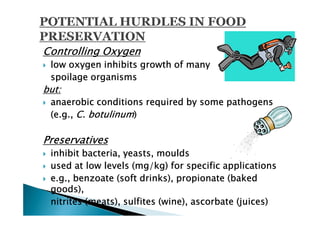

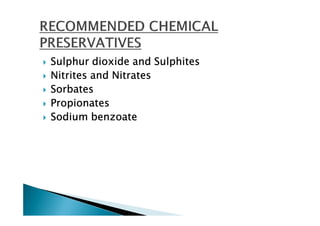

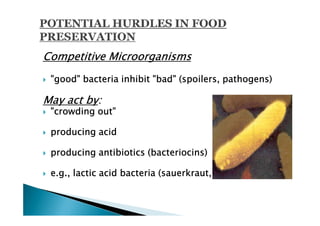

Hurdle technology uses a combination of preservation methods to make foods shelf-stable while maintaining quality and safety. It involves using multiple hurdles like reduced moisture, increased acidity, refrigeration, or addition of preservatives that microorganisms must overcome to grow. The hurdles work synergistically so that microbes cannot adapt to or overcome all of the preservation factors simultaneously. This allows foods to be processed more gently and minimally while still achieving a long shelf life.