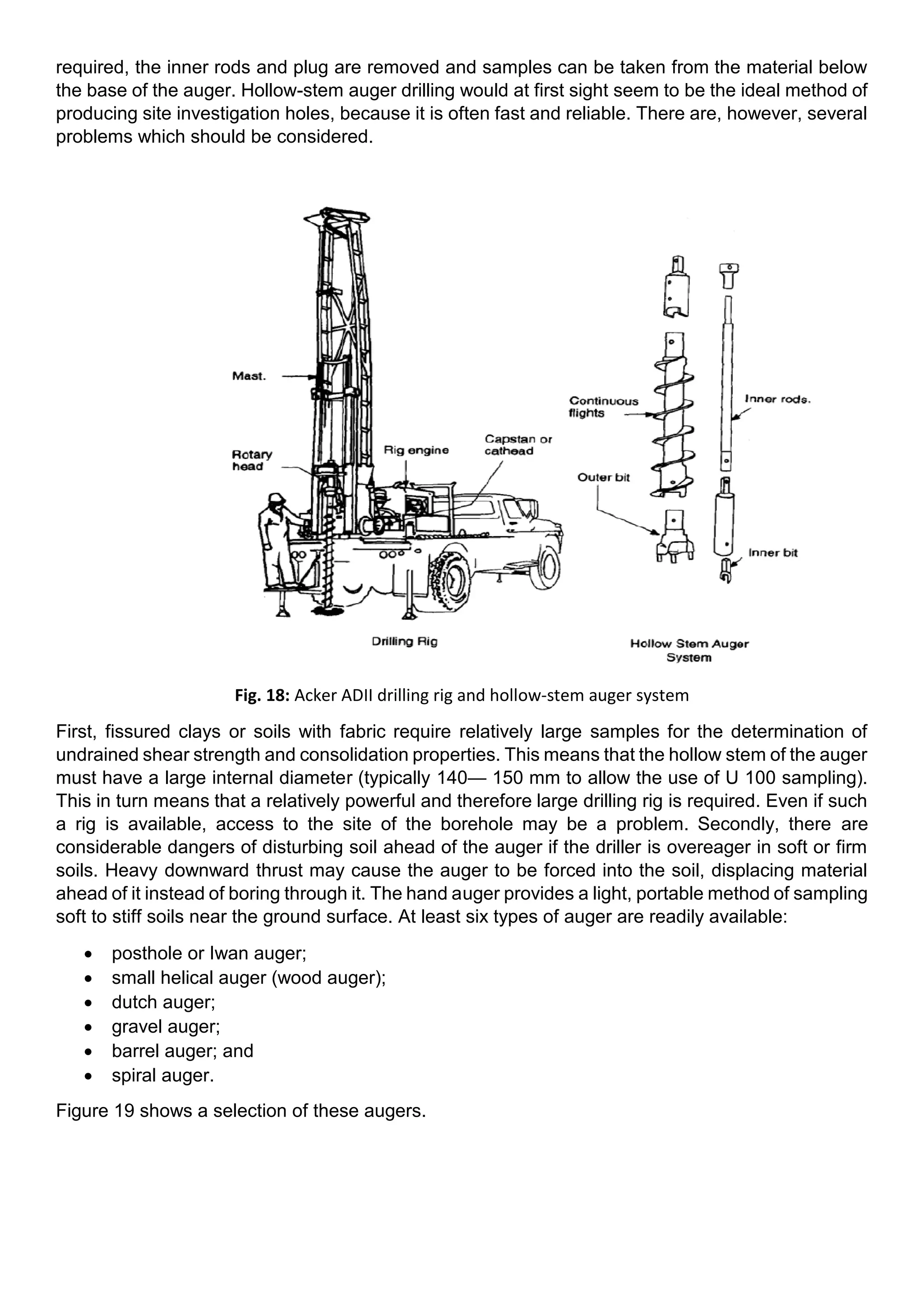

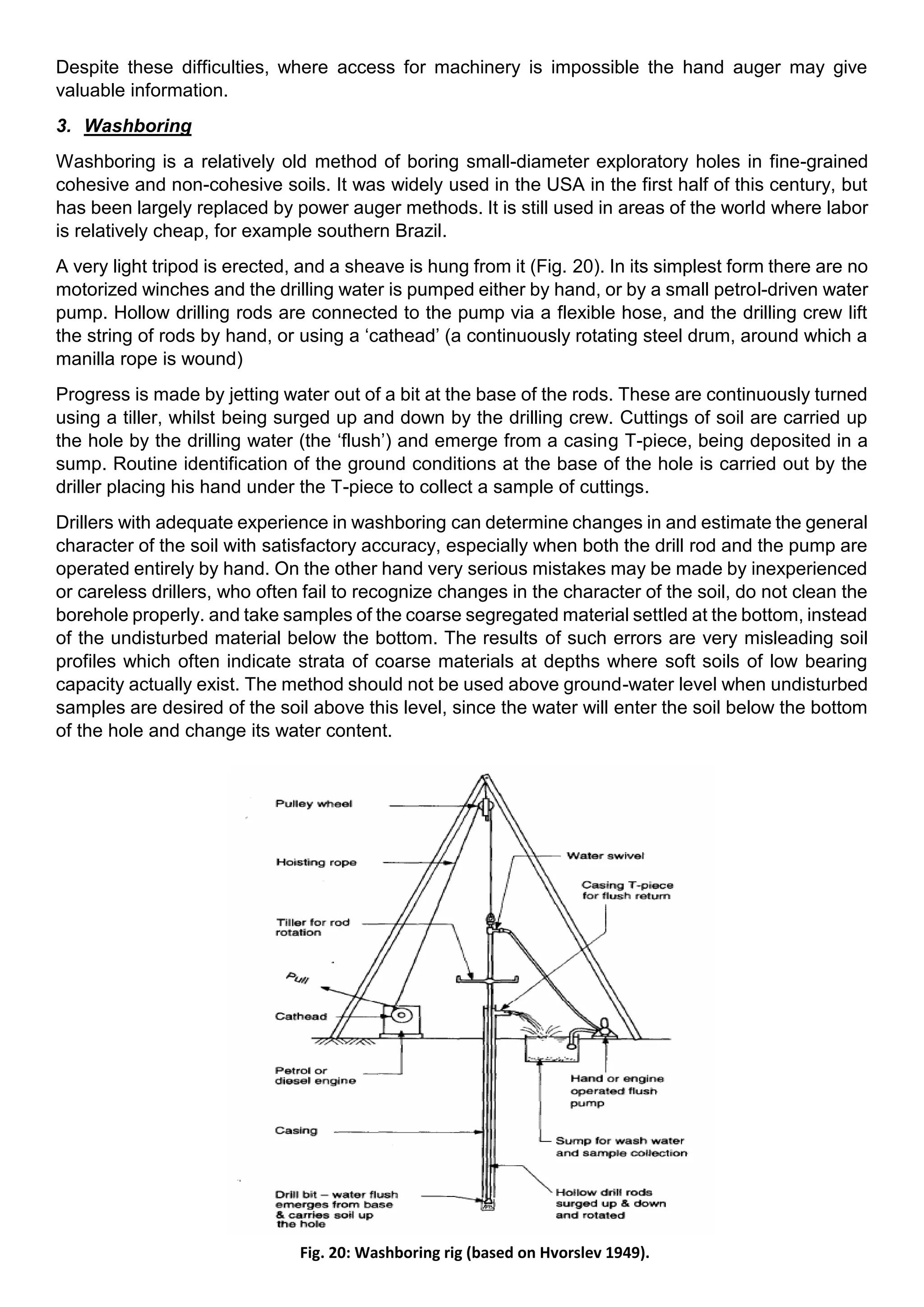

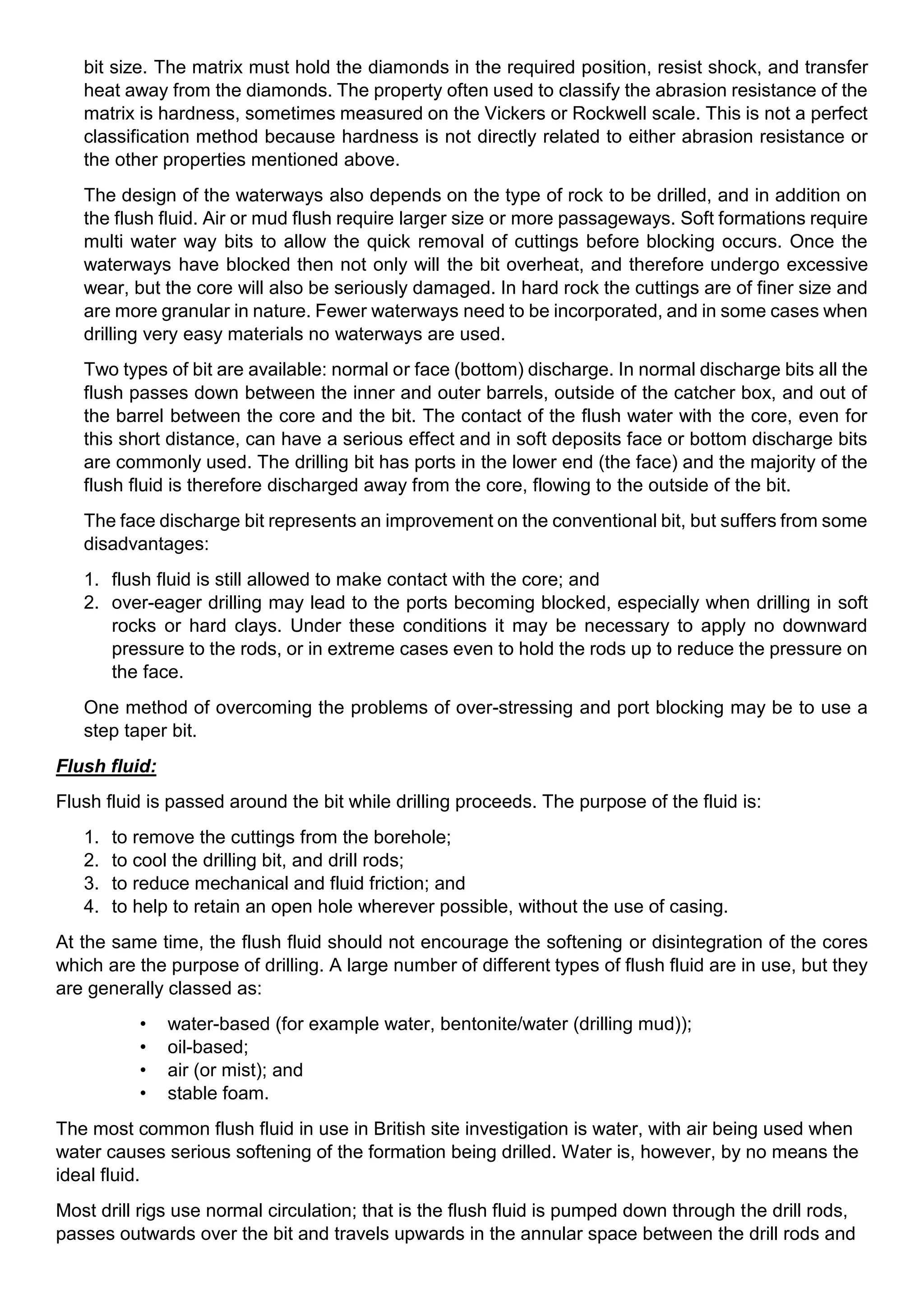

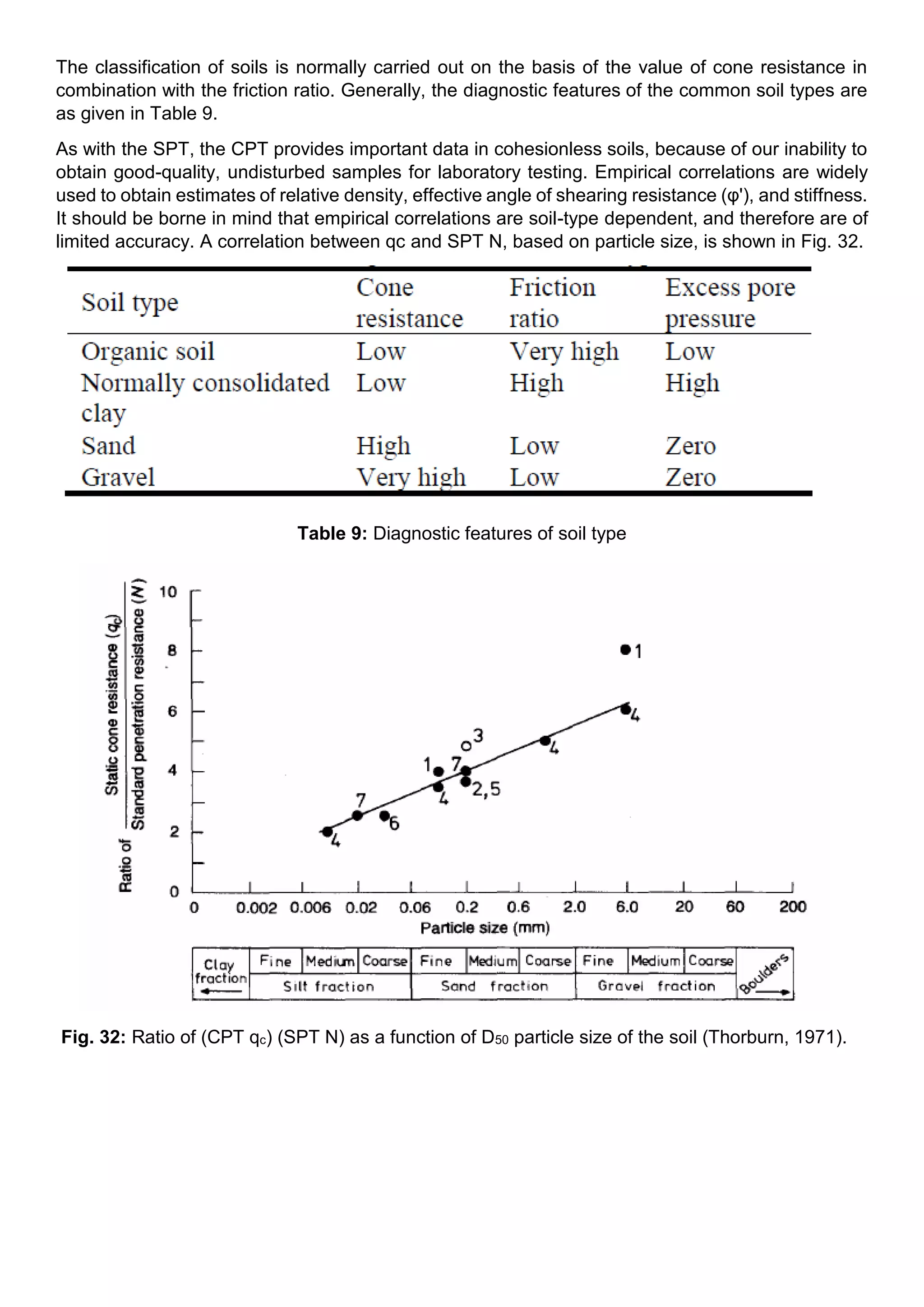

This document provides an overview of geotechnical site investigation. It discusses the history and development of site investigations, different approaches to site investigations from desk studies to limited investigations with monitoring, and the typical sequence of a geotechnical site investigation. It also describes various subsurface exploration techniques including geophysics, boring, drilling, probing, and in situ testing methods.

![1874). During the industrial period preceding the twentieth century, many of the currently used

geotechnical processes for the improvement of ground, such as piling, pre-loading, compaction and

de-watering appear to have been used. These techniques were applied in a purely empirical

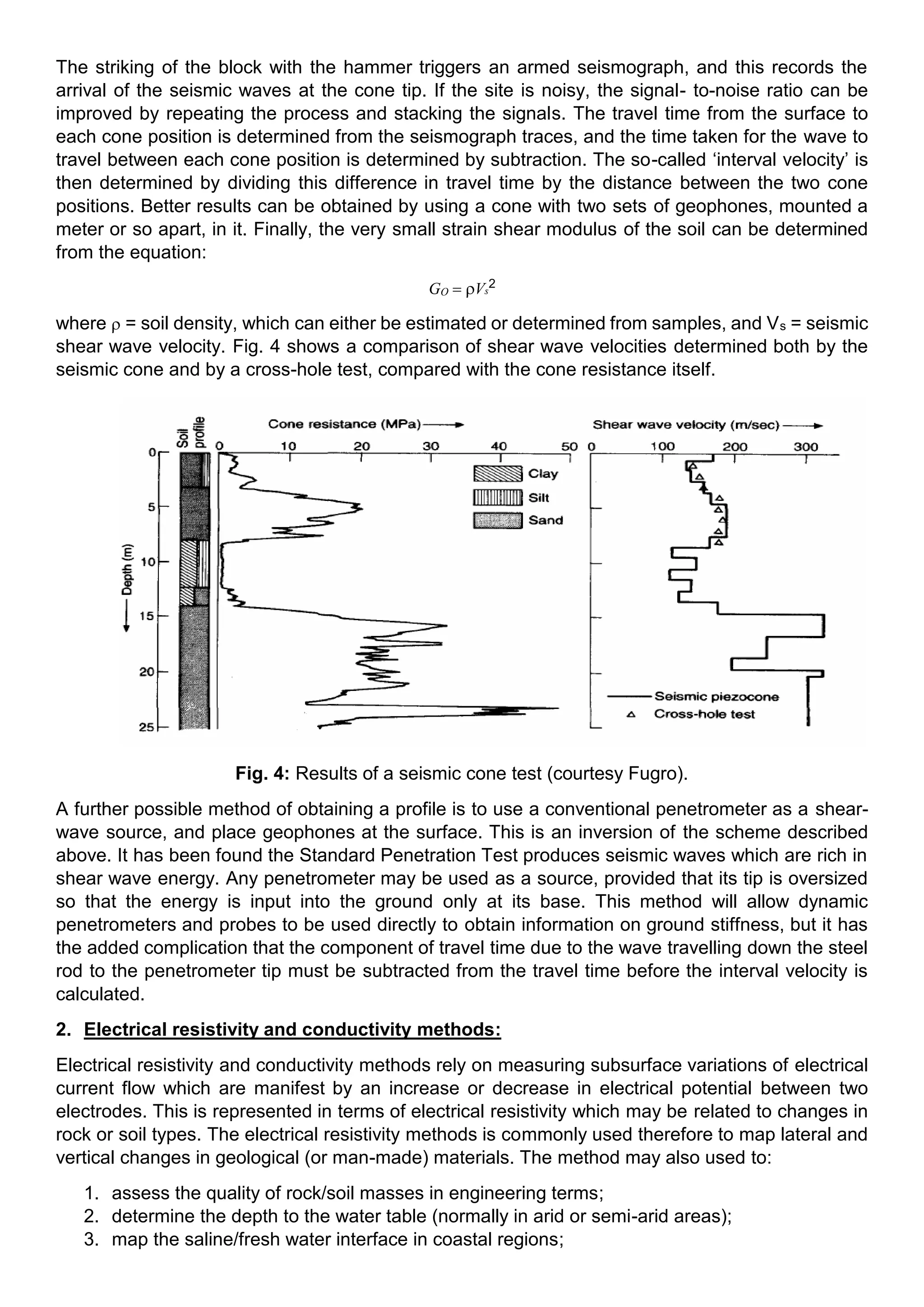

manner.

At the turn of the twentieth century, a series of major failures occurred which led to the almost

simultaneous formation of geotechnical research groups in various countries. In America, slope

failures on the Panama Canal led to the formation of the American Foundations Committee of the

American Society of Civil Engineers in 1913 and, in Sweden, landslides during a railway construction

resulted in the formation of the State Geotechnical Commission in the same year. Following a

number of embankment and dyke failures, a government committee under Buisman was set up in

Holland in 1920. Casagrande (1960), however, dates the advent of modern soil mechanics to the

period between 1921 and 1925, when Terzaghi published several important papers relating to the

pore pressures set up in clay during loading, and their dissipation during consolidation,

Terzaghi’s first professional work in England was in 1939, when he was retained to investigate a

slope failure at the Chingford reservoir. As a result, the first commercial soil mechanics laboratory

in the UK was established by John Mowlem and became Soil Mechanics Ltd in 1943 .Whyte (1976)

reports that by 1948 five other contractors and one consultant had soils divisions.

Major encouragement was given to soils research in the UK by Cooling, who influenced a number

of engineers (for example Skempton, Bishop and Golder) who worked at the Building Research

Station in the 1940s. In 1948, Géotechnique commenced publication, and by 1955 a great number

of significant papers on soil mechanics had been published covering topics such as site

investigation, seepage, slope stability and settlement.

According to Mayniel (1808), Bullet was the first to try to establish an earth pressure theory, in 1691.

More importantly from our point of view, Bullet notes the importance of site investigation for the

foundations of earth-retaining structures and recommends the use of trial holes in order to determine

the different beds of soil beneath a site, and in order to ensure that poor soil does not underlie good

soil. Where trial holes could not be made, Bullet recommended the use of an indirect method of

investigation whereby the quality of the soil was determined from the sound and penetration

achieved when it was beaten with a 6—8 ft length of rafter.

In 1949, the first draft Civil Engineering Code of Practice for Site Investigations was issued for

comment. At that time Harding (1949) delivered a paper to the Works Construction Division of the

Institution of Civil Engineers in which he detailed the methods of boring and sampling then available.

The recommendations made in that paper, and in discussions on the paper by Skempton, Toms

and Rodin form the basis of the majority of techniques still in use in site investigation in the United

Kingdom. For example, in his discussion on methods of boring, Harding notes that:

• the boring equipment used in site investigations is criticized by some who have not been

exposed to the need to carry it themselves, as being primitive and lacking in mechanization.

Whilst it is possible to think of many ingenious contrivances for removing articles at depths

below ground, in practice simple methods usually prove to be more reliable.

while Skempton confirmed this view:

• with that simple equipment [shell and auger gear and 102 mm dia. sampler] the majority of

site investigations in soils could be carried out and, moreover, sufficient experience was now

available to enable the positive statement to be made that, in most cases, the results obtained

by that technique (in association with laboratory tests) were sufficiently reliable for practical

engineering purposes.](https://image.slidesharecdn.com/secu8malrecaggxqyd86-signature-4919c84213c11aeee0141dd068118dd789c63b2916bf57ecc90b1e674a03b6e9-poli-180617231449/75/Geotechnical-site-investigation-6-2048.jpg)