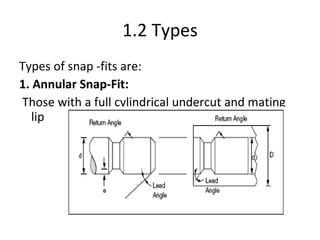

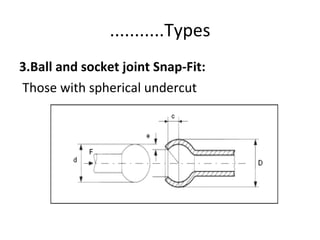

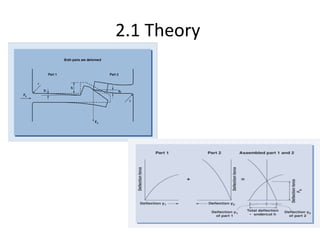

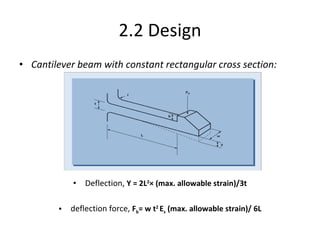

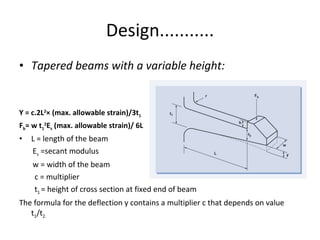

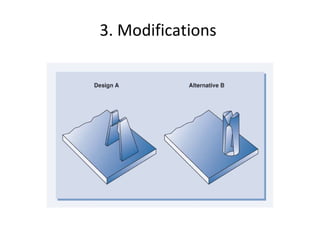

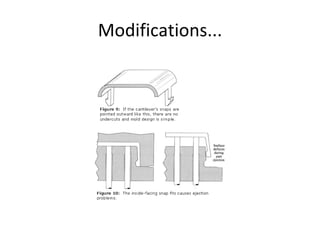

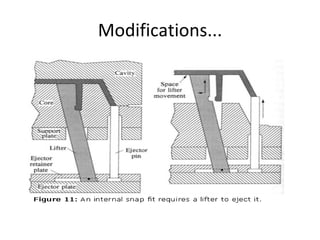

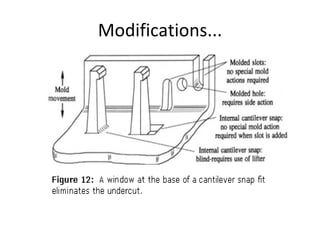

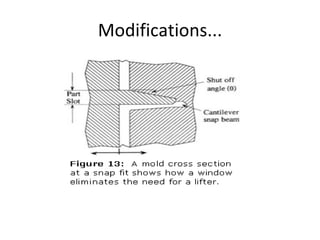

This document summarizes a presentation on snap fit design. It discusses what a snap fit is, the different types of snap fits, and their applications. It then covers key design features for snap fits, including theoretical considerations, design guidelines, and material selection. Specifically, it discusses factors like strain limits, stress concentrations, friction, and lead and return angles that influence mating and separation forces. The document provides equations for calculating deflection and forces. It also discusses design of cantilever and tapered beam styles and choosing thermoplastics as ideal materials. Finally, it lists some modifications to consider for snap fits.