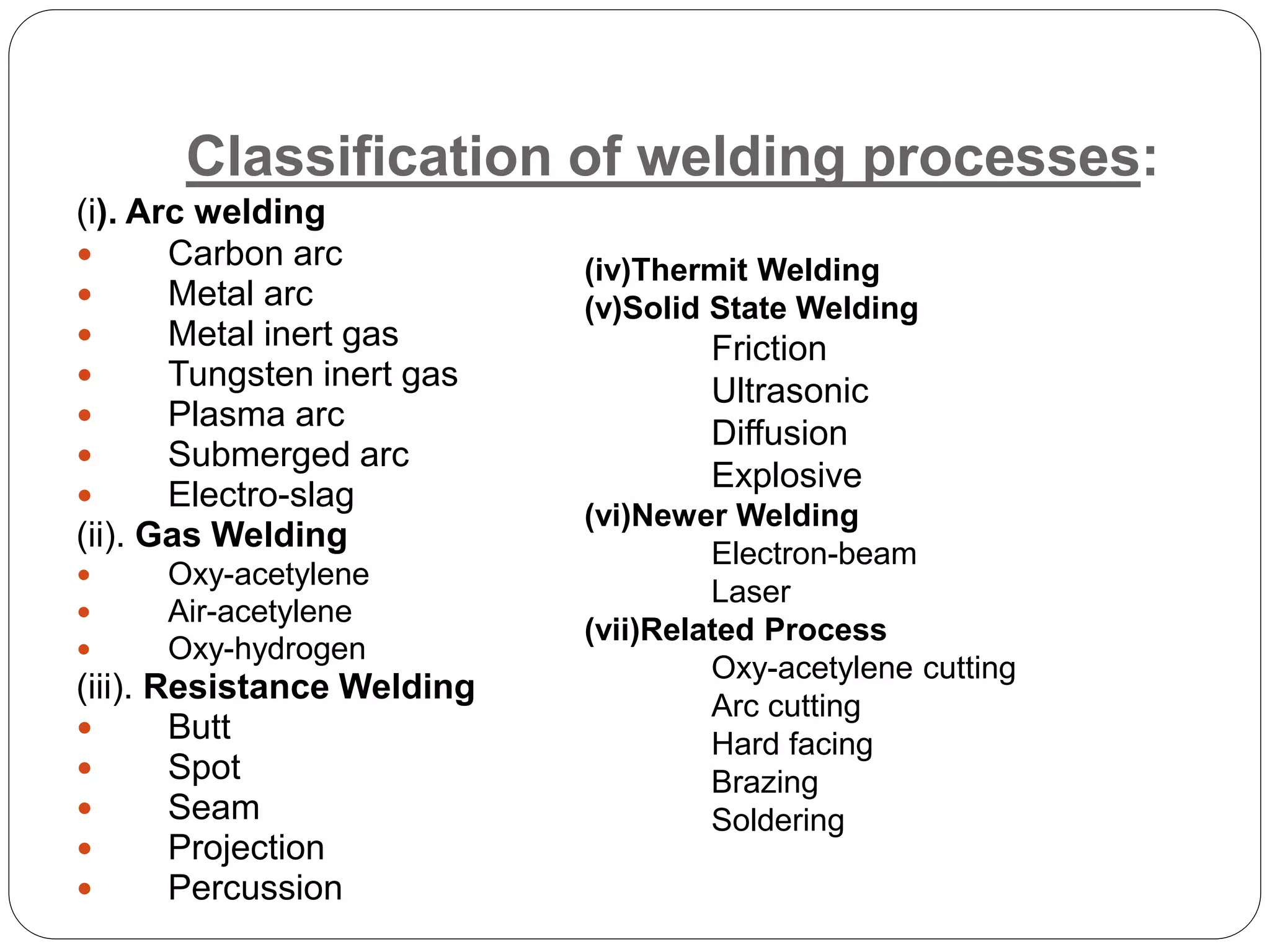

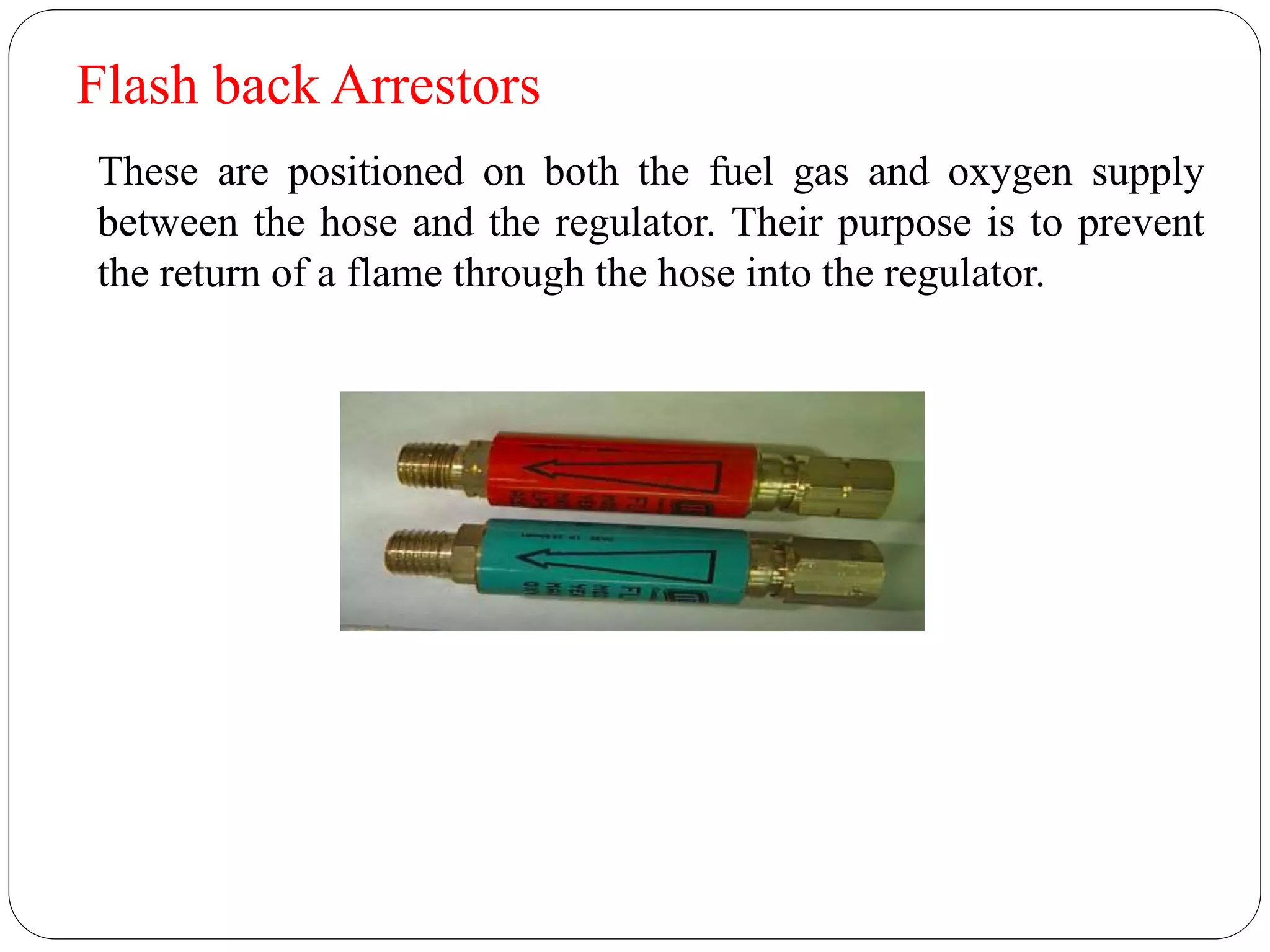

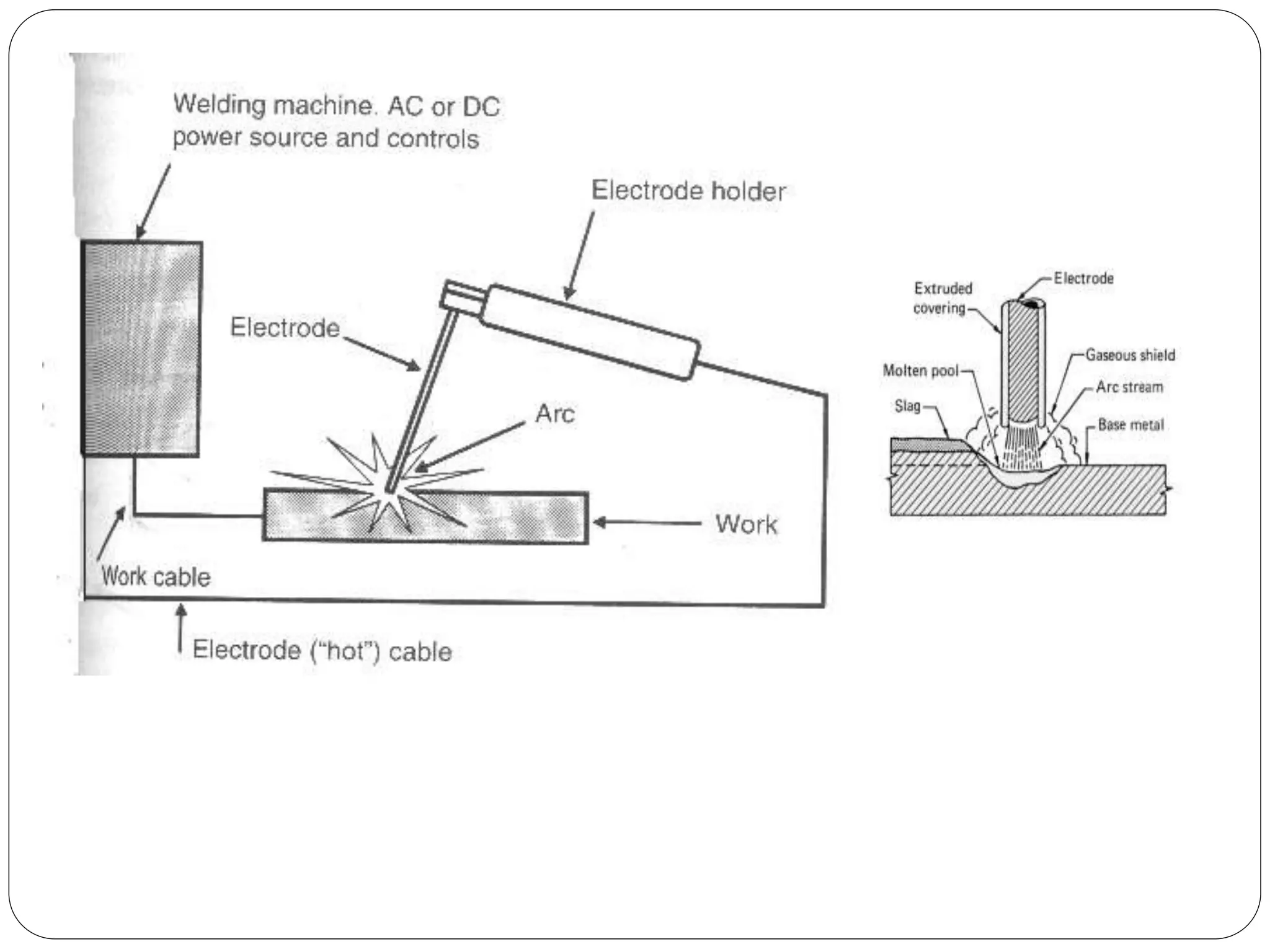

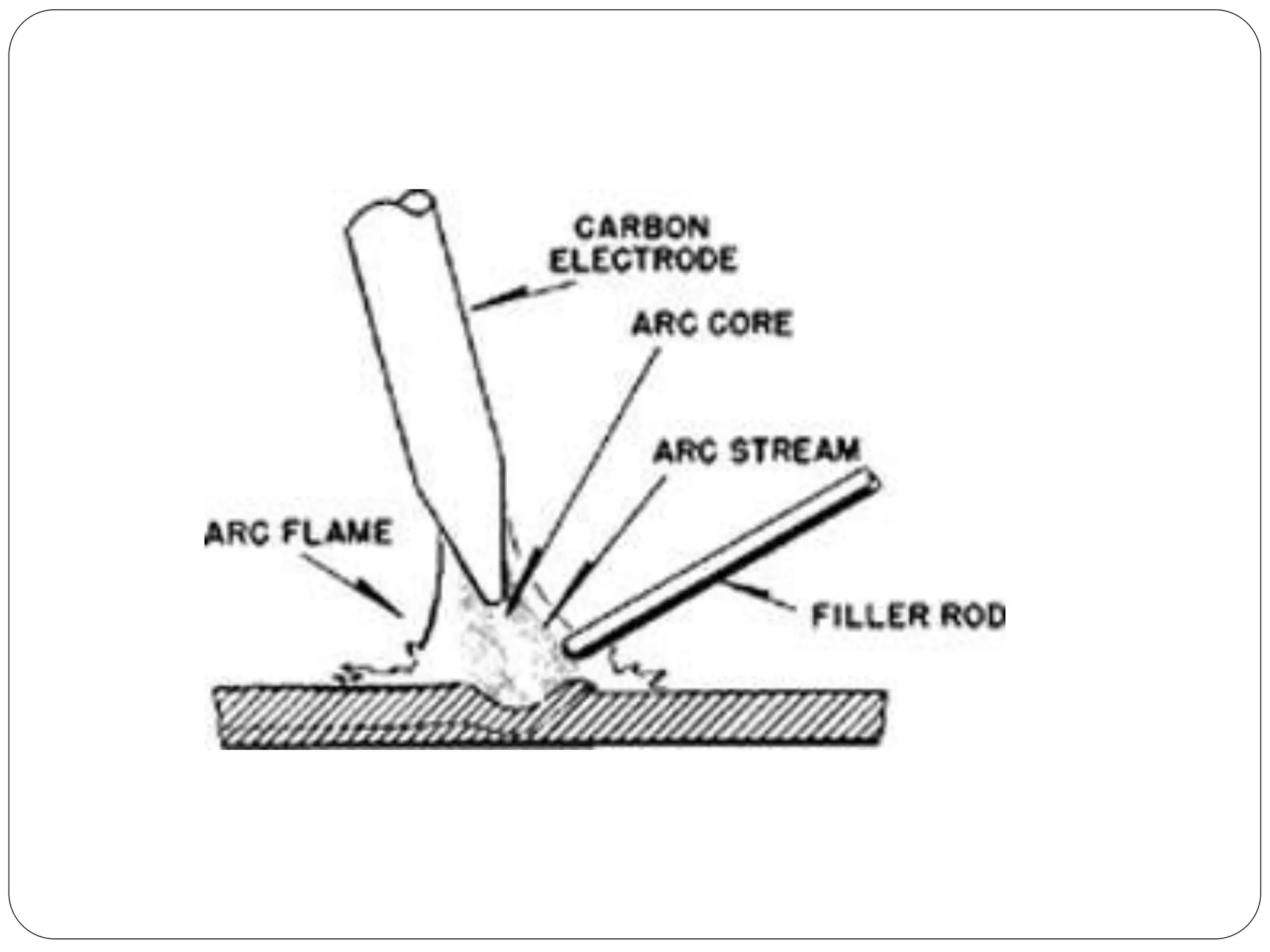

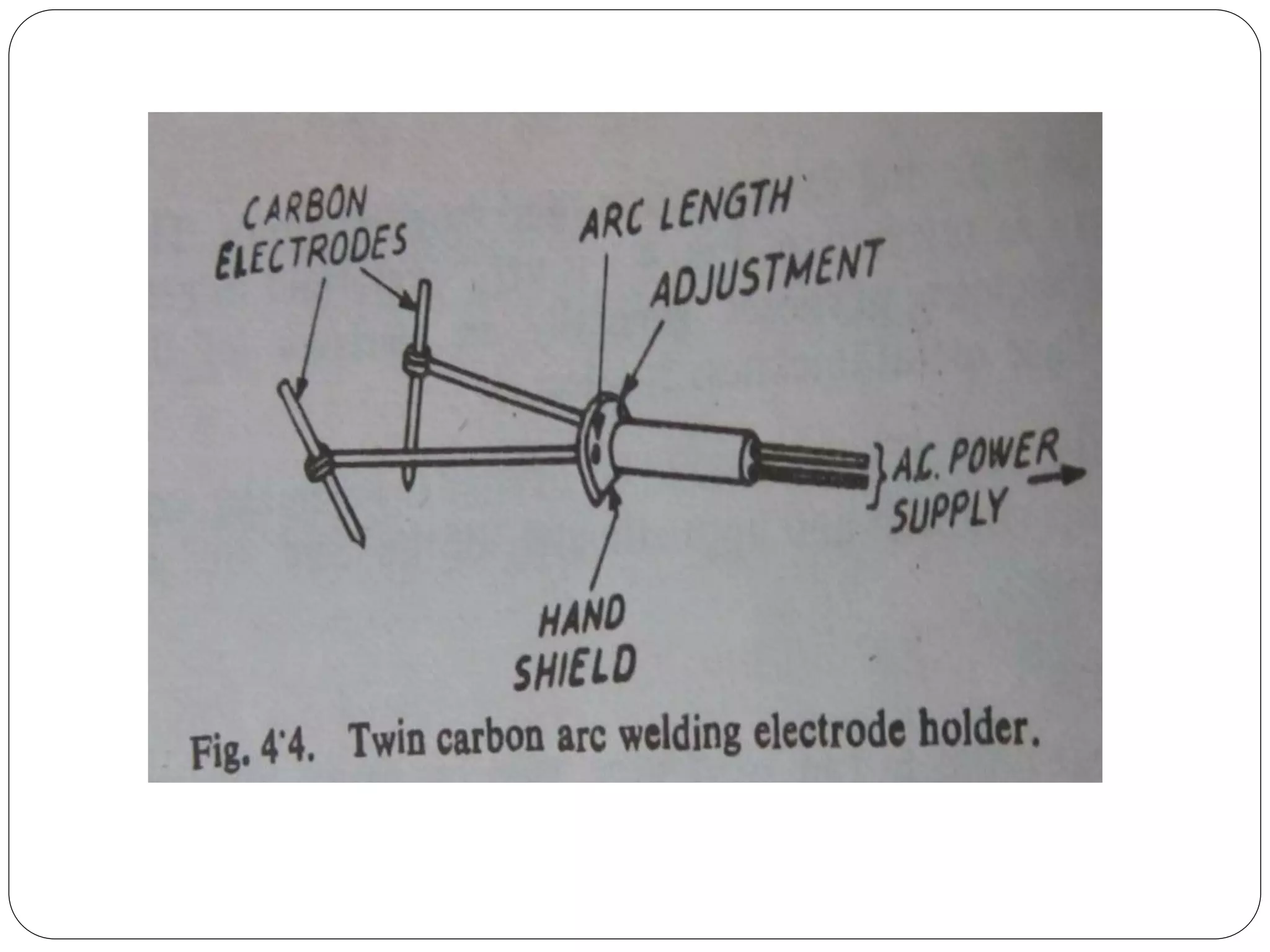

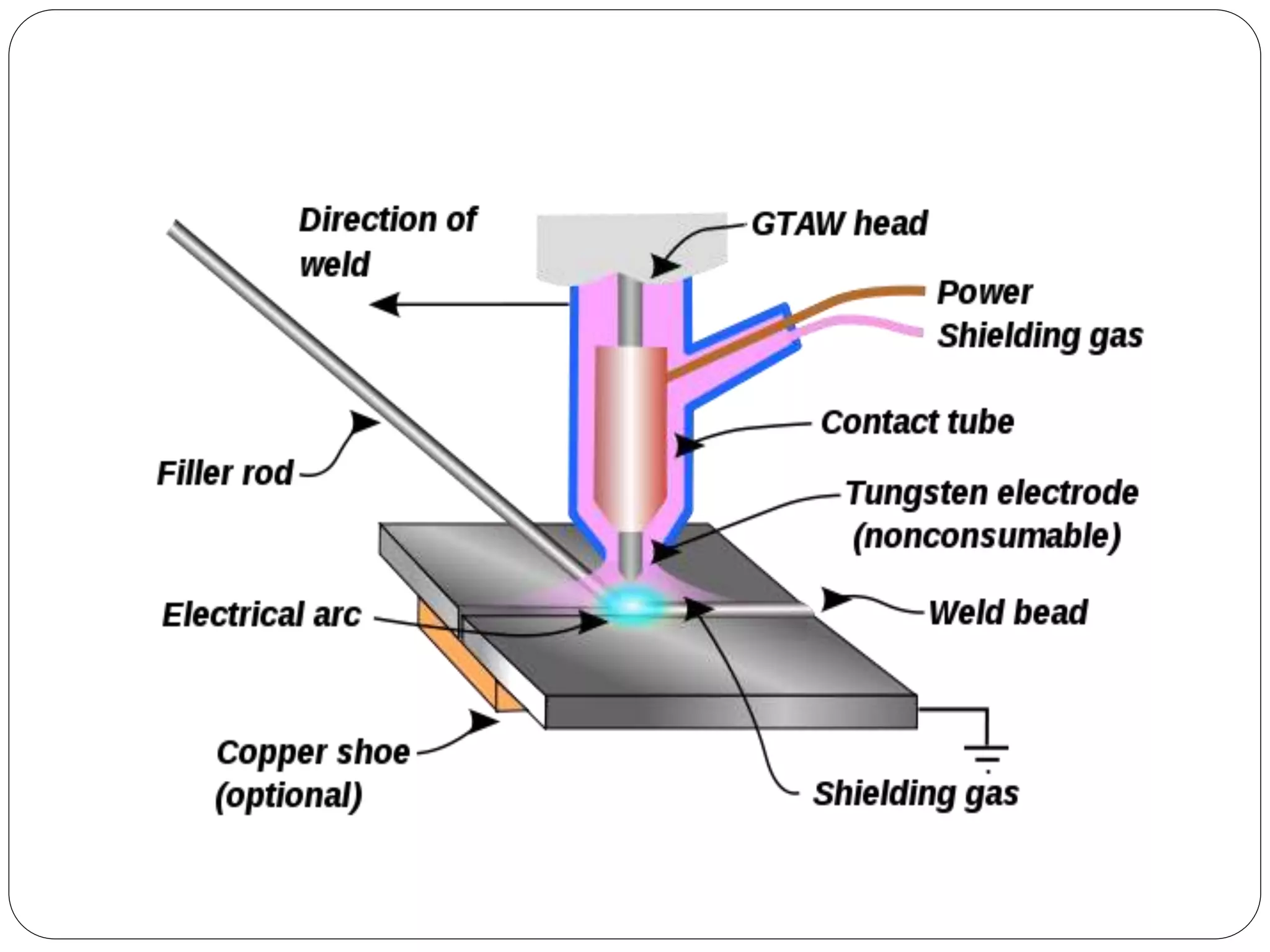

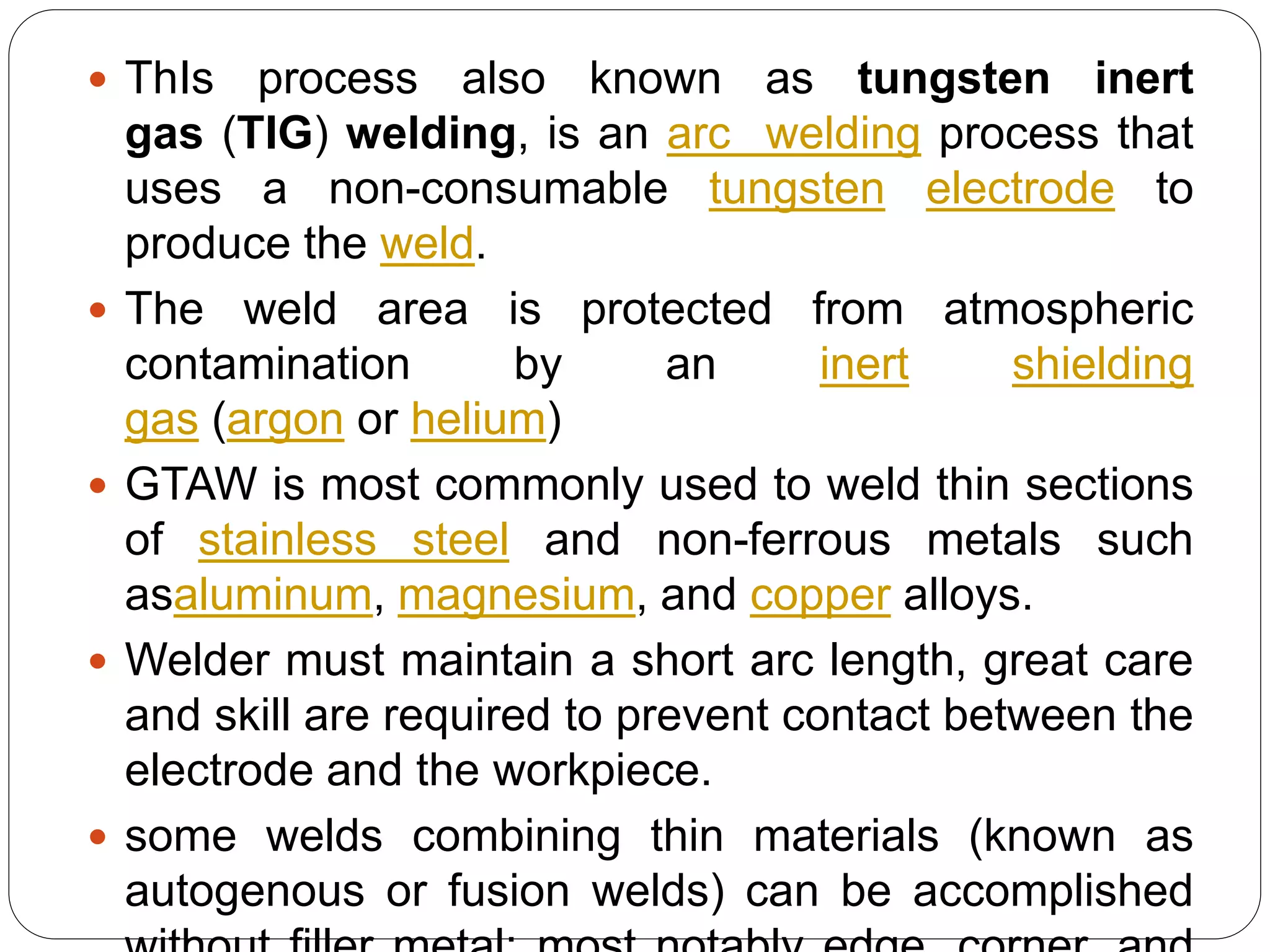

This document provides an overview of gas and arc welding processes. It discusses oxy-acetylene welding in detail, including the different types of welding flames produced (neutral, reducing, oxidizing) and equipment used such as cylinders, regulators, torches, and filler rods. Arc welding processes are also introduced, with oxy-acetylene welding described as a fusion welding technique that uses a gas flame to generate heat and join metals. The document covers advantages and disadvantages of welding in general.