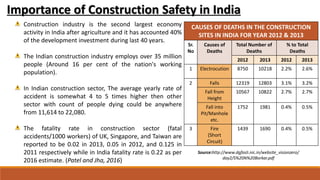

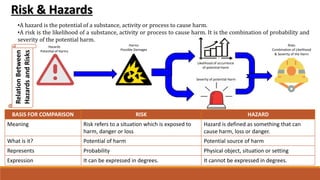

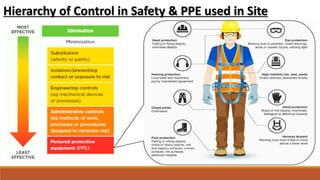

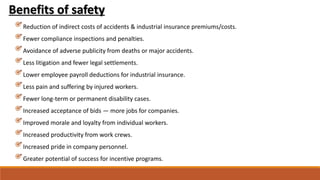

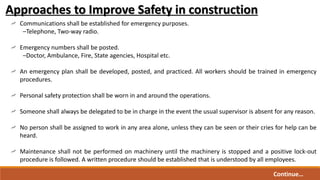

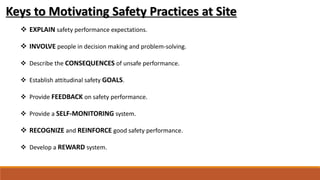

The document emphasizes the critical importance of safety management in the Indian construction industry, which employs over 35 million people and experiences significantly higher accident rates compared to other sectors. It outlines causes of construction accidents, defines risks and hazards, and discusses approaches to enhance safety measures, including the implementation of personal protective equipment (PPE) and the establishment of emergency plans. The benefits of improved safety practices include reduced costs, increased morale, and enhanced productivity within the workforce.