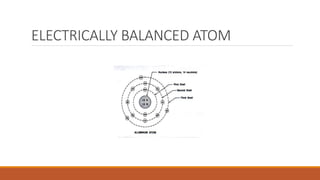

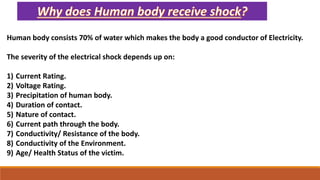

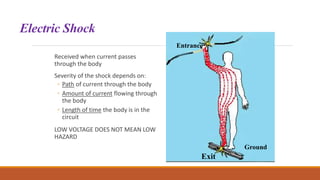

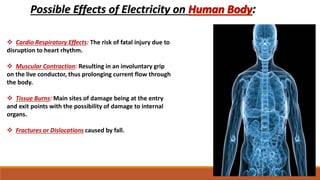

1) Electrical safety involves understanding atoms, electrons, and how electricity is generated through magnetism. Proper safety practices are needed to prevent electrical shock and burns.

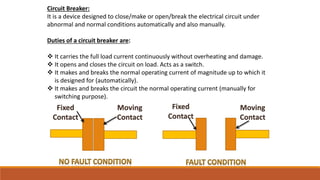

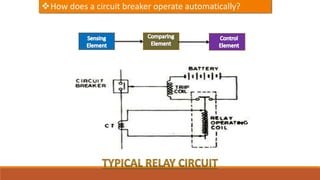

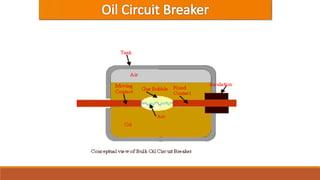

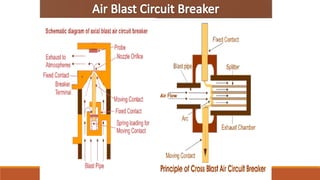

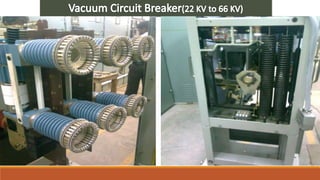

2) Circuit breakers automatically open electrical circuits under abnormal or normal conditions to prevent overloading. They carry full load currents and can manually or automatically make or break operating currents.

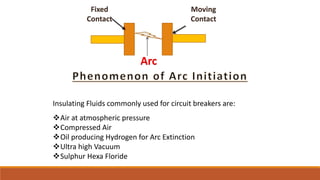

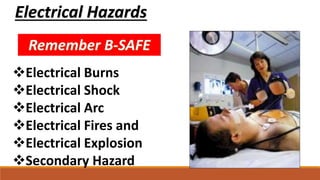

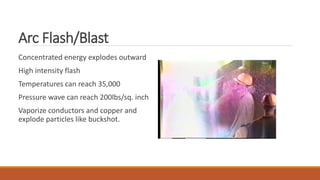

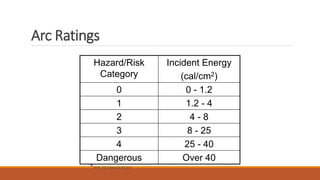

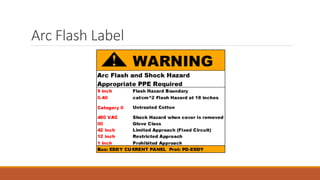

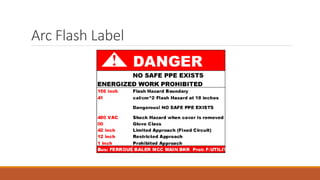

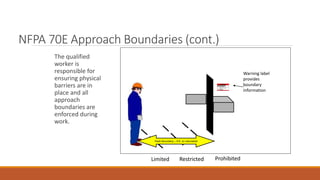

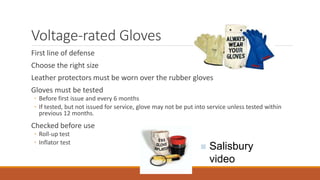

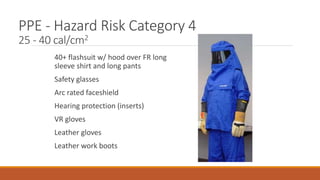

3) Arc flash occurs when electricity arcs from one conductor to another or ground, producing intense heat and pressure that can severely burn or injure a person. Proper personal protective equipment and safety procedures are required when working on energized equipment.