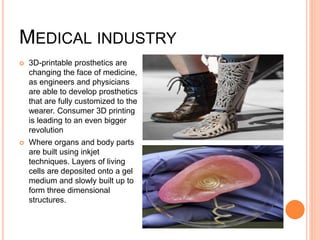

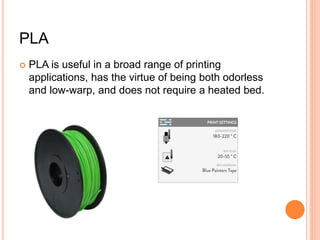

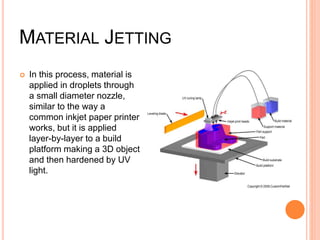

The document provides a comprehensive overview of 3D printing, detailing its principles, methods, types of printers, and applications across various industries, including medical and automotive. It discusses the materials used, the advantages and disadvantages of the technology, as well as predictions for its future impact on commerce and manufacturing. Additionally, it emphasizes the importance of CAD modeling and repair processes in creating 3D-printed objects.