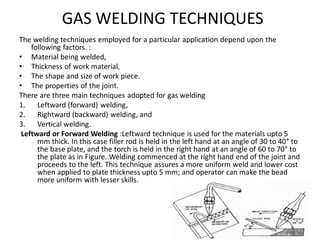

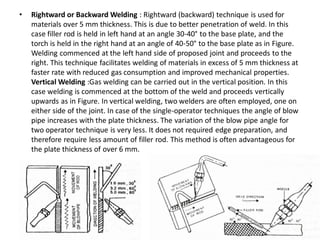

This document provides information on welding positions, gas welding and cutting, oxy-acetylene welding equipment and techniques. It discusses the different welding positions - flat, horizontal, vertical and overhead. It describes the oxy-acetylene welding process and equipment used, including cylinders, regulators, torches and flames. It also covers gas welding techniques such as leftward, rightward and vertical welding.