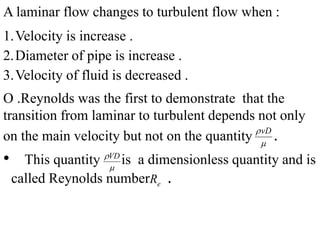

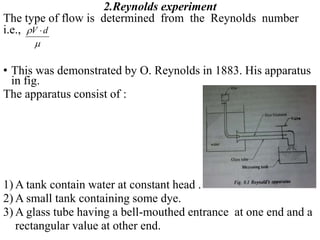

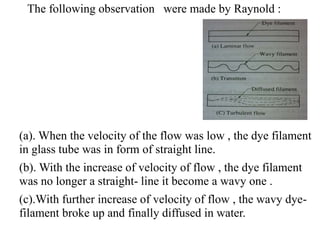

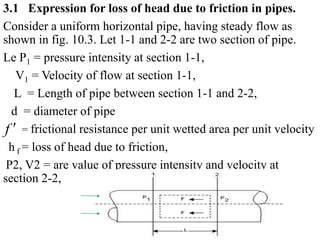

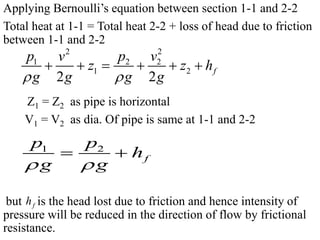

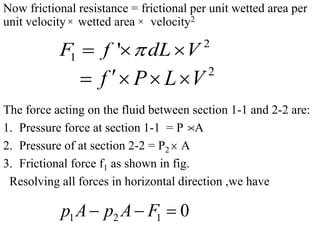

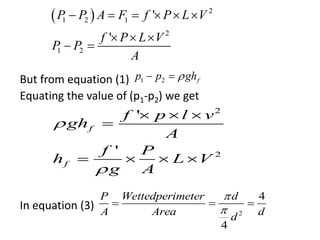

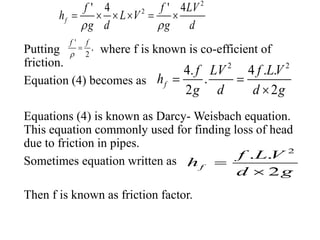

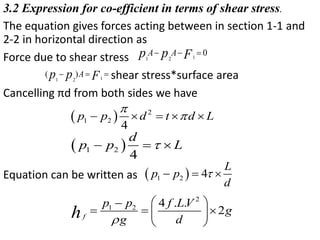

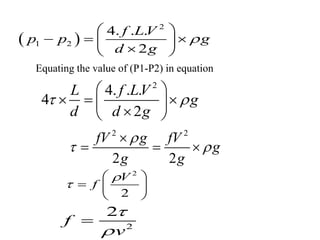

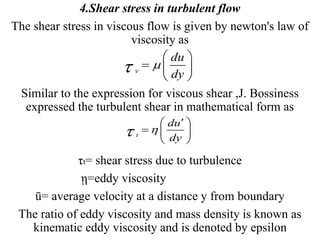

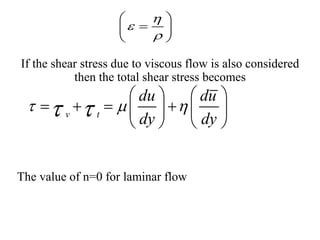

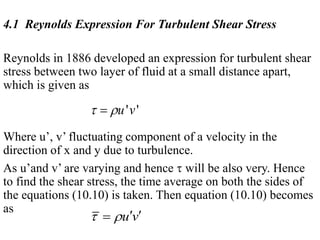

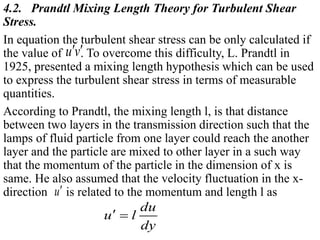

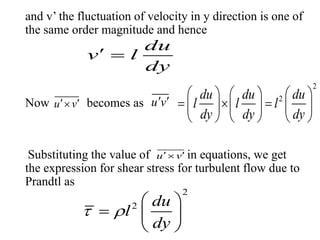

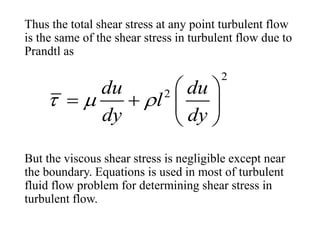

The document discusses fluid mechanics, specifically focusing on turbulent flow and its characteristics, including its transition from laminar flow based on Reynolds number. It explains how factors like velocity and pipe diameter affect flow type and describes the experimental findings of Reynolds regarding pressure loss and friction in turbulent flow. Additionally, it elaborates on shear stress in turbulent flow, including Prandtl's mixing length theory for calculating turbulent shear stress.