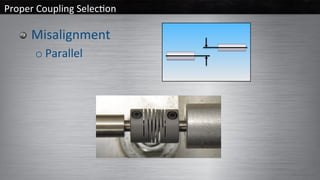

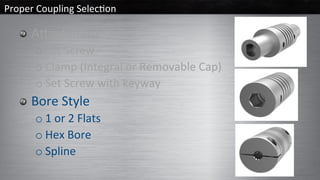

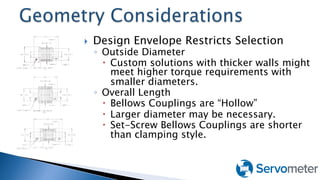

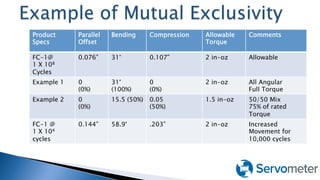

This document outlines a webinar focused on proper coupling selection as an integral part of system design, emphasizing the importance of considering torque capacities, misalignment capabilities, and environmental factors. It discusses various types of couplings, specifically bellows couplings by Servometer, including their construction, specifications, and applications. Additionally, the document includes insights into custom coupling solutions, key performance metrics, and guidelines for optimal coupling selection.