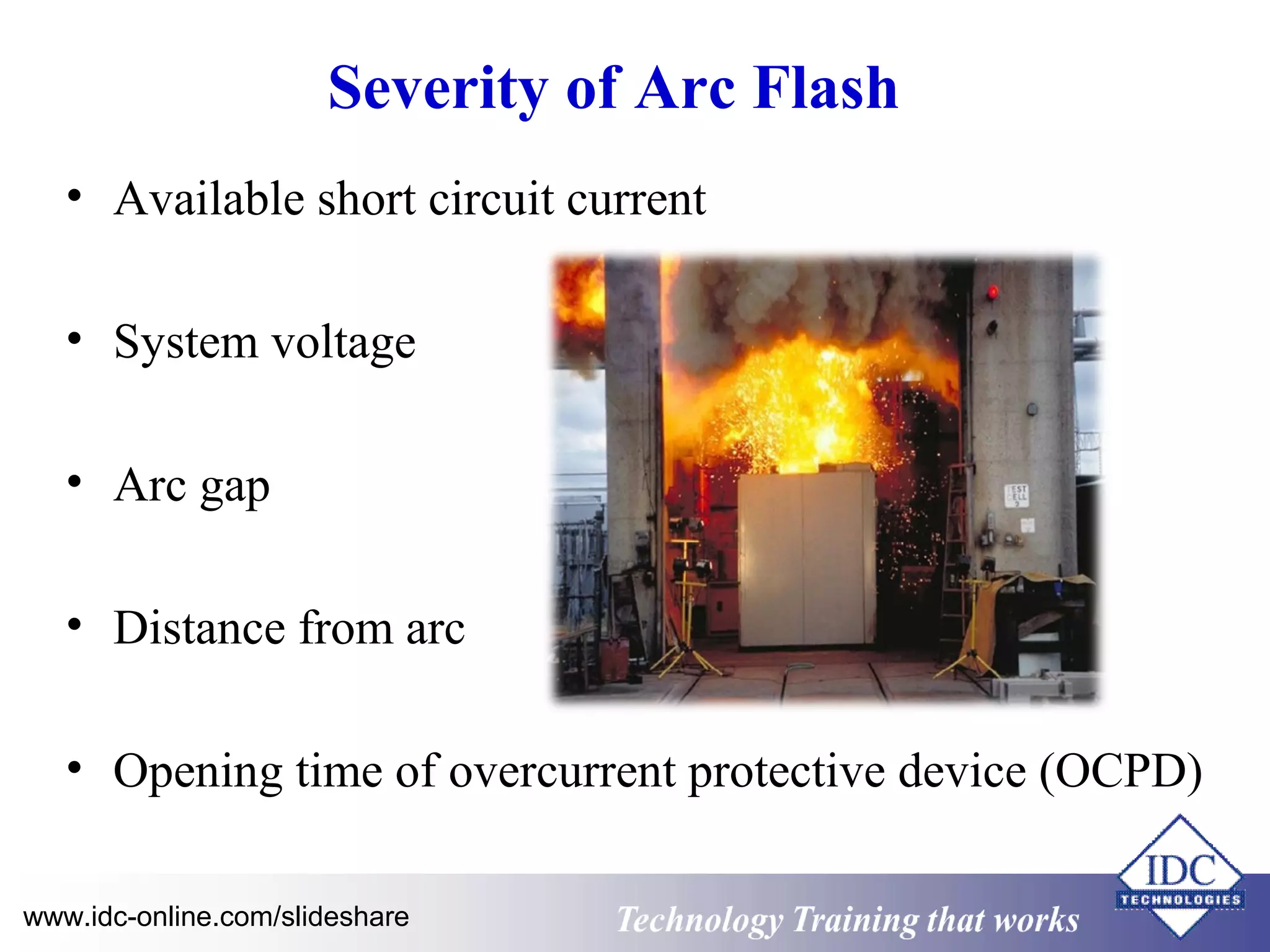

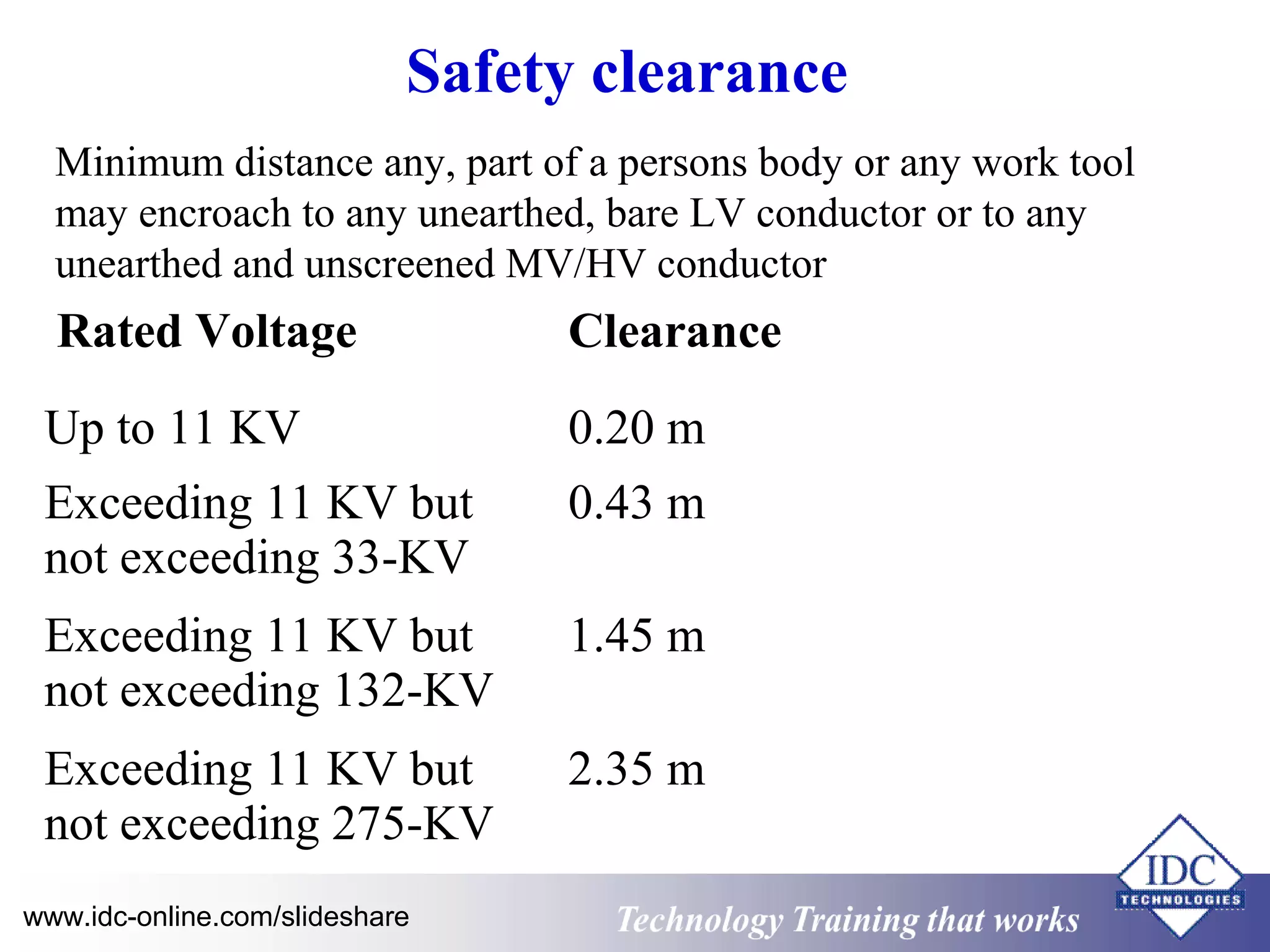

The document outlines high voltage safety operating procedures for engineers and technicians, detailing voltage classifications, the life-threatening effects of electrical current, and various hazards associated with electrical equipment. It emphasizes the necessity of personal protective equipment, safe maintenance practices, and calculations for arc-flash hazards as critical to ensuring worker safety. Additionally, it discusses different insulation types, electrical accident causes, and general safety measures to mitigate risks in electrical environments.