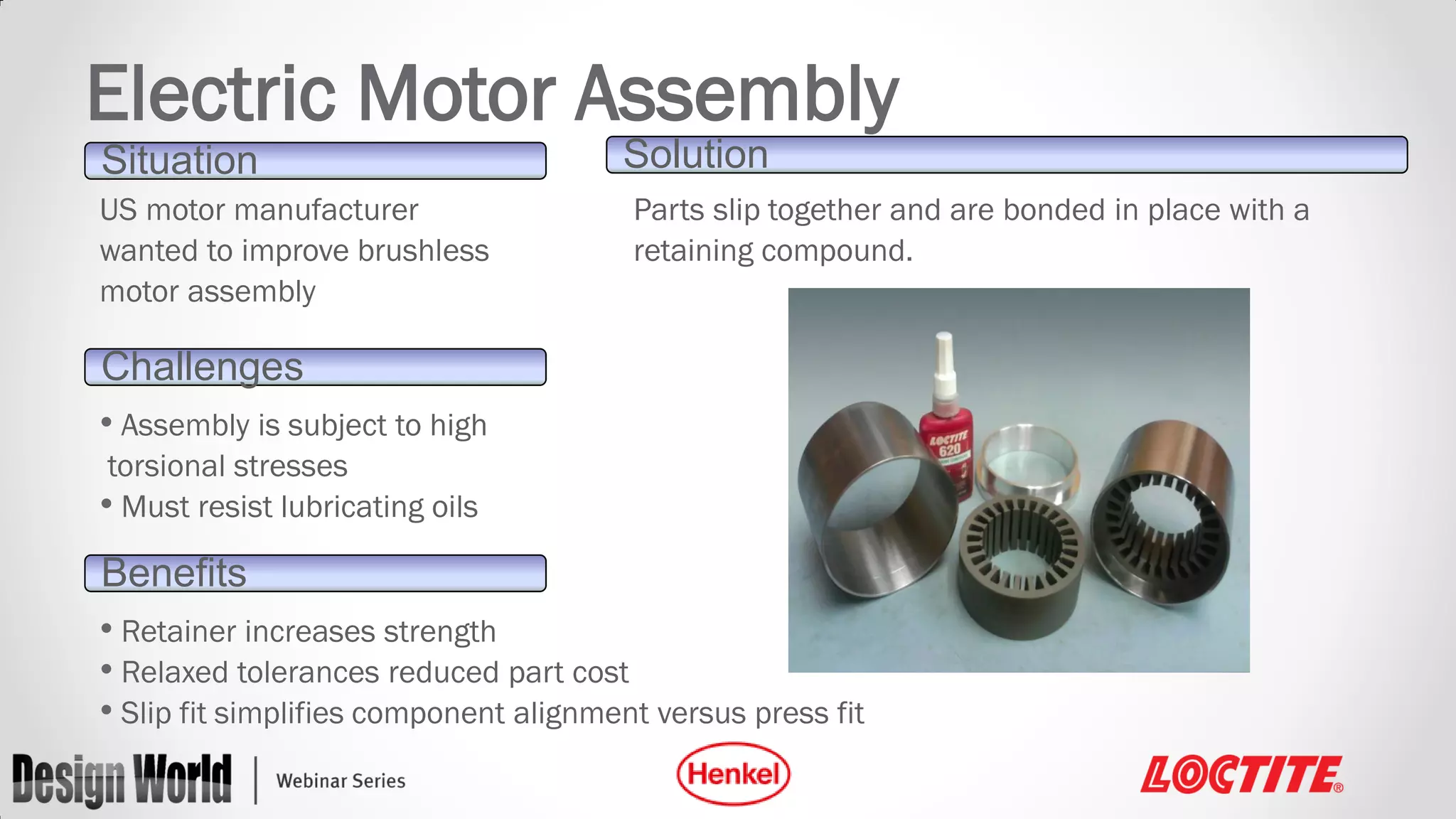

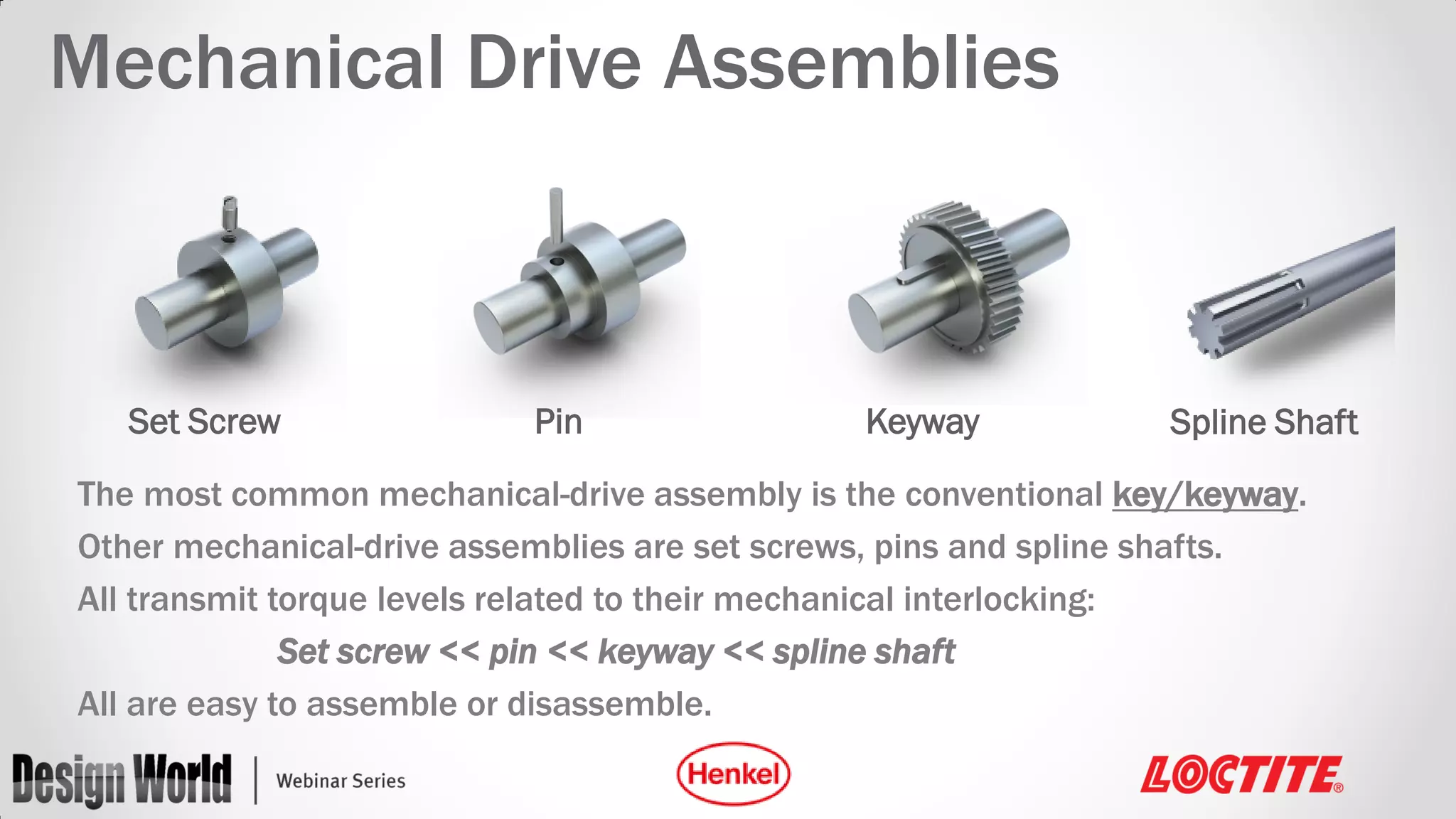

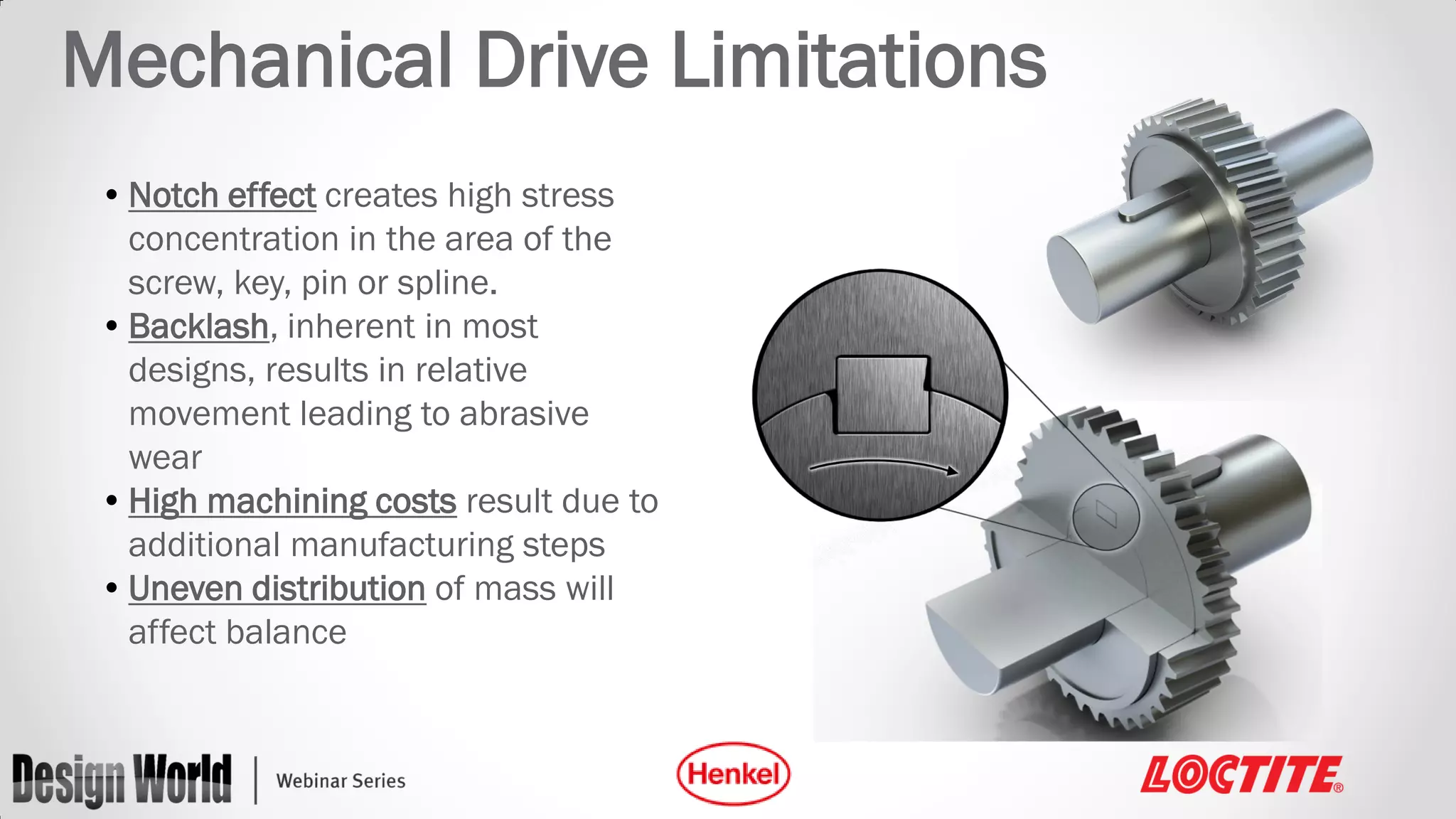

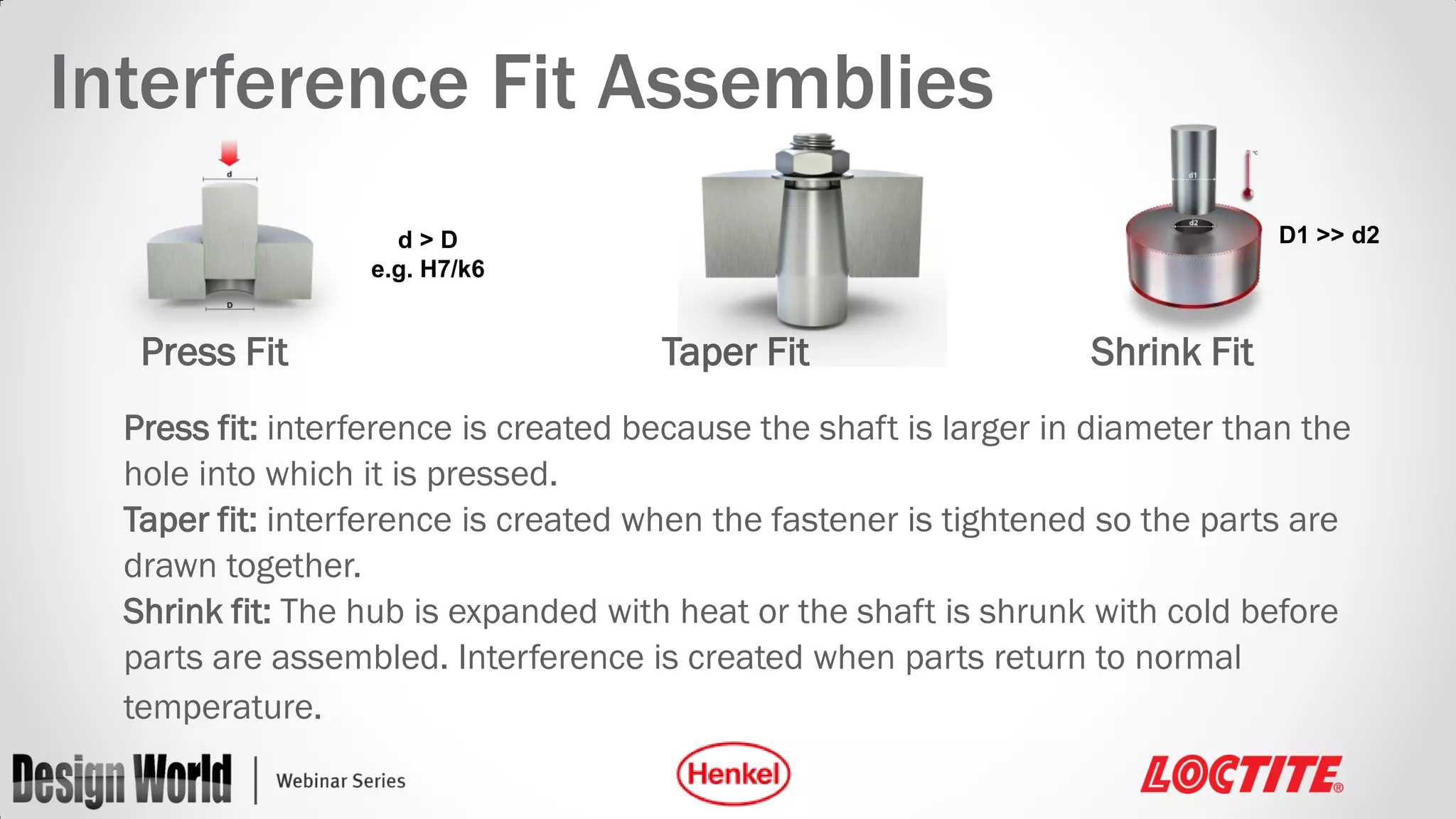

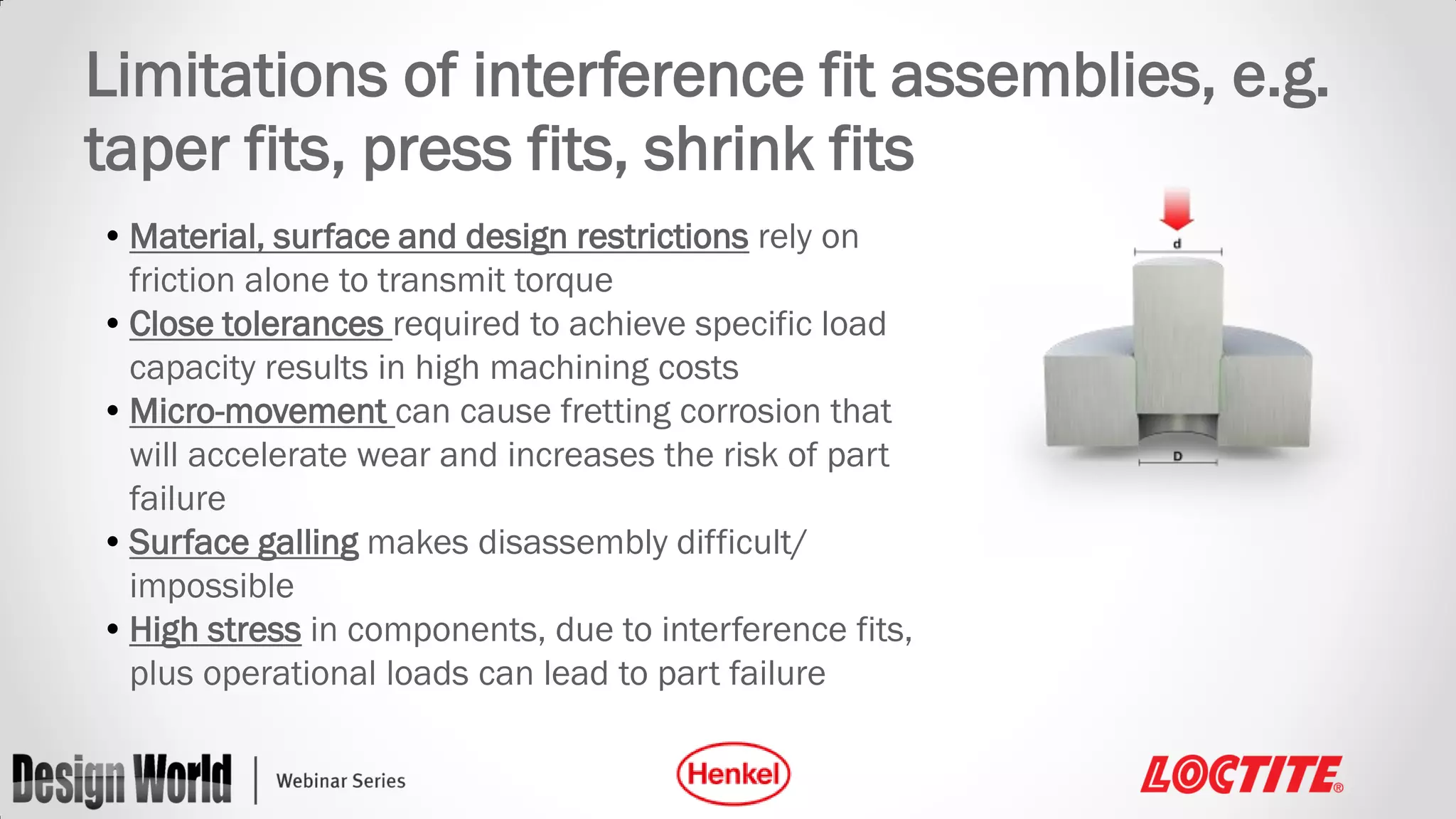

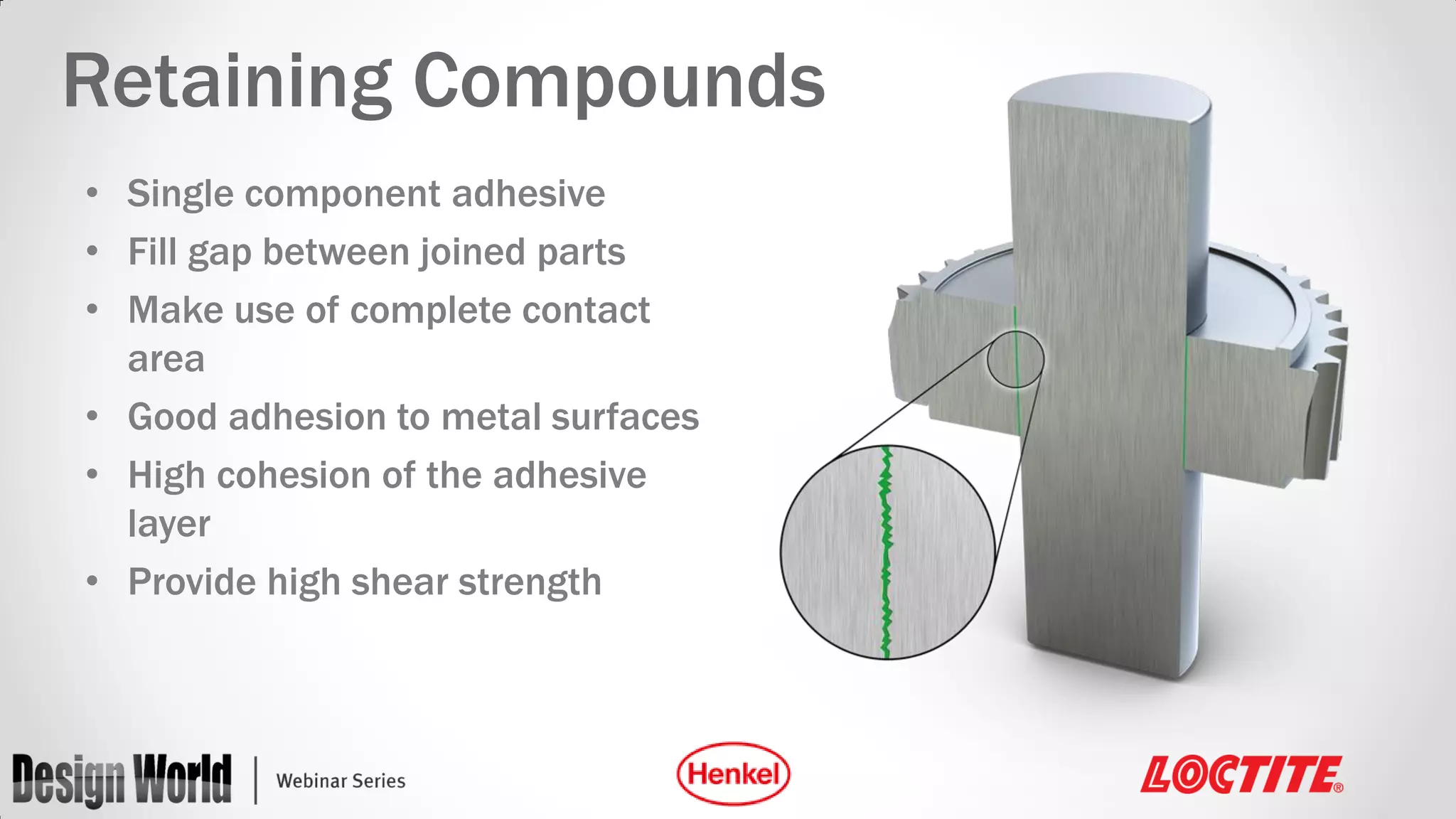

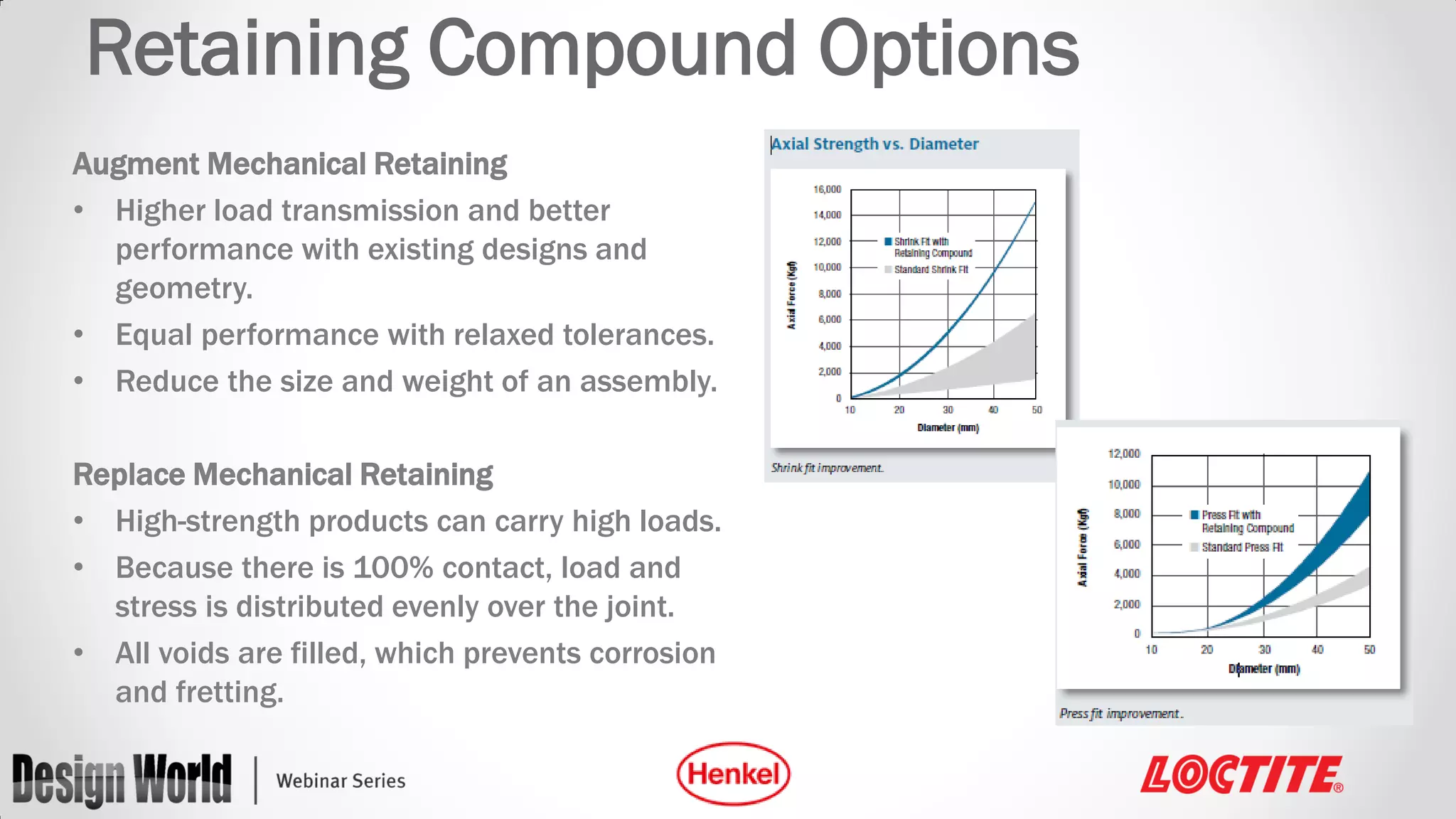

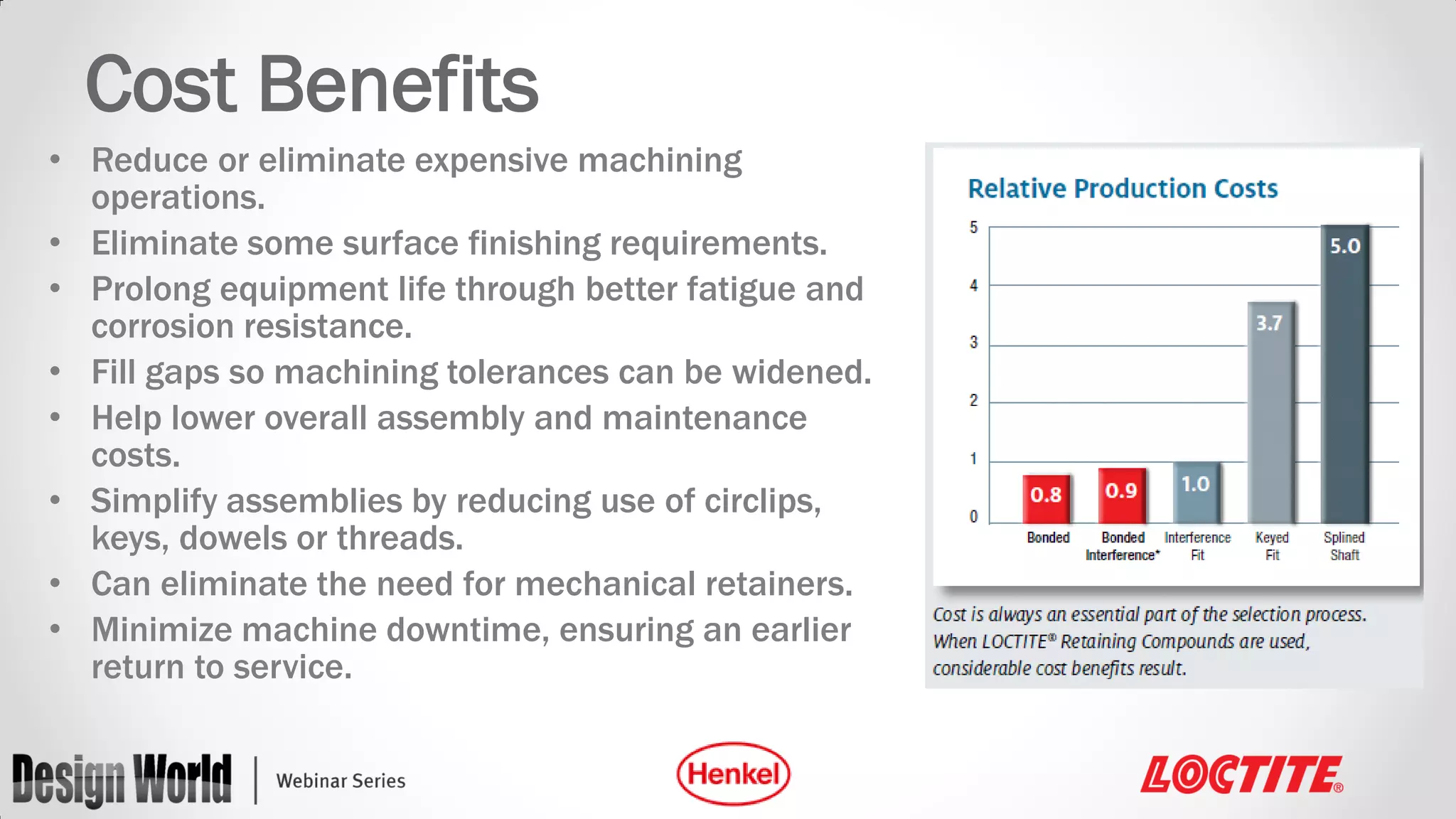

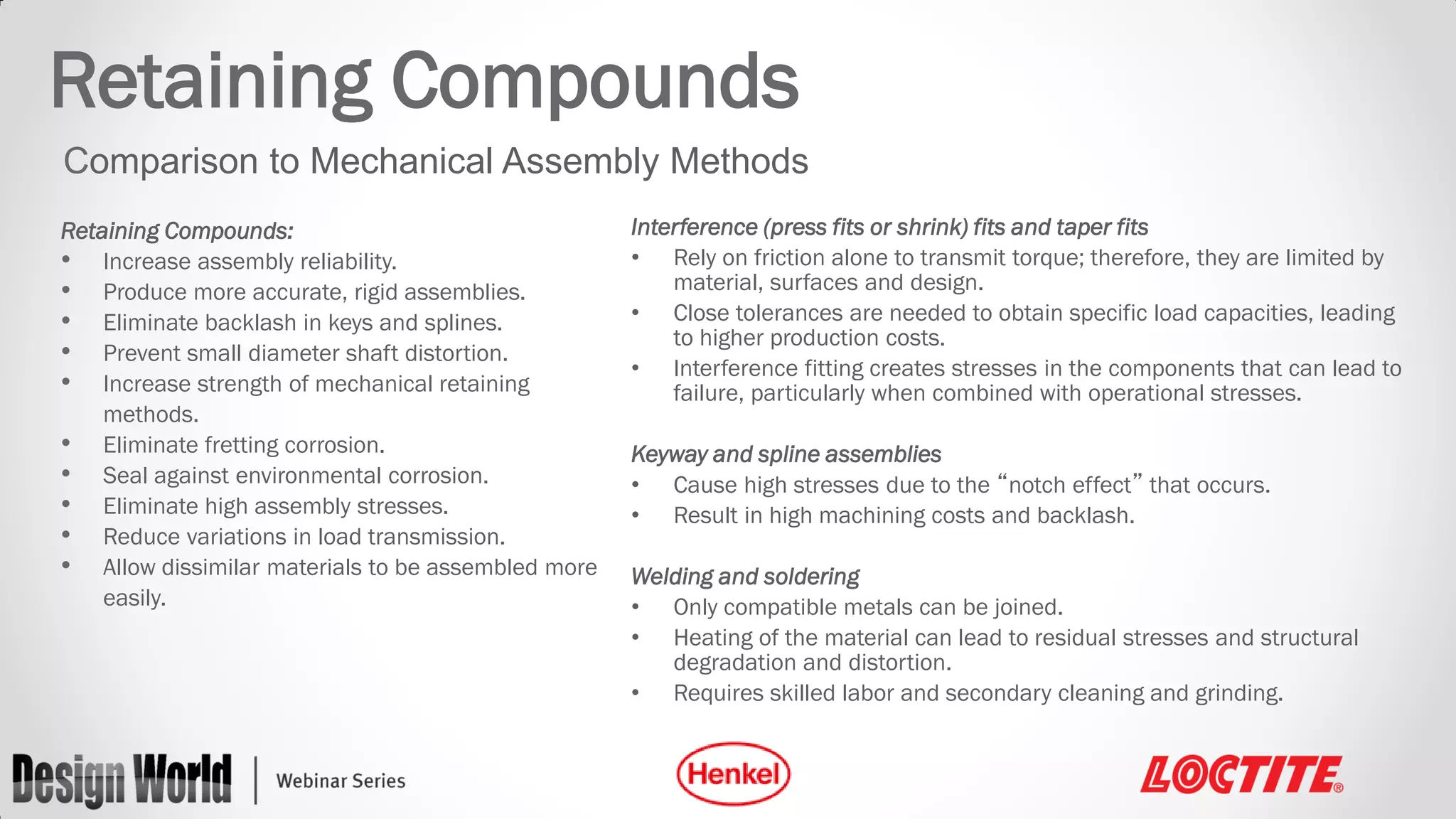

The document discusses the benefits and limitations of various mechanical retaining methods and retaining compounds for cylindrical components in engineering applications. It highlights the advantages of using retaining compounds, such as improved load transmission, ease of assembly, and enhanced longevity of parts, compared to traditional methods like press fits and welding. The webinar aims to educate attendees on these concepts and includes case studies demonstrating the application of retaining compounds in different industries.

![Disassembly

Bearings assembled with Retaining

Compound can be disassembled with

industry standard bearing disassembly

tools and techniques, including bearing

pullers and hydraulic presses.

Another technique is to heat the parts well

above the service temperature [to 250°C

(482°F) for most products] and

disassemble while the parts are hot.](https://image.slidesharecdn.com/2013-11-14-henkelloctite-press-fits-b-131122124309-phpapp02/75/Increasing-the-Strength-and-Reliability-of-Press-Fits-19-2048.jpg)