1. Welding defects are discontinuities or irregularities in the weld that exceed code limits. Common defects include cracks, porosity, lack of fusion, undercut, and inclusions.

2. Defects can be caused by incorrect welding parameters, procedures, conditions, material selection, welder skill, or preparations.

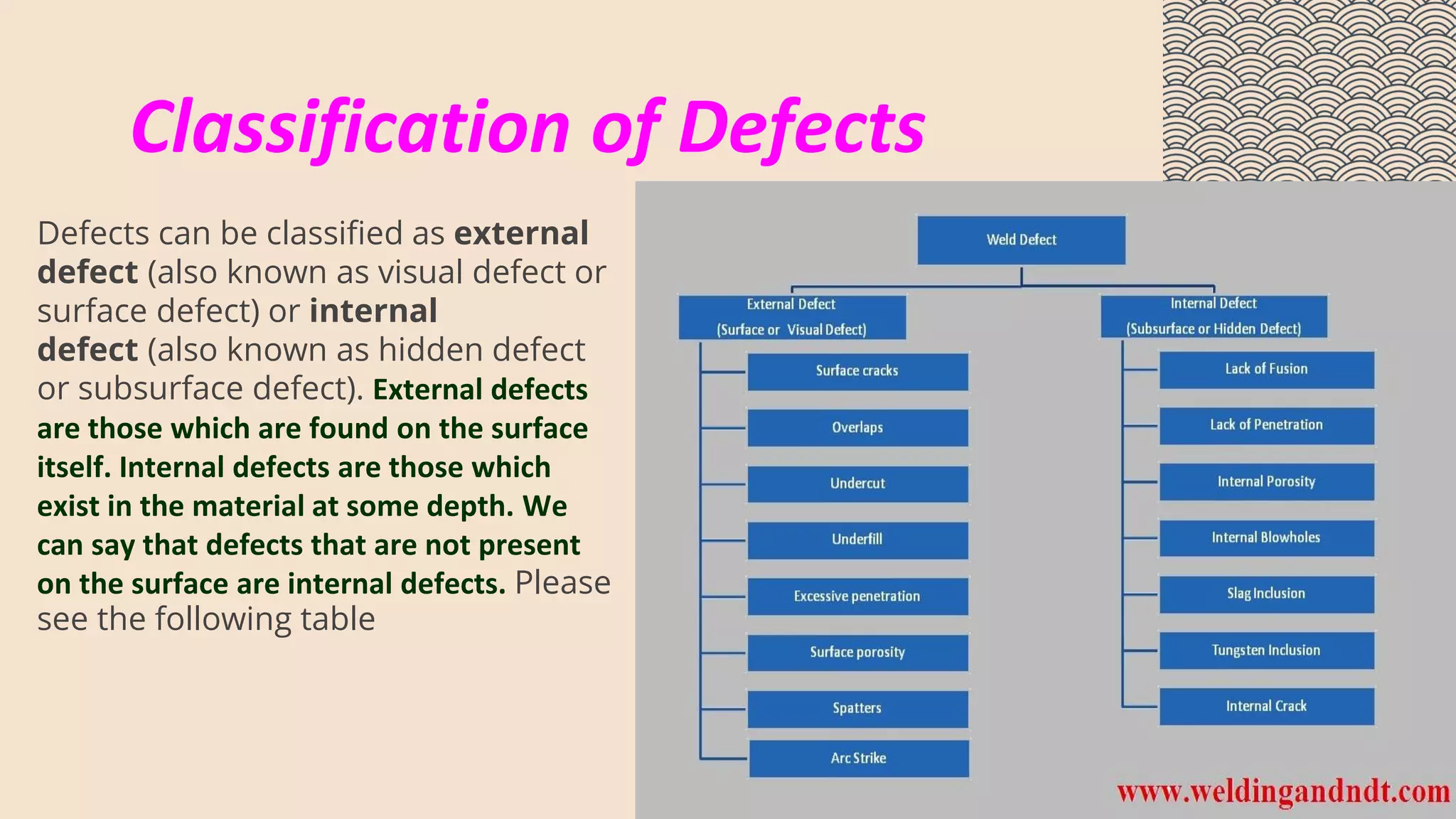

3. Defects are classified as external/visual or internal/hidden. External defects are on the surface while internal defects exist below the surface.