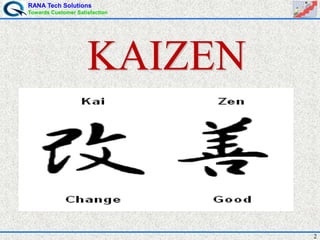

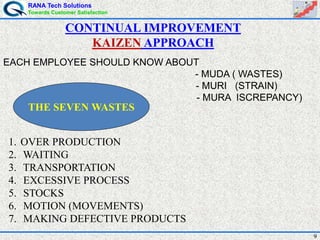

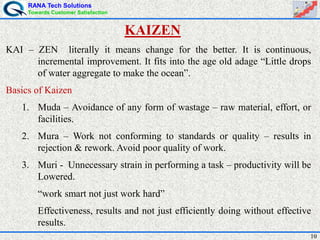

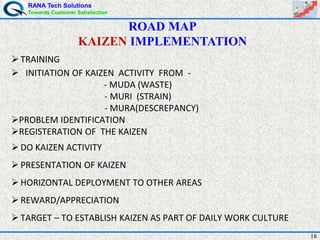

The document discusses the concept of Kaizen, which is a Japanese philosophy of continual improvement. It was introduced by Masaaki Imai and means "change for better". The document outlines the benefits of Kaizen such as identifying waste and improving skills. It describes the seven types of waste as overproduction, waiting, transportation, excess processing, inventory, unnecessary movement, and defects. Additionally, it provides examples of Kaizen and notes that the goal is to establish continual improvement as part of daily work culture.