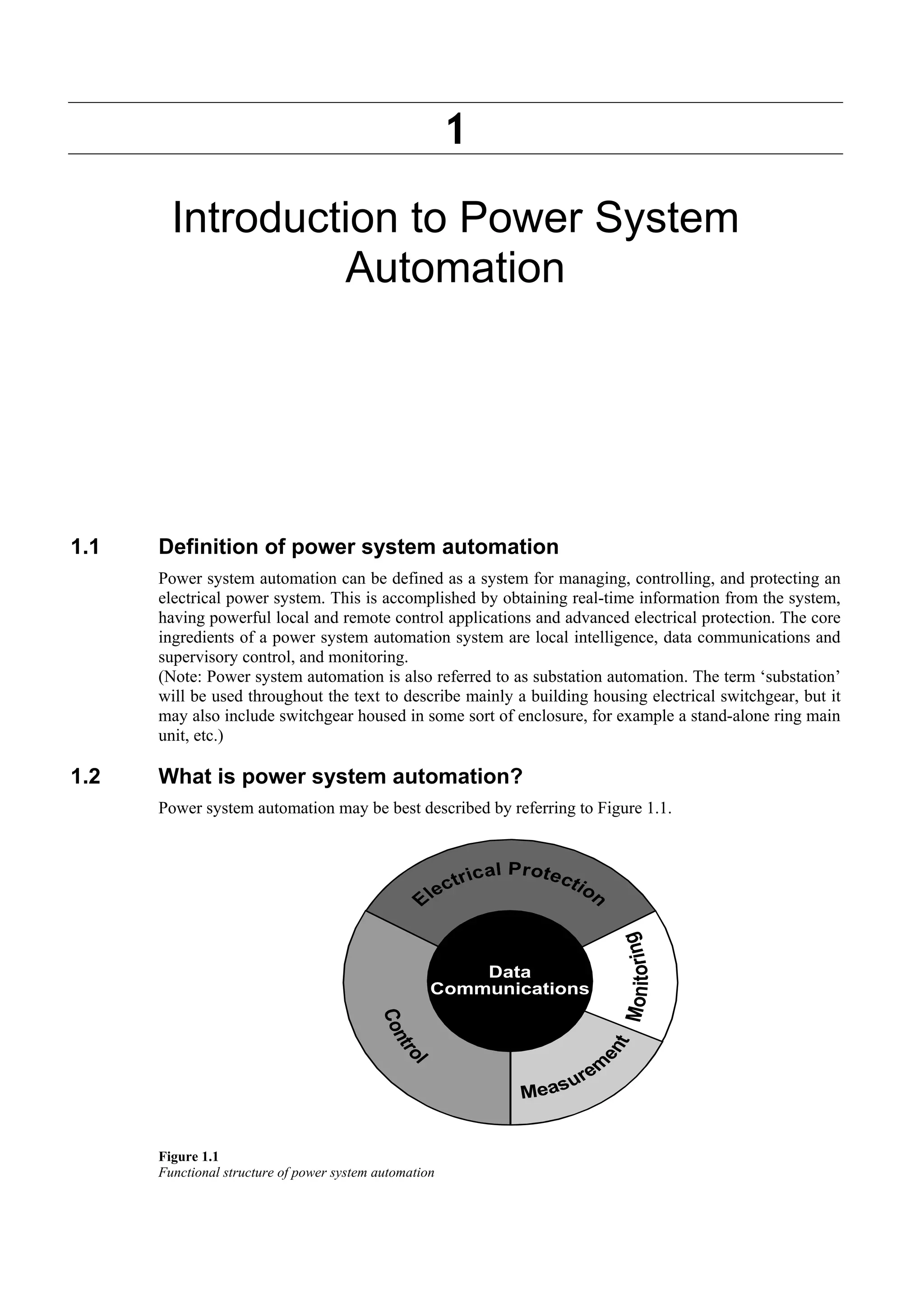

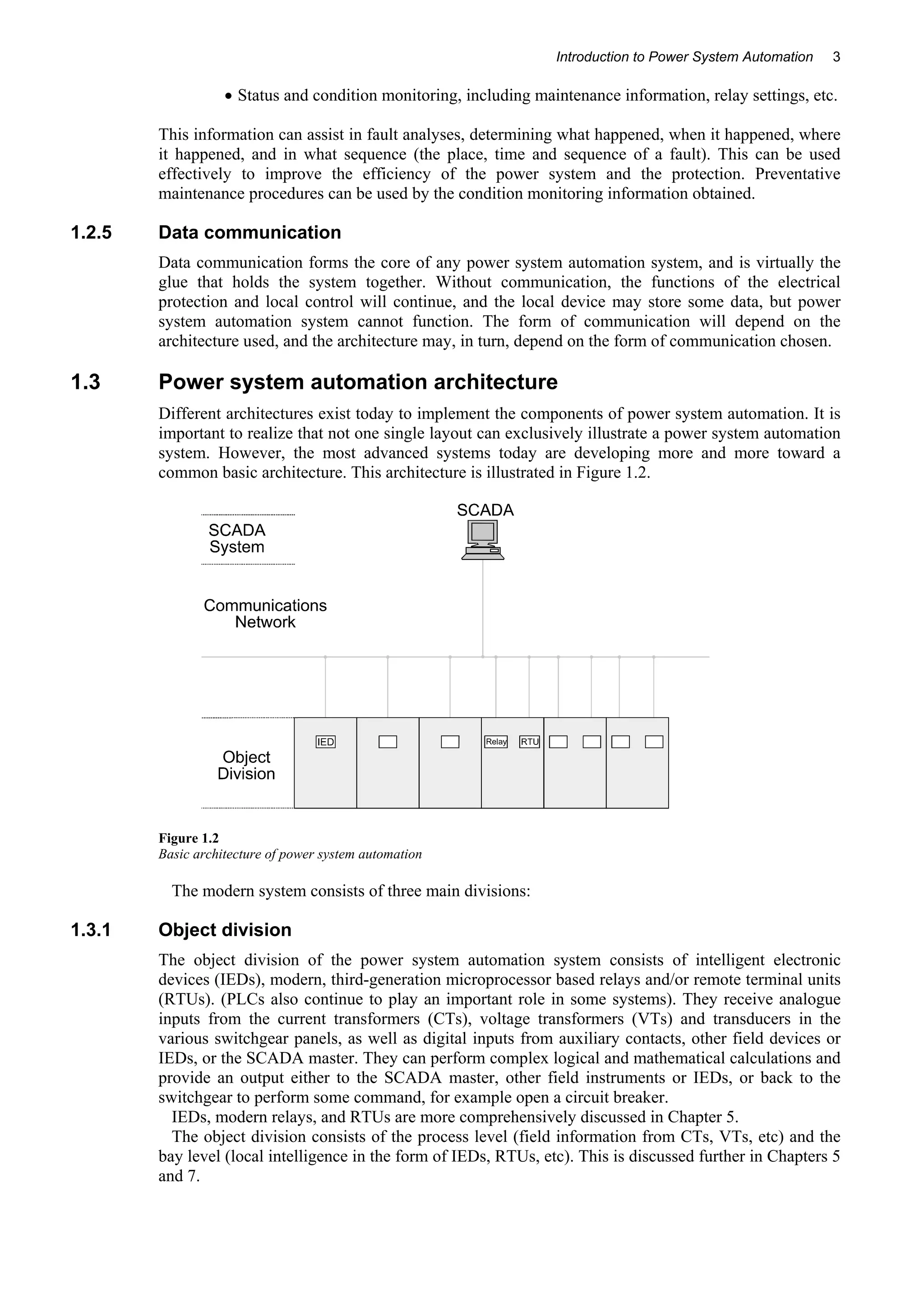

This document provides an introduction to power system automation. It defines power system automation as a system for managing, controlling, and protecting an electrical power system using real-time information, control applications, and electrical protection. The core components of power system automation are described as local intelligence, data communications, supervisory control and monitoring. The document outlines the basic architecture of power system automation which includes the object division comprising intelligent electronic devices and remote terminal units, the communications network, and the SCADA master station which receives data and issues commands.