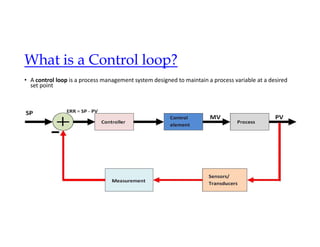

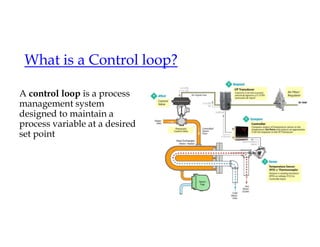

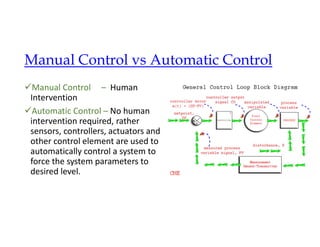

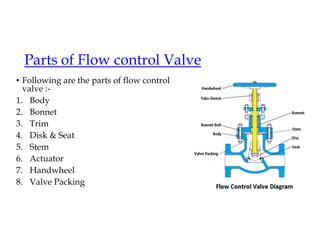

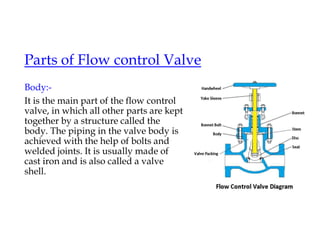

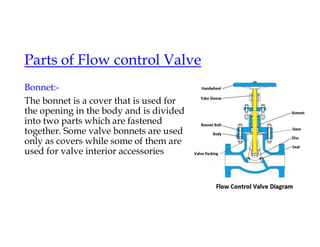

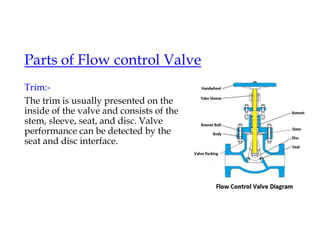

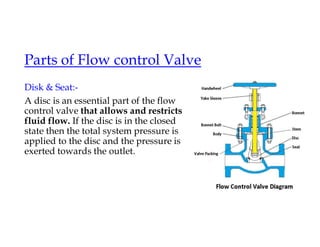

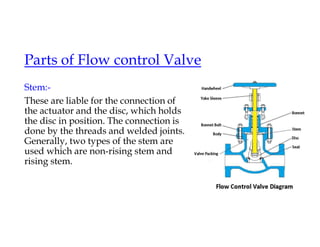

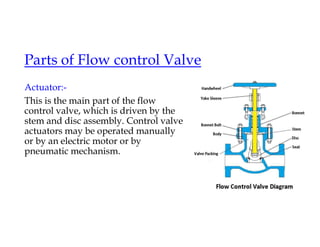

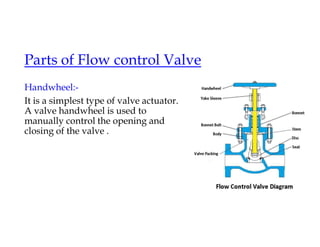

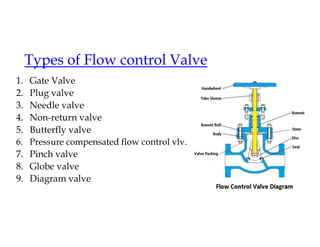

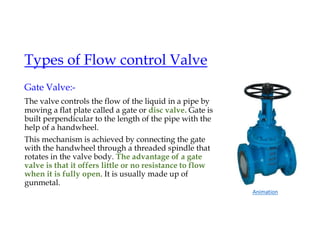

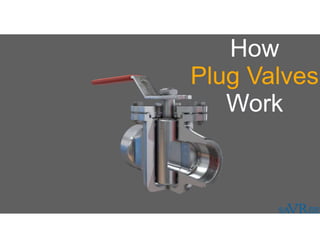

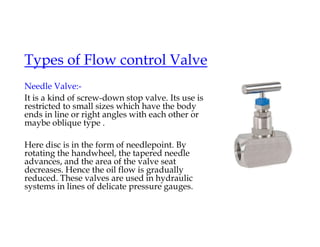

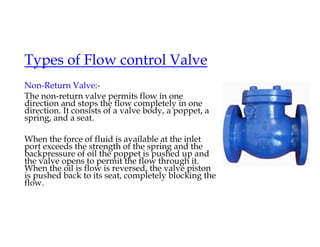

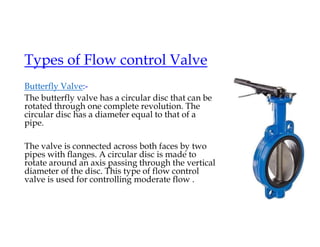

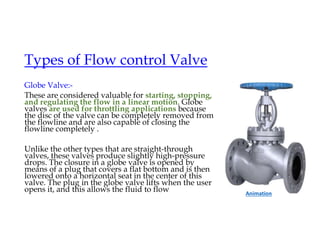

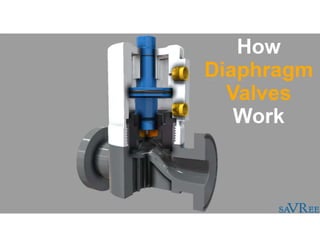

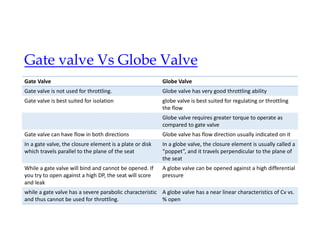

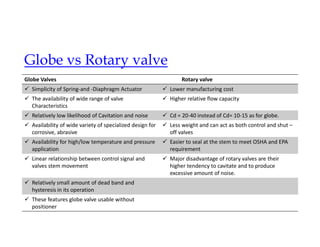

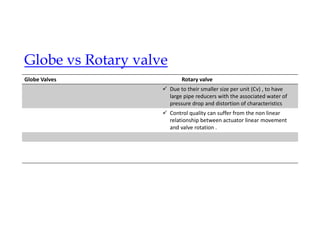

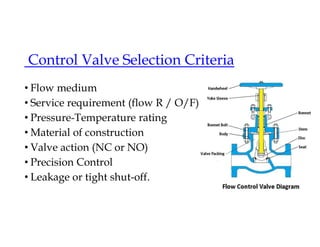

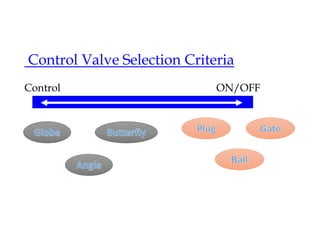

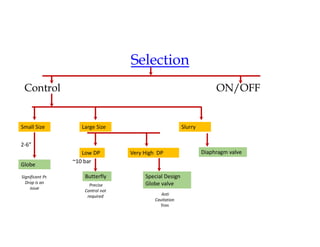

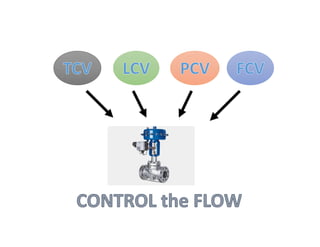

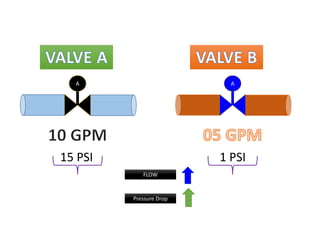

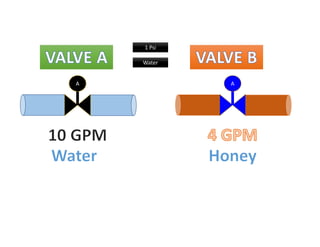

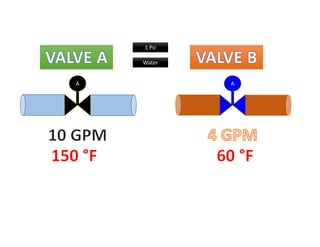

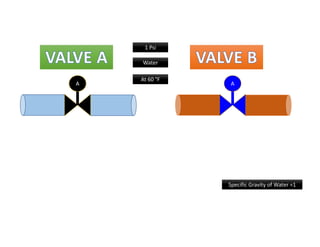

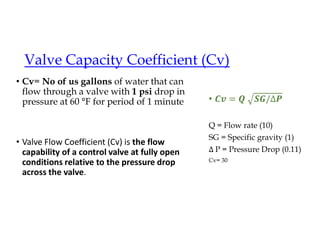

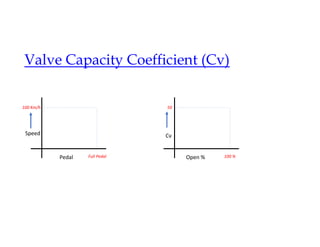

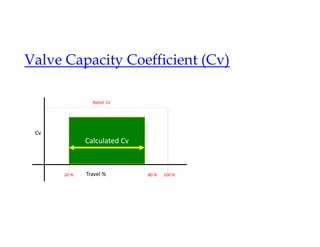

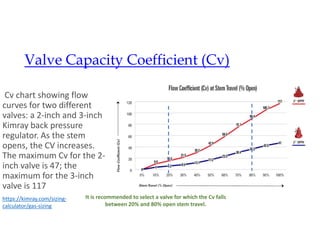

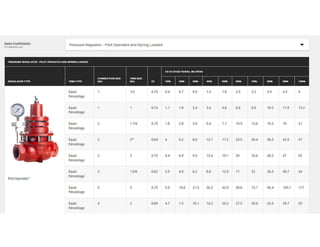

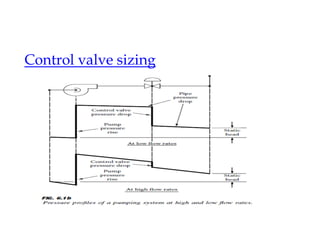

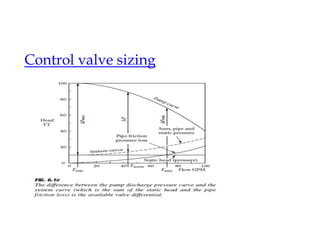

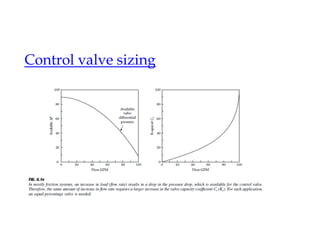

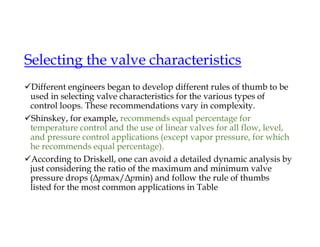

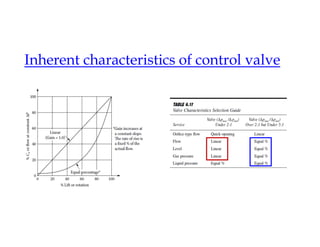

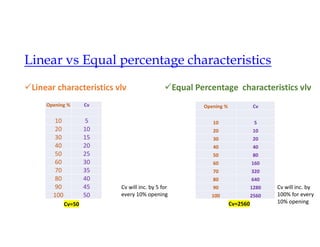

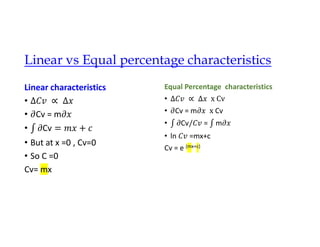

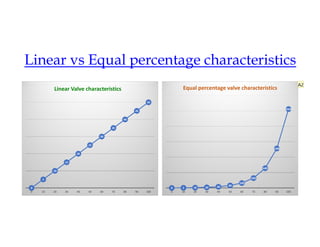

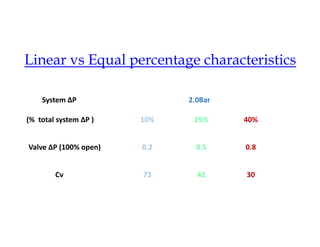

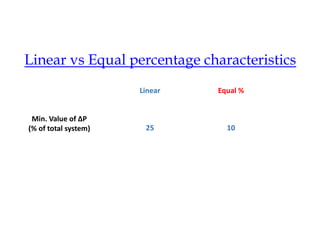

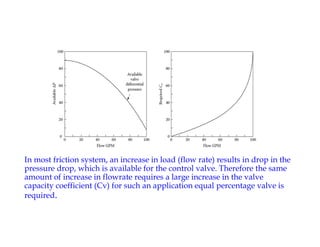

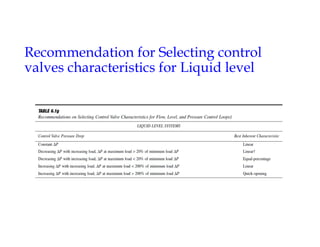

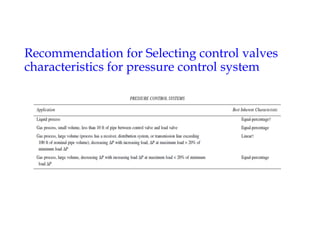

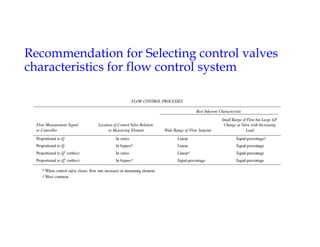

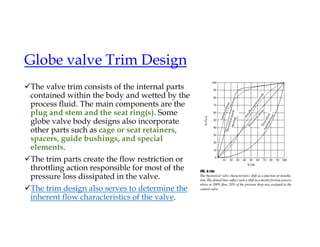

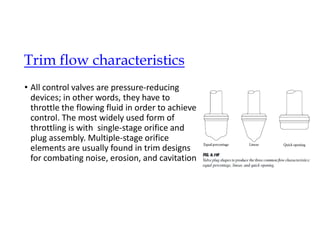

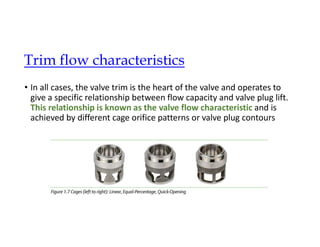

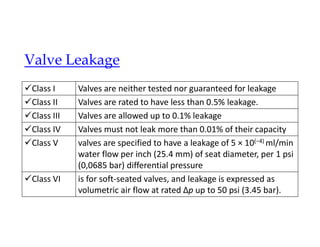

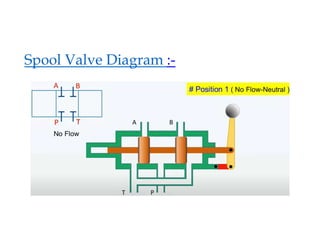

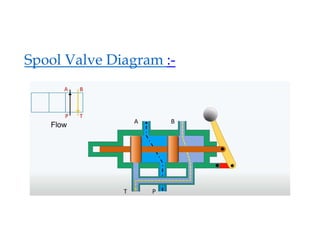

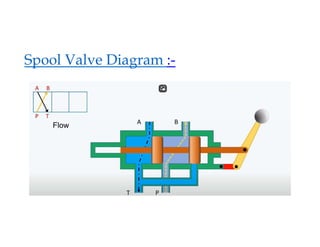

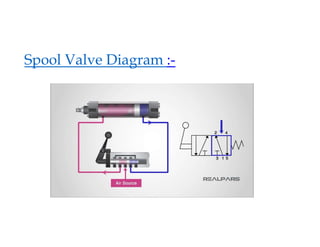

This document covers various aspects of control valves, including their definition, components, operation, and types. It explains the control loop process, differentiates between manual and automatic control, and details specific types of flow control valves like gate, plug, needle, and globe valves along with their applications. Additionally, it discusses control valve selection criteria, sizing considerations, and the importance of valve capacity coefficient (cv) for effective flow regulation.