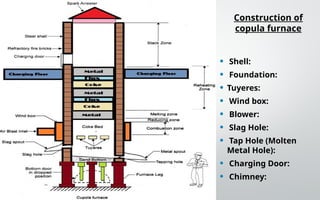

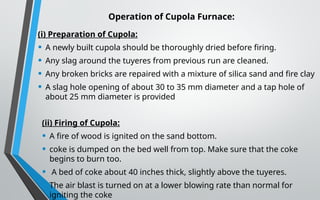

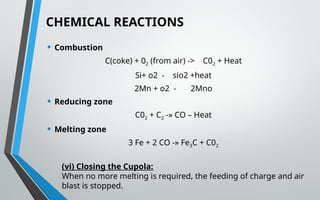

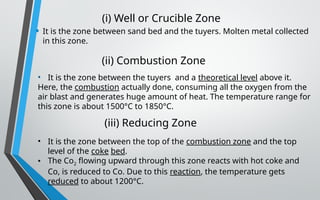

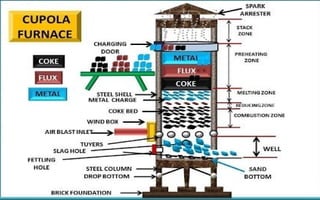

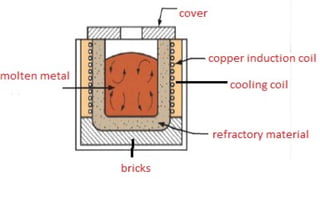

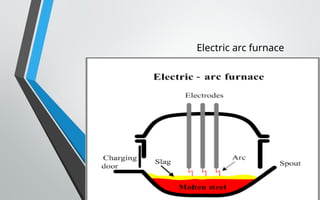

This document provides an overview of various types of furnaces used for high-temperature heating, including cupola, induction, and electric arc furnaces. It discusses their construction, operation, advantages, and limitations, emphasizing the principles behind each furnace type and their applications in melting metals. The document outlines specific processes such as charging, melting, and temperature control, as well as chemical reactions that occur during operation.