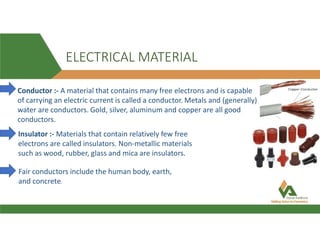

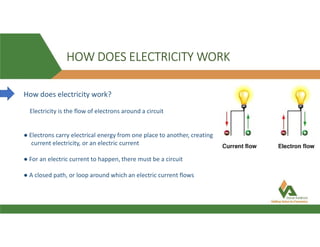

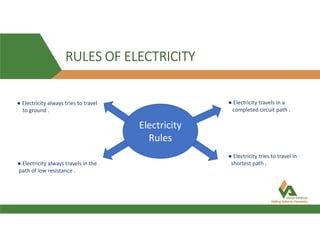

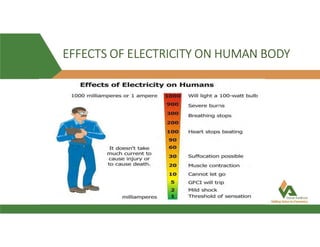

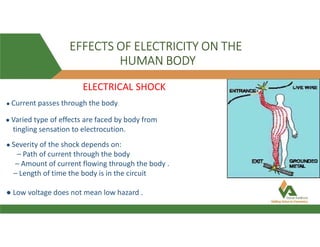

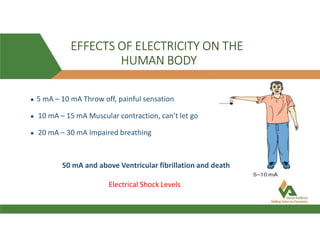

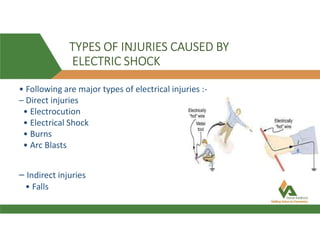

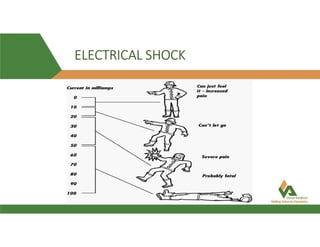

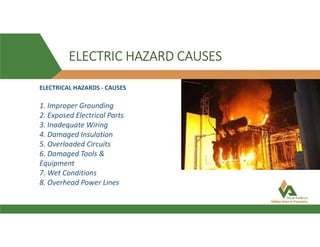

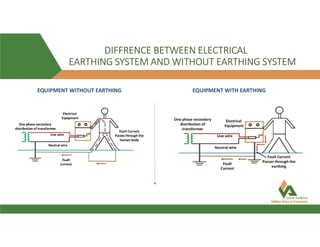

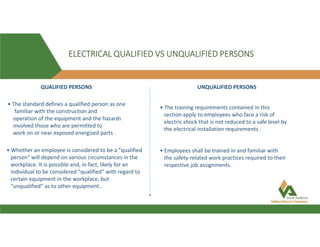

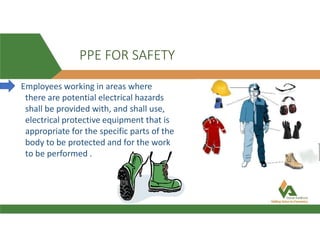

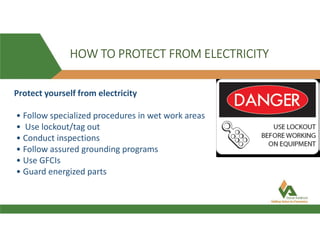

The document discusses electrical safety. It defines electricity and its forms, electrical materials like conductors and insulators, and how electricity works by flowing through circuits. It describes the effects of electricity on the human body like electrical shocks and injuries. It emphasizes the importance of electrical safety and outlines safety practices like using personal protective equipment, lockout/tagout procedures, inspections, grounding, and being qualified for different electrical work. The document provides guidelines for working safely around electricity.