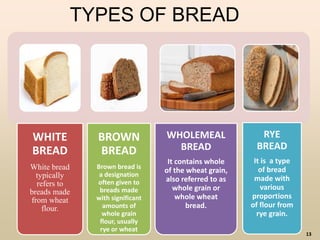

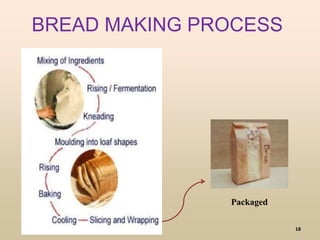

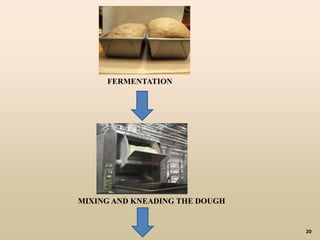

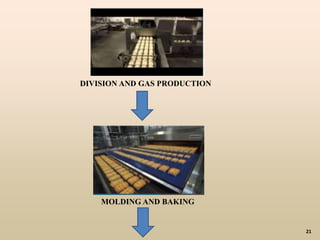

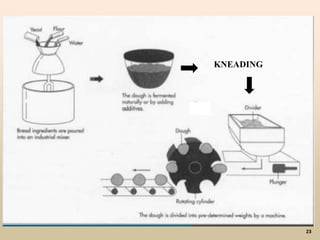

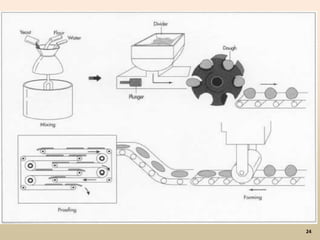

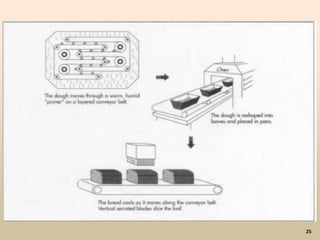

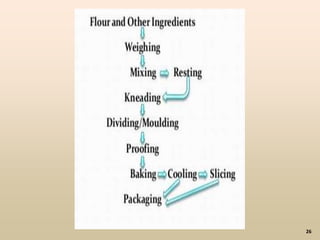

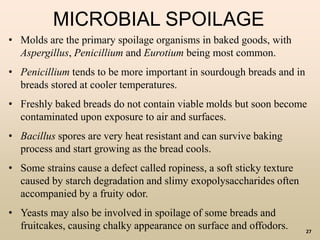

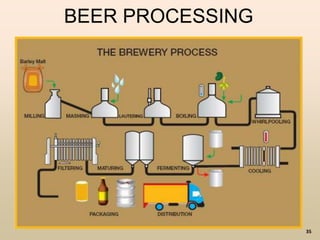

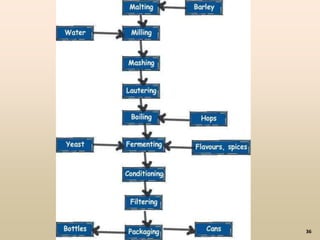

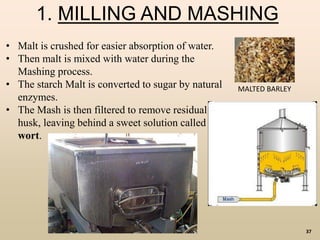

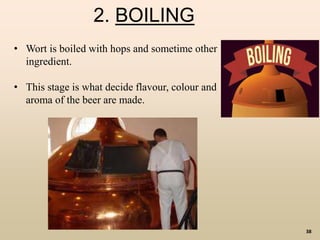

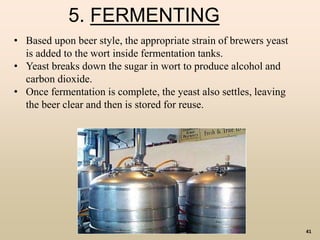

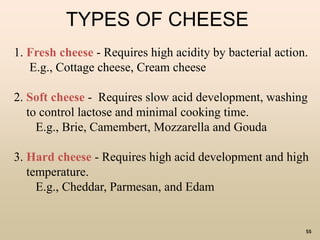

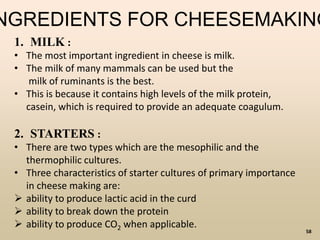

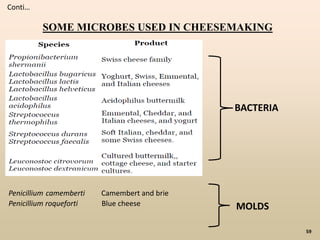

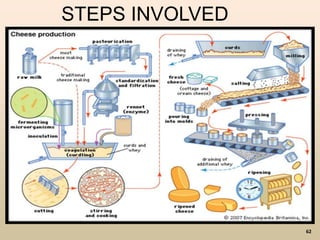

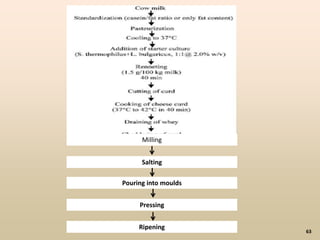

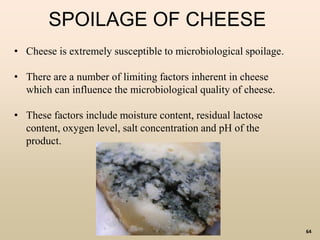

This document provides information on the manufacturing processes for various fermented foods including bread, beer, and cheese. It discusses the roles of bacteria, yeast, and moulds in food fermentation and describes the fermentation of specific foods like bread, beer, cheese, and soy sauce. The document also outlines the benefits of fermented foods for consumers and provides details on industries involved in bread manufacturing.