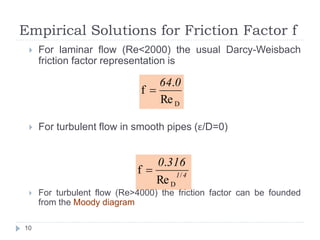

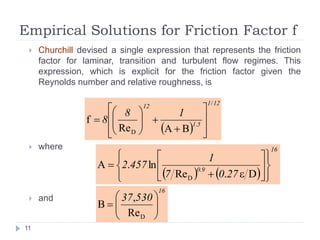

1) The document discusses methods for calculating the friction factor f in turbulent pipe flow.

2) It provides equations from Swamee-Jain, Haaland, and Churchill that can be used to explicitly calculate f based on parameters like Reynolds number, relative roughness, and pipe diameter.

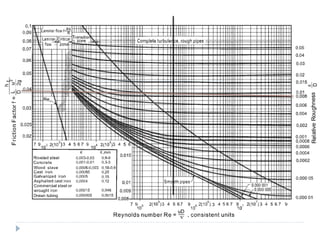

3) The example problem calculates f for water flowing in a ductile iron pipe, finding f=0.038 using Moody's diagram and the relative roughness of the pipe material.