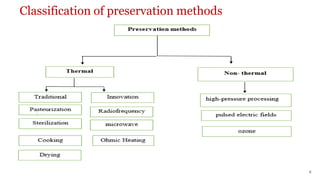

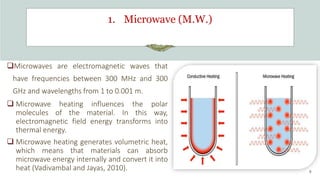

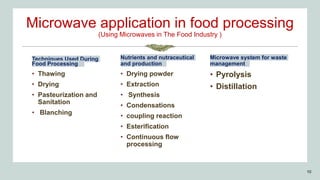

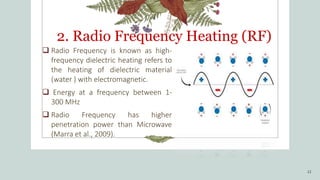

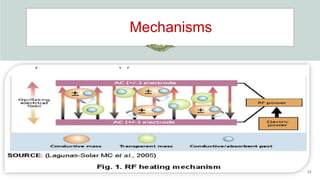

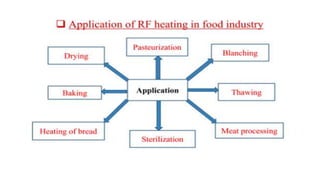

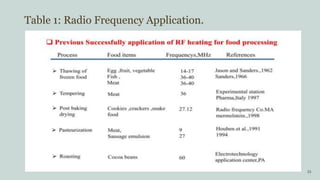

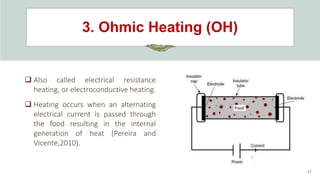

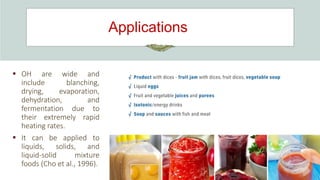

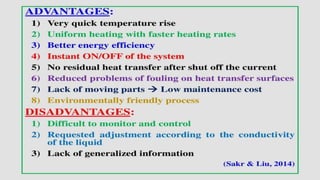

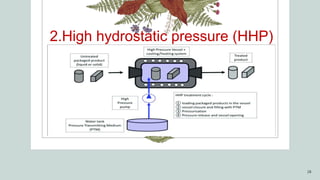

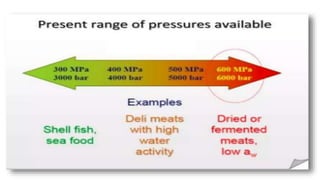

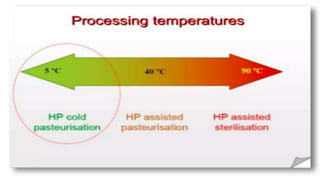

1) The document discusses green preservation methods in food processing, including novel thermal technologies like microwave heating, radio frequency heating, and ohmic heating as well as non-thermal technologies like pulsed electric fields, high hydrostatic pressure, and ozone treatment.

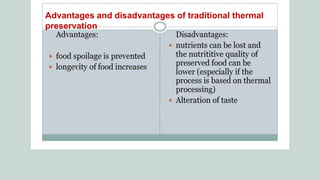

2) It aims to compare traditional thermal food processing which can degrade quality to novel technologies that can improve quality.

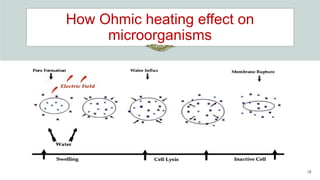

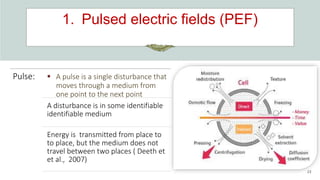

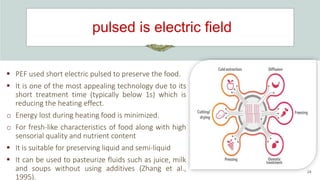

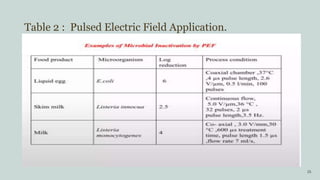

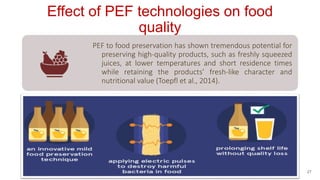

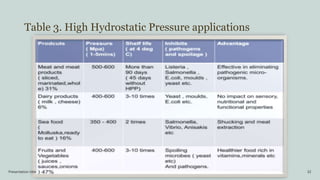

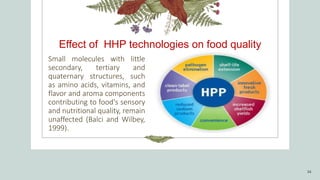

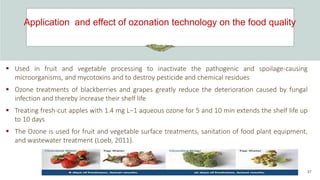

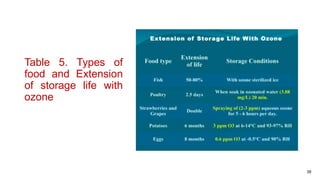

3) Novel technologies like pulsed electric fields, high pressure processing, and ozone are presented as alternatives to heat that can inactivate microbes while better retaining nutrients, sensory properties, and shelf life of foods.