The document provides an overview of the evolution of 3D printing. It discusses the history of 3D printing technologies from 1987 to present day. Key developments include the invention of stereolithography in 1987, commercialization of fused deposition modeling (FDM) in 1991, and the expansion of available materials like plastics, metals, and food items in recent years. The document also outlines several applications of 3D printing in fields such as aerospace, prosthetics, footwear, jewelry, and construction.

![5

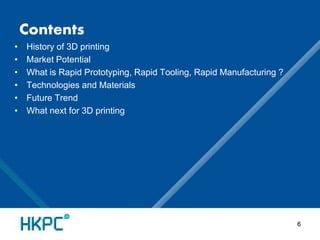

Media Attention to 3D printing

明報專題B9 [28/6/2013] 亞洲電視金錢世界21/4/2013]

星島日報[9/8/2013]

頭條日報[17/8/2013 ]

新城財經台[14/1/2014]

信報財經新聞A14 [9/7/2013]](https://image.slidesharecdn.com/bryanso-140828162621-phpapp02/85/Bryan-So-5-320.jpg)

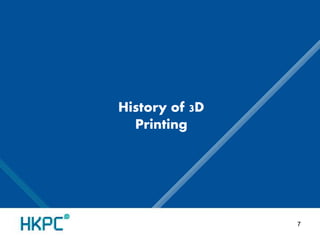

![New York-based Jewelry American Pearl (http://www.americandiamondshop.com/)

allow customers to fully customize their own jewelry to their exact specifications, by

using 3D printer Solidscape T76 to create a lost-wax casting mold and then pours gold

to fashion the final piece. Eddie Bakhash, CEO and son of the founder of American

Pearl said "In the old way, jewelers had to spend a lot of hours carving [by hand]. It

would take me two weeks to create that piece. We can do it in a day now.“

17

3D Printing Application –

Customized Jewelry](https://image.slidesharecdn.com/bryanso-140828162621-phpapp02/85/Bryan-So-17-320.jpg)

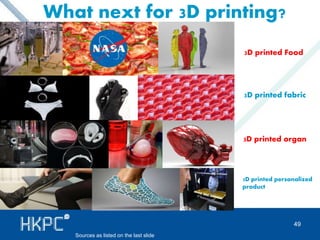

![46

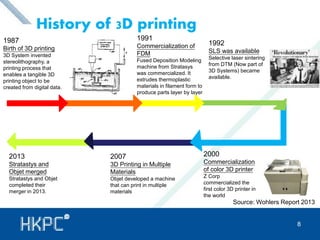

3D printing Novel Materials

i.materialise® Rubber-Like Material

[TPU 92A-1]

Textile Food

1. www.slashgear.com/3d-printing-gets-squishy-with-new-materials-from-materialise-and-shapeways-

31284481/

2. sbir.gsfc.nasa.gov/SBIR/abstracts/12/sbir/phase1/SBIR-12-1-H12.04-9357.html

3. www.3ders.org/articles/20131023-cu-boulder-researchers-develop-4-d-printing-technology-for-composite-

materials.html

Macronutrients

Flavors and texture modifiers

“Shape memory“ polymer fibers Living human cells

Fibers Tissue Engineering](https://image.slidesharecdn.com/bryanso-140828162621-phpapp02/85/Bryan-So-46-320.jpg)