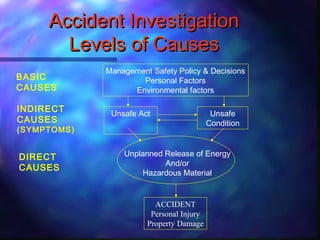

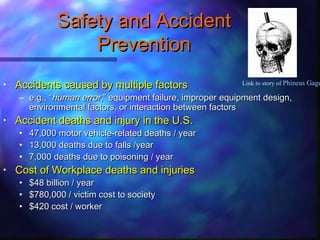

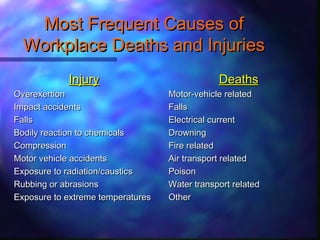

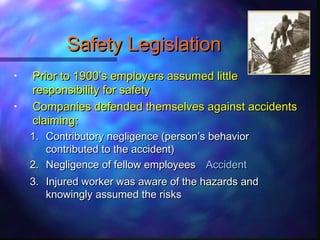

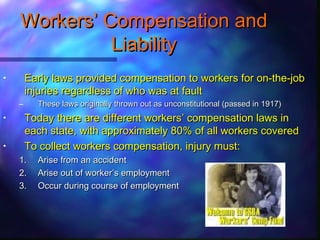

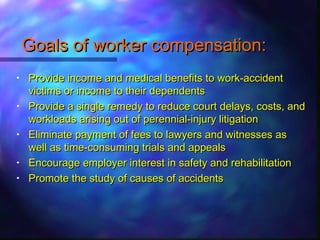

Accidents are caused by multiple interacting factors including human error, equipment failures, and environmental conditions. Major causes of workplace injuries in the US include overexertion, impacts, falls, and exposure to chemicals and extreme temperatures. Legislation like Workers' Compensation aims to provide benefits to injured workers while encouraging safety. Government agencies like OSHA and NIOSH were established to set and enforce safety standards in industries. Accidents result from interactions between human, job, equipment, and environmental factors.

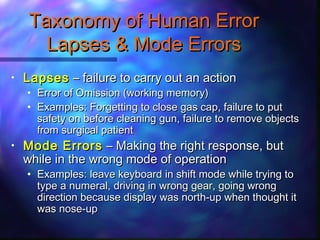

![Human Reliability AnalysisHuman Reliability Analysis

• Human Reliability AnalysisHuman Reliability Analysis –– predict reliability ofpredict reliability of

system in terms of probability of failure or mean timesystem in terms of probability of failure or mean time

between failures (MTBF) when system is designed tobetween failures (MTBF) when system is designed to

work in parallel or serieswork in parallel or series

.9 .9

.9

.9

SeriesSeries

ParallelParallel

Reliability = .9 x .9 = .81Reliability = .9 x .9 = .81

P(failure) = 1 - .81 = .19P(failure) = 1 - .81 = .19

Reliability = 1 – [(1 - .9) (1 - .9)]Reliability = 1 – [(1 - .9) (1 - .9)]

= 1 - .01 = .99= 1 - .01 = .99

P(failure) = 1 - .99 = .01P(failure) = 1 - .99 = .01(see homework)](https://image.slidesharecdn.com/hfchapter14-170508183937/85/Safety-Accidents-and-Human-Error-20-320.jpg)

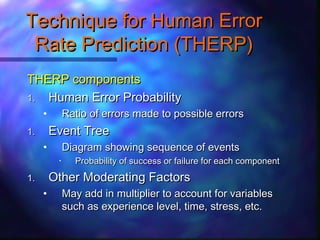

![THERP Event TreeTHERP Event Tree

aa AA

baba BaBa

SS

SS

bAbA BABA

FF

SS

FF

SS

FF

FF

SeriesSeries

ParallelParallel

Series:

P[S] = a(ba)

P[F] = 1 – a(ba) = a(Ba) + A(bA) + A(BA)

Parallel:

P[S] = 1 – A(BA) = a(ba) + a(Ba) + A(bA)

P[F] = A(BA)

P(successful task B given A)

P(unsuccessful task B given A)

P(success of task B given a)

P(Unsuccessful task B given a)

P(successful task A) P(unsuccessful task A)

Task A = first task

Task B = second task](https://image.slidesharecdn.com/hfchapter14-170508183937/85/Safety-Accidents-and-Human-Error-22-320.jpg)