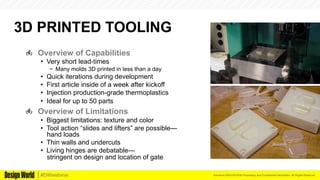

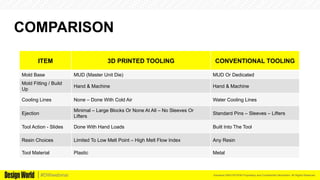

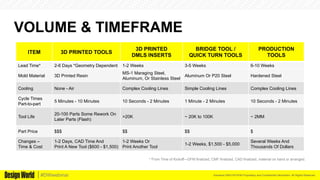

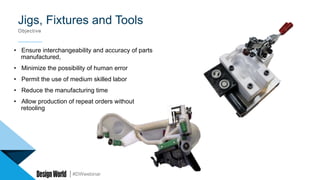

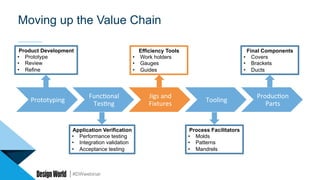

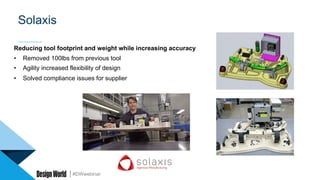

This webinar discussed how 3D printing can be used to create jigs, fixtures and tools to streamline manufacturing processes. It highlighted challenges with traditional manufacturing aids like long setup times and presented how 3D printing enables complex geometries, design flexibility, and part consolidation. Customer examples were provided where 3D printing reduced costs and lead times for tooling components at Triumph Composite Systems and optimized robotic end-of-arm tooling at Genesis Systems Group. The webinar recommended connecting cross-functional teams to identify opportunities for 3D printed tools and focusing first on implementing them in one department.