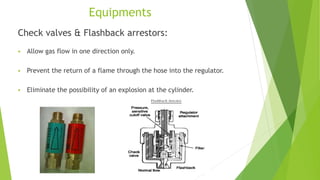

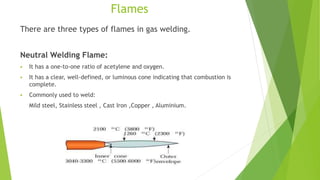

Gas welding, also known as oxy-fuel welding, is a manual metal joining process that uses gas flames to heat and melt metals. Oxygen and fuel gases like acetylene or hydrogen are supplied through hoses to a torch, which produces a flame reaching temperatures over 3,500°C. This allows melting and joining of metals, with filler rods sometimes added. Gas welding is portable and inexpensive but requires skill to control the torch and flame. It can weld steel and cast iron but is less suitable for aluminum, stainless steel, or reactive metals.