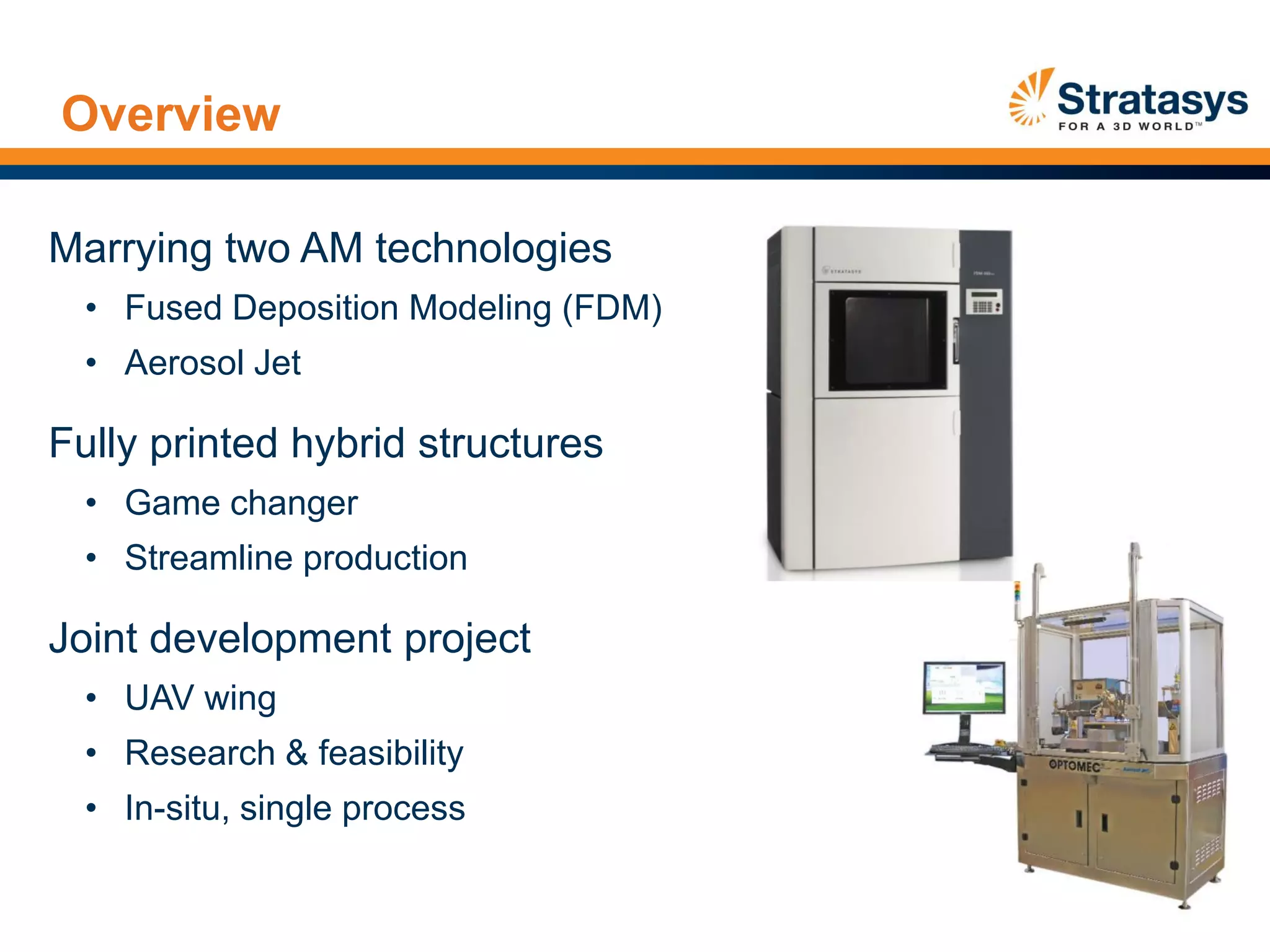

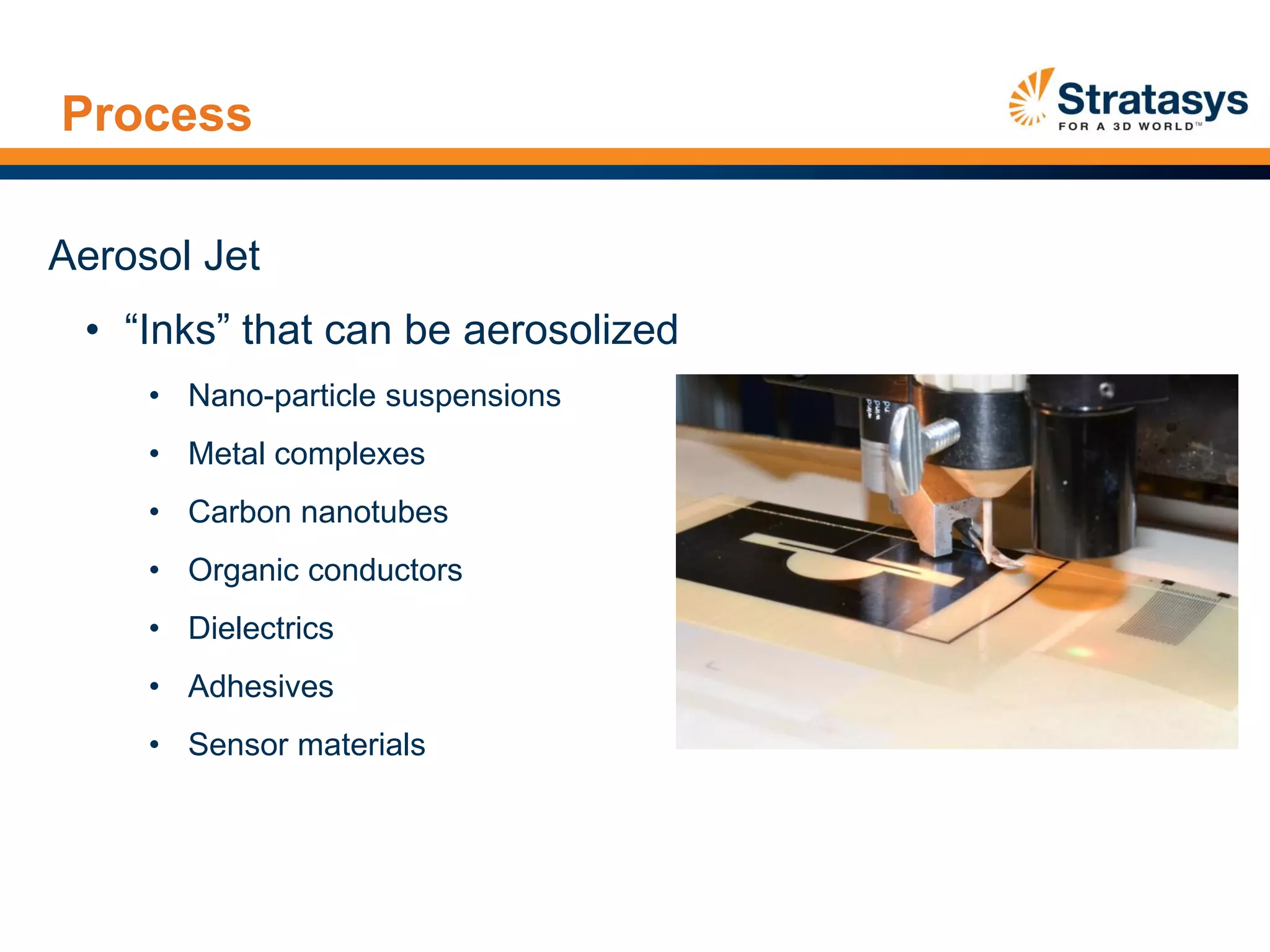

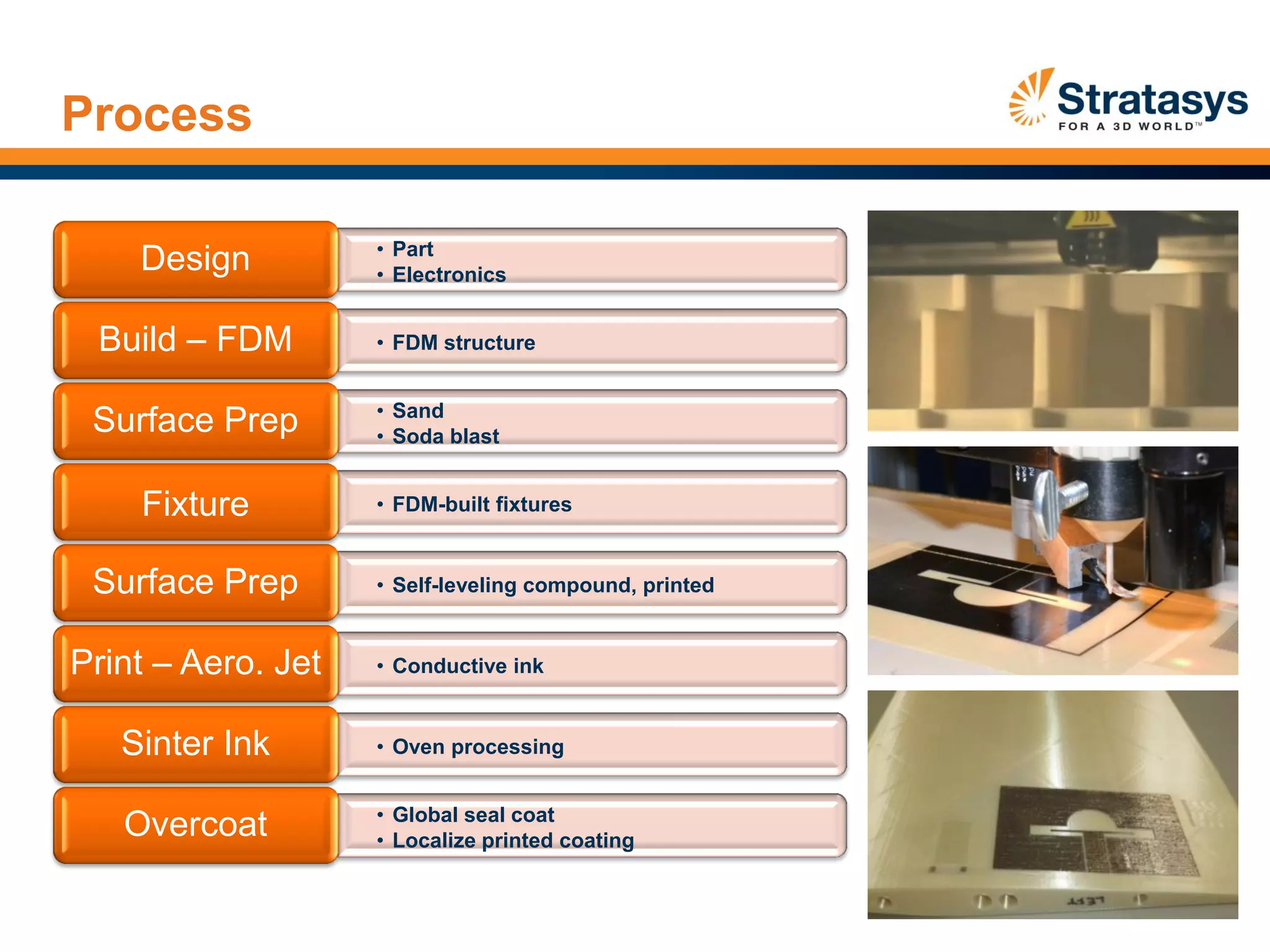

The document discusses Stratasys's integration of additive manufacturing technologies, specifically Fused Deposition Modeling (FDM) and aerosol jet printing, to create advanced electro-mechanical devices. It covers the advantages of these technologies, including reduced part count, increased functionality, and cost savings, alongside specific projects like the UAV wing. Future work aims to enhance design rules and performance expectations while expanding applications across various industries.