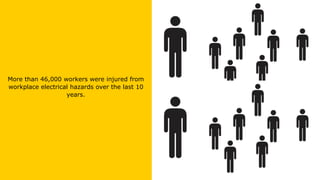

The document discusses workplace electrical safety, highlighting the significant risks and statistics surrounding electrical hazards, which result in over 300 deaths and 4,000 injuries annually in the U.S. It emphasizes the importance of safety awareness, proper equipment, and maintenance, along with adherence to safety standards such as NFPA 70E and OSHA regulations to mitigate these hazards. Current Solutions PC offers a comprehensive training program to educate employees on electrical safety practices.