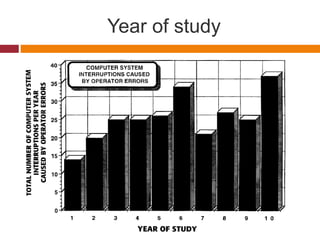

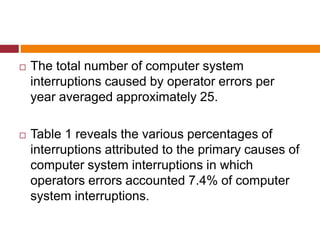

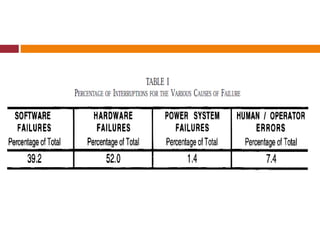

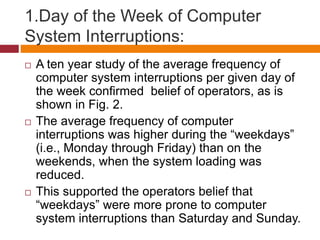

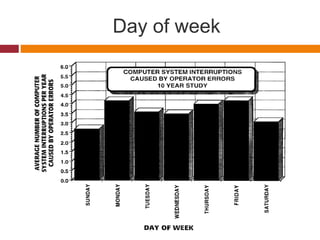

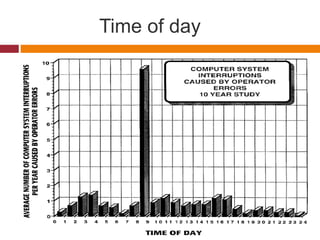

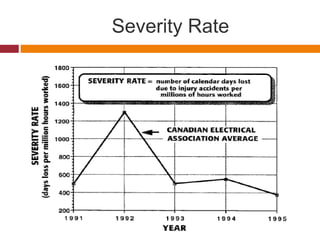

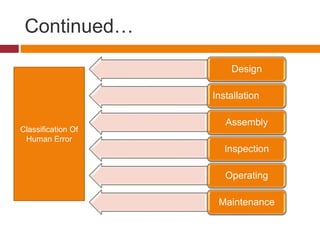

The document discusses the critical role of human factors in the reliability and safety of man-machine systems, highlighting that 20% to 50% of equipment failures stem from human errors. Case studies reveal significant interruptions in computer systems and utility distributions due to operator mistakes, emphasizing the need for improved training and adherence to safety protocols. It outlines various classifications of human errors, their impact on operational integrity, and preventative measures to mitigate risks associated with human factors in industrial settings.