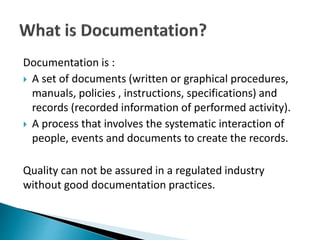

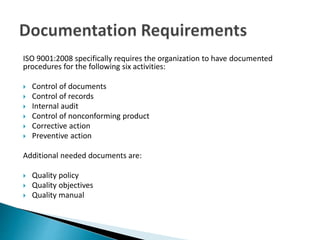

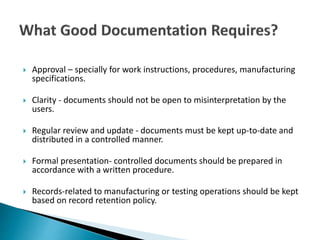

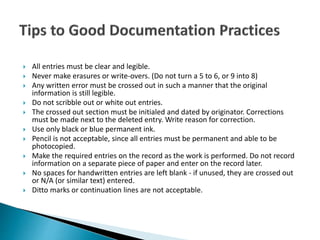

The document outlines ISO 9000:2005 guidelines on quality management systems, emphasizing the importance of effective documentation, which includes various formats and must be clear and legible. It specifies required documented procedures for key activities like document control and corrective actions, and mandates regular review and updates of documents. Additionally, it provides detailed instructions on how to maintain records, correction practices, and the proper mediums for documentation.