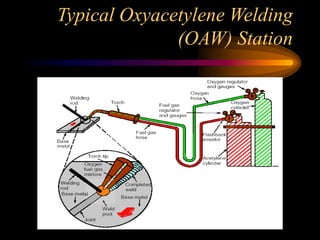

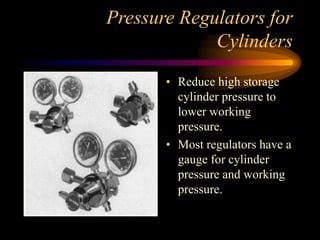

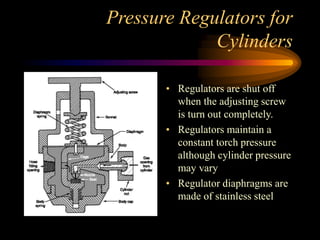

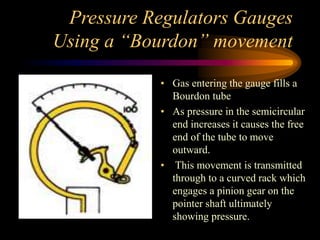

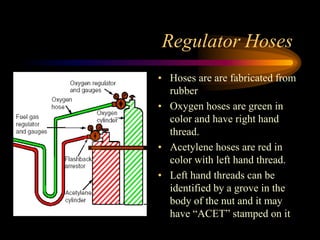

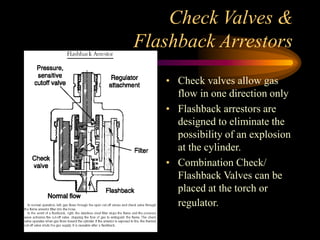

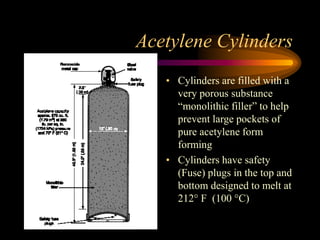

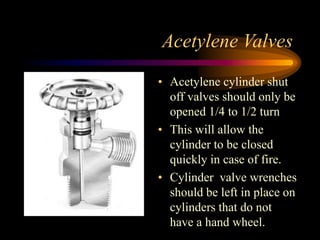

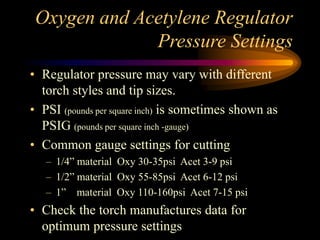

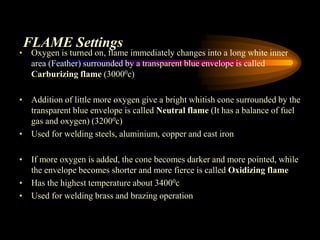

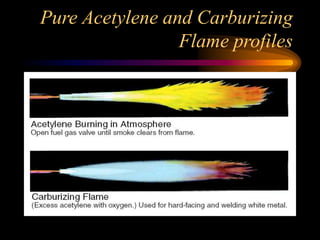

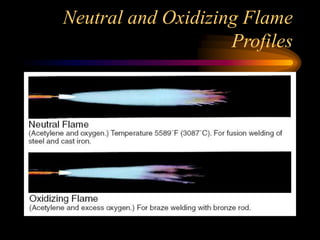

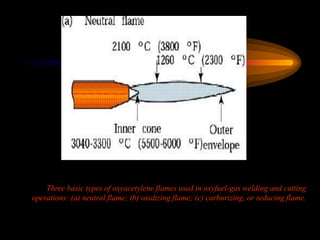

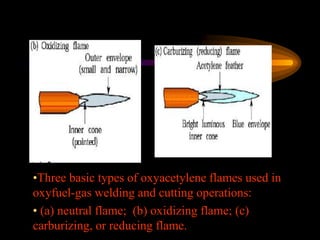

This document discusses oxyacetylene welding (OAW). OAW uses oxygen and acetylene gases to produce a high temperature flame for welding. The equipment needed includes oxygen and acetylene gas cylinders, pressure regulators to reduce the gas pressures, hoses to carry the gases to the torch, and check valves and flashback arrestors for safety. There are three types of oxyacetylene flames - neutral, oxidizing, and carburizing - which are produced by adjusting the ratio of oxygen to acetylene. The document provides details on setting up and using the equipment safely and properly for OAW.