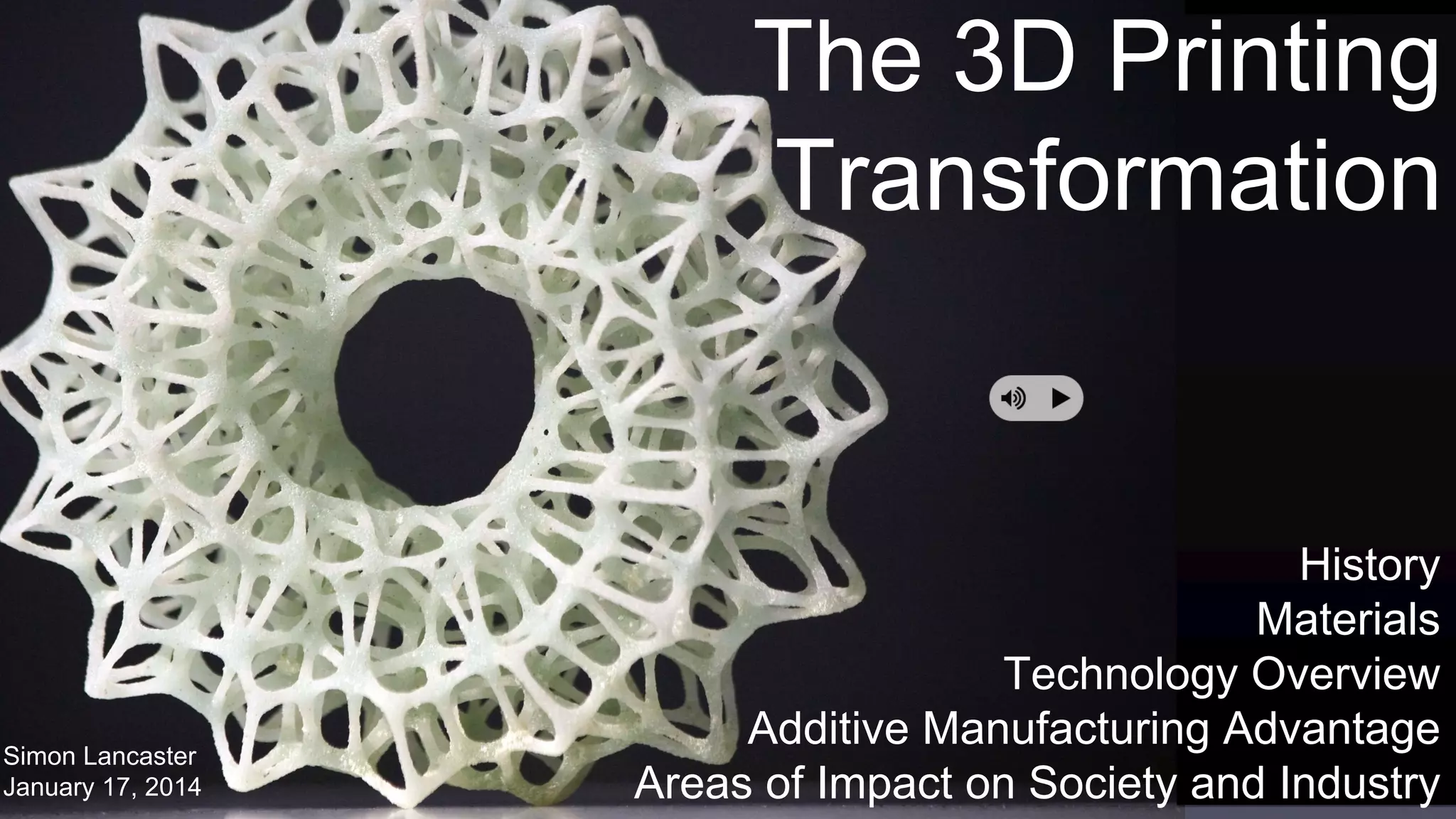

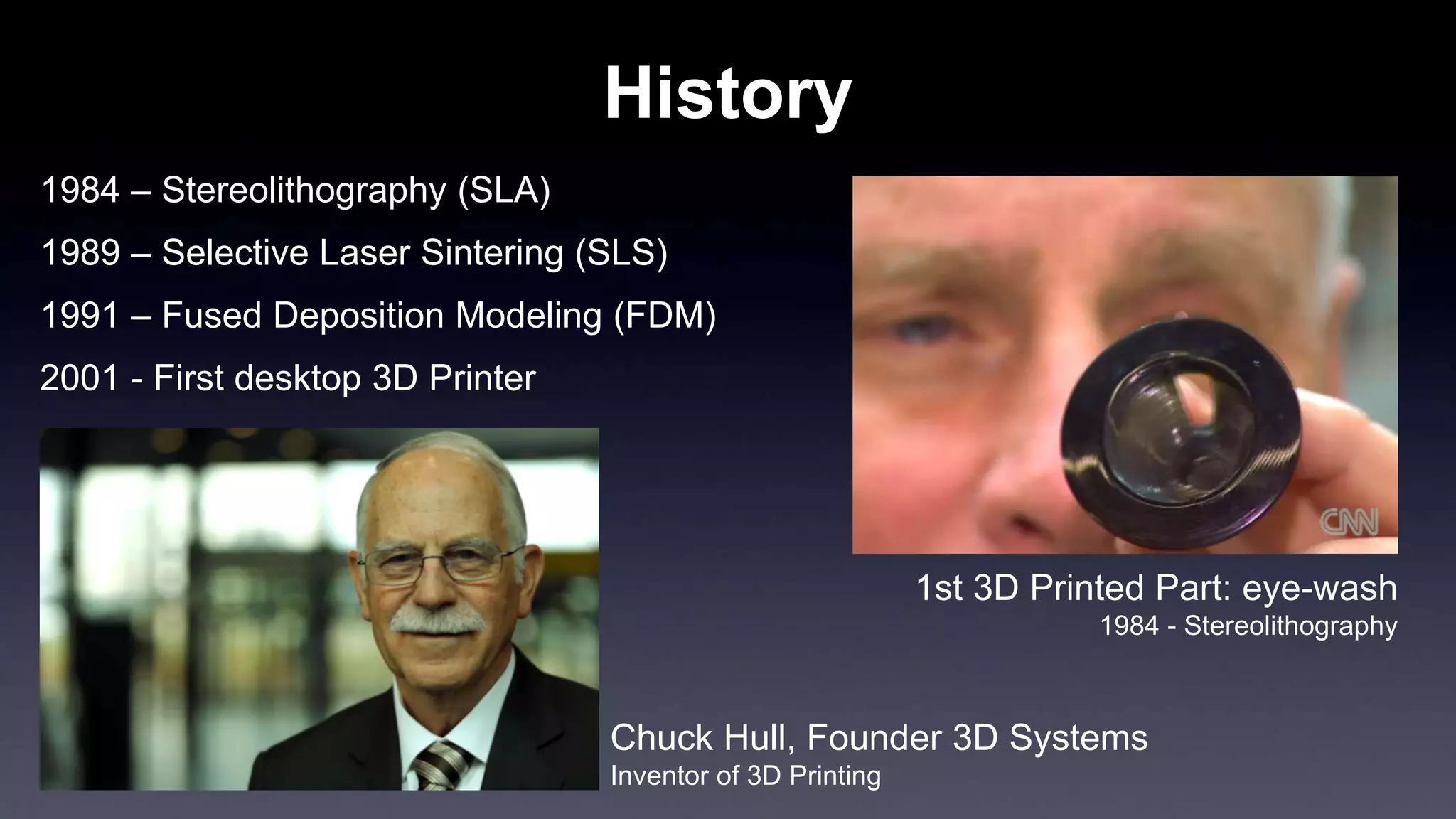

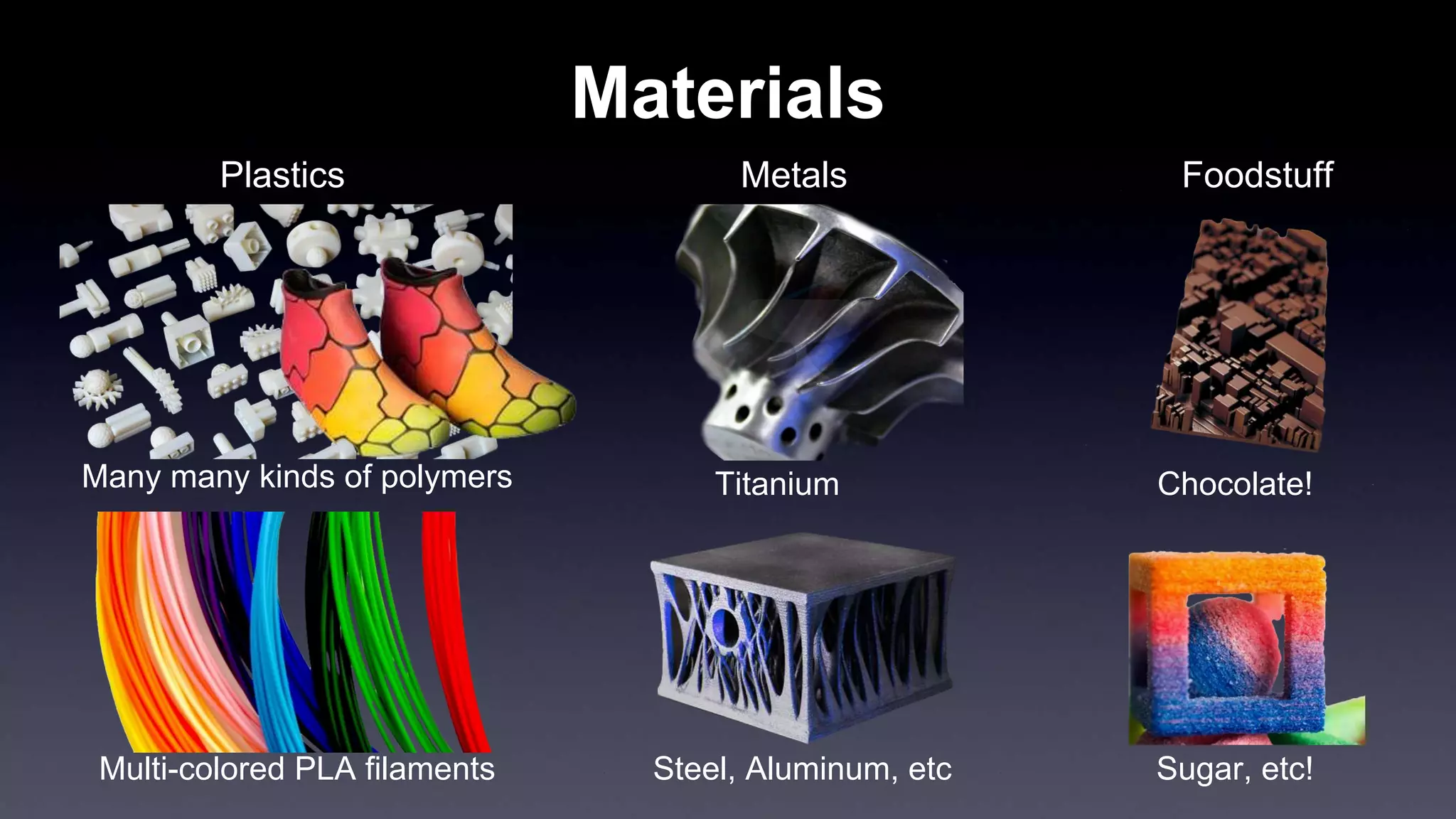

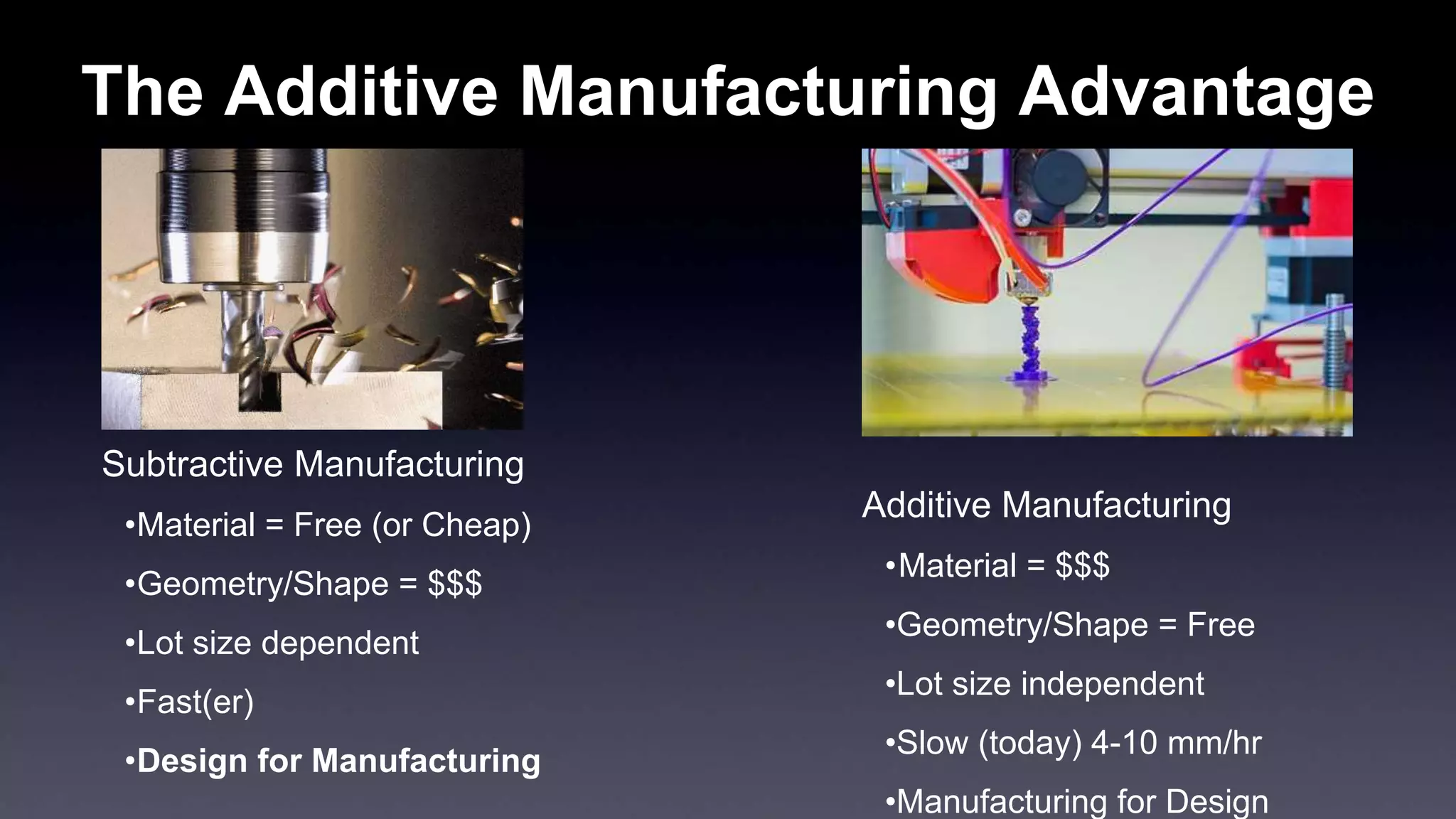

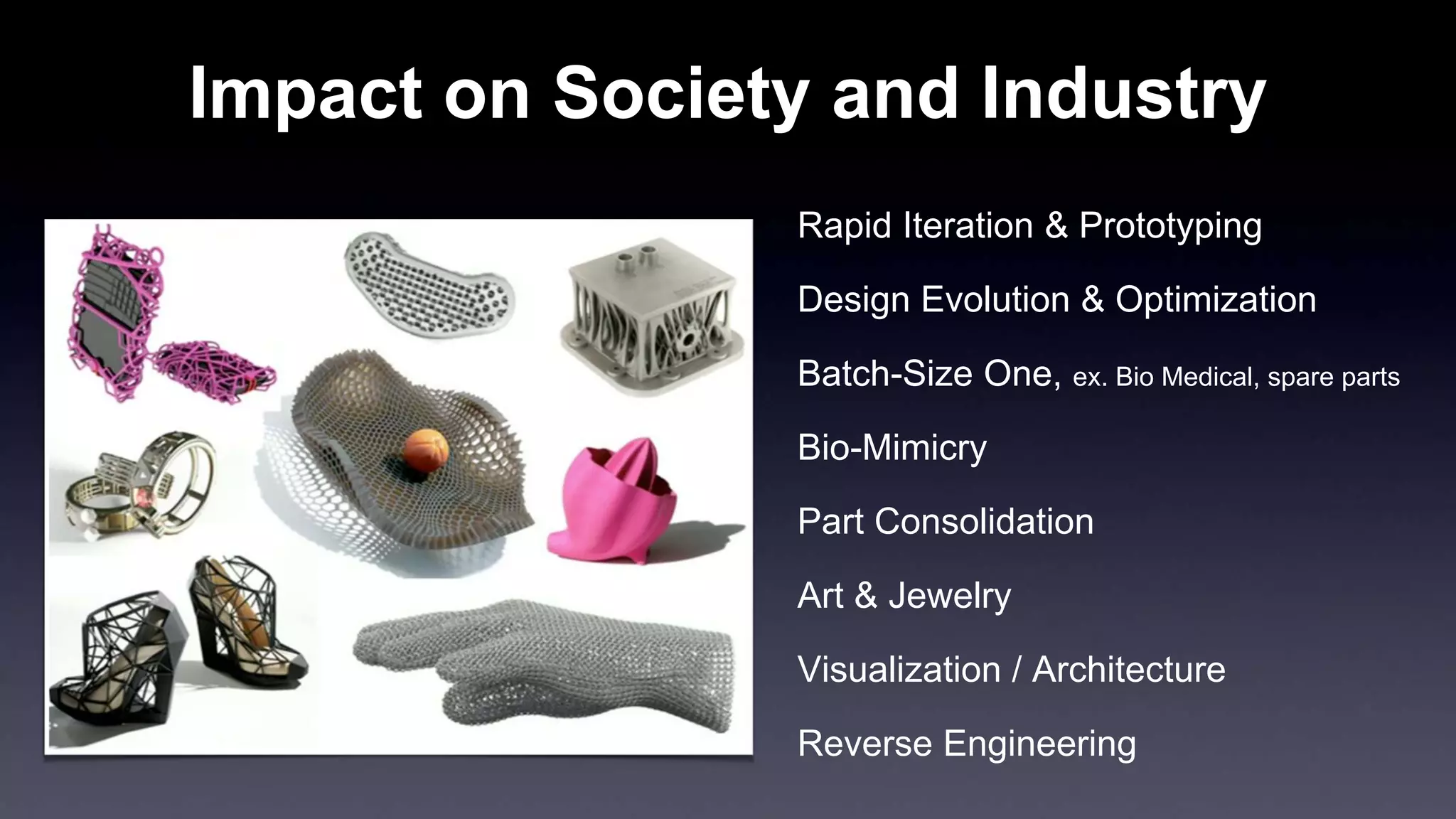

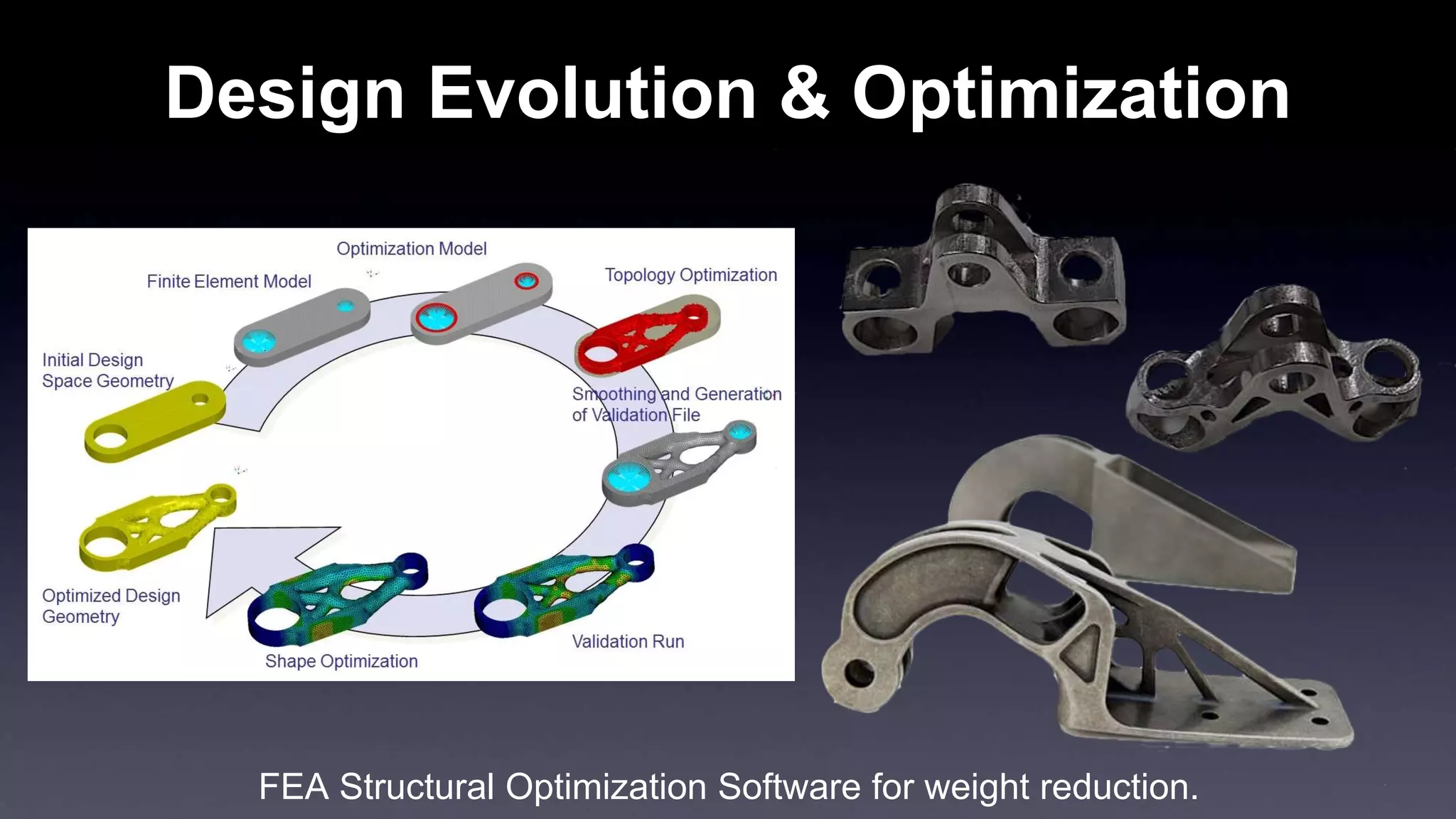

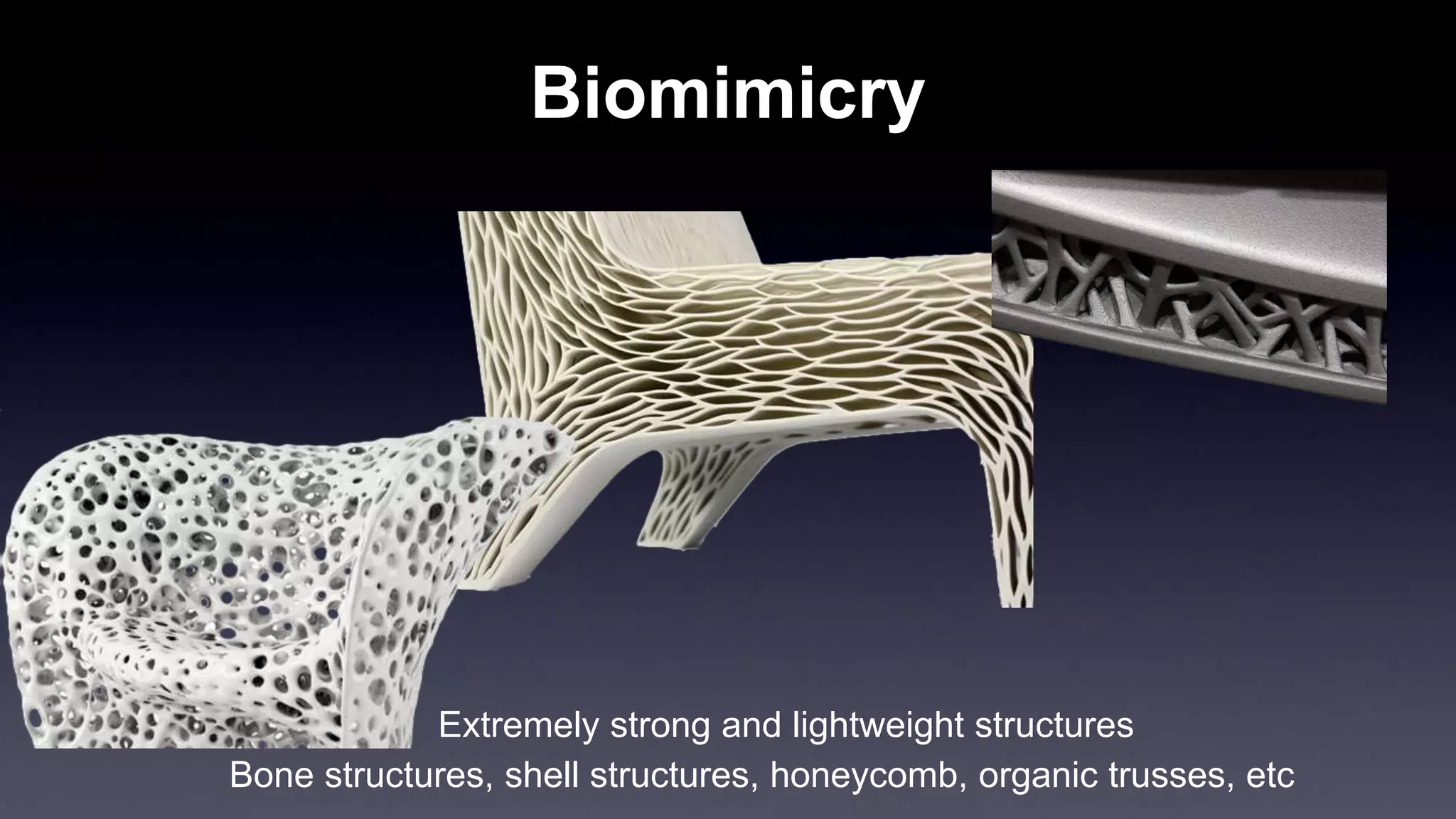

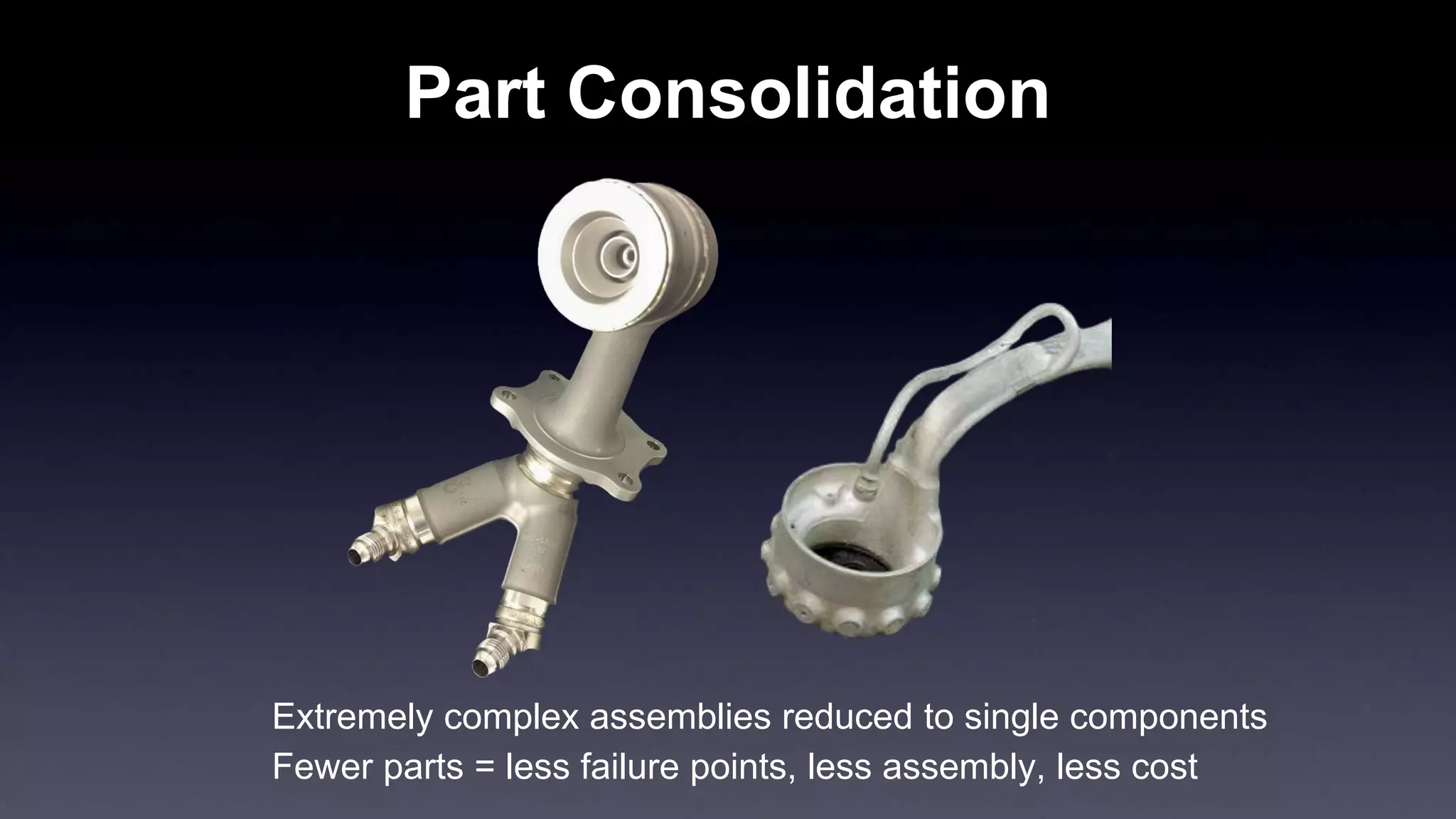

This document provides an overview of 3D printing including its history, materials used, and technologies. It discusses how 3D printing works by adding material layer by layer (additive manufacturing) compared to traditional subtractive manufacturing. The advantages of 3D printing include the ability to create complex geometries easily without limitations of traditional manufacturing as well as batch size of one. The document outlines several impacts of 3D printing on industries and society such as rapid prototyping, design evolution, customized medical devices, art, and more.