This document provides an overview of turbulent fluid flow, including:

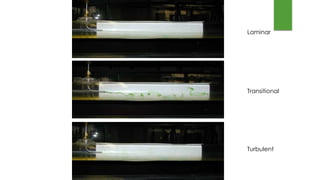

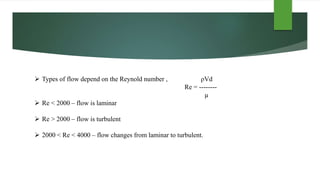

1) It defines laminar and turbulent flow and explains that turbulent flow occurs above a Reynolds number of 2000.

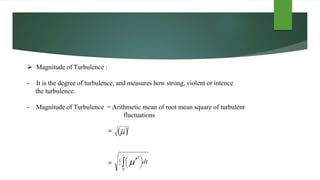

2) It describes methods for characterizing turbulence, including magnitude, intensity, and mixing length theory.

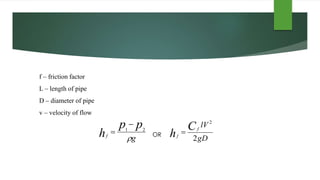

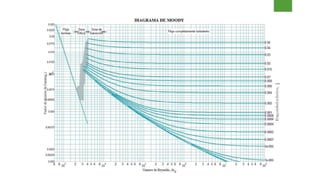

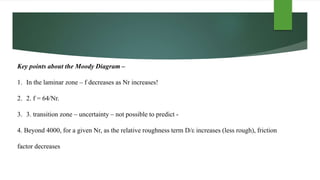

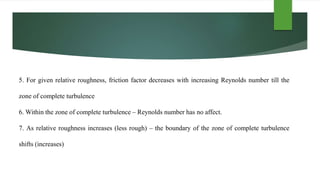

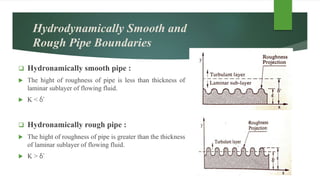

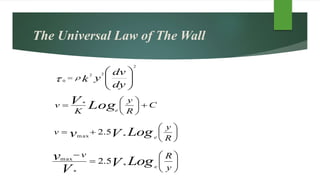

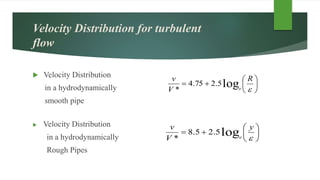

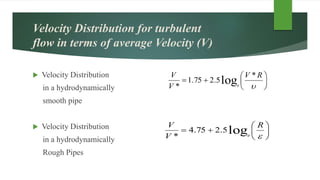

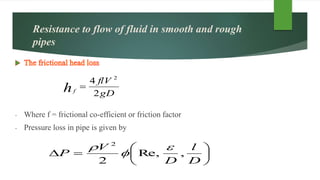

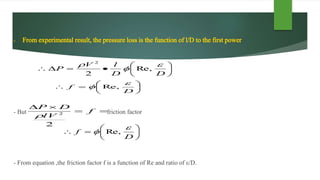

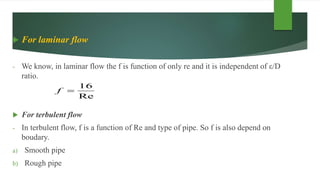

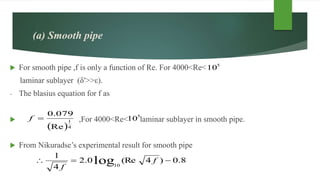

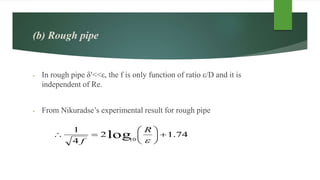

3) It discusses the universal law of the wall and how velocity is distributed in smooth and rough pipes. Friction factors depend on Reynolds number and relative roughness.

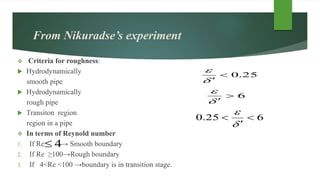

4) Experimental results from Nikuradse are presented showing relationships between friction factor and Reynolds number/relative roughness that can be used to model pressure losses in pipes.

![Gandhinagar Institute of Technology

Subject :- Fluid Mechanics

– Pavan Narkhede [130120119111]

Darshit Panchal [130120119114]

Topic :- Turbulent Flow

:

Prof.Jyotin kateshiya

MECHANICAL ENGINEERING

4th - B : 2](https://image.slidesharecdn.com/turbulentflow-150309105937-conversion-gate01/75/Turbulent-flow-1-2048.jpg)