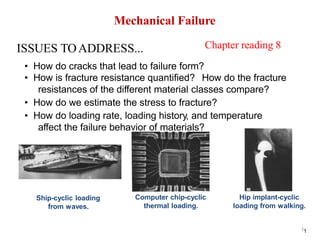

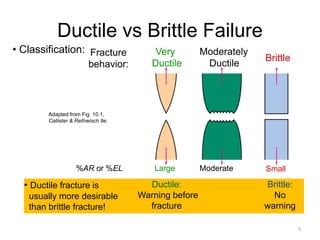

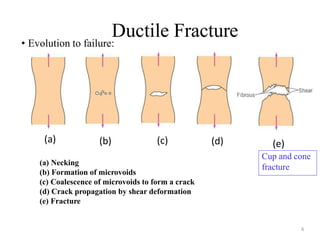

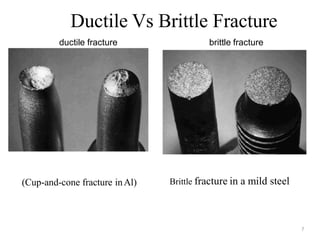

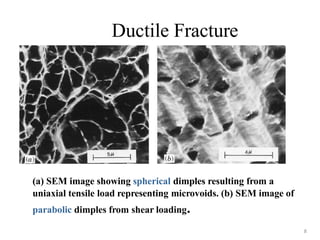

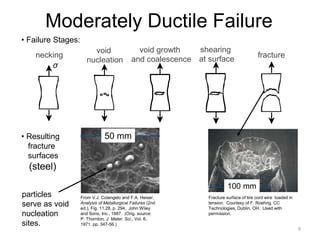

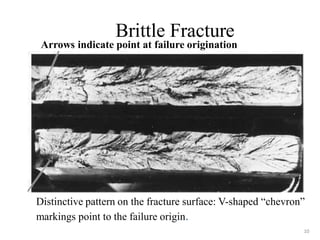

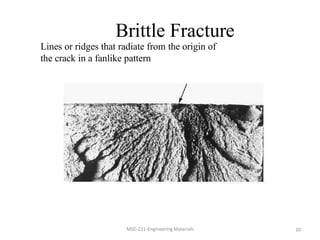

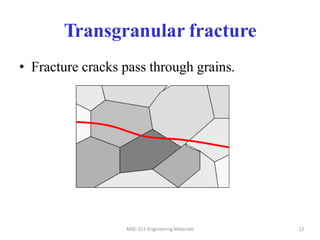

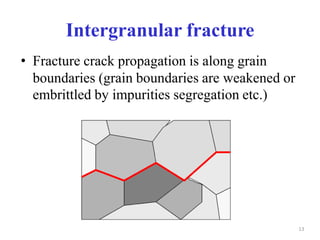

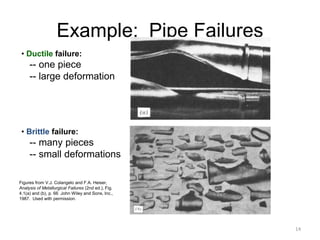

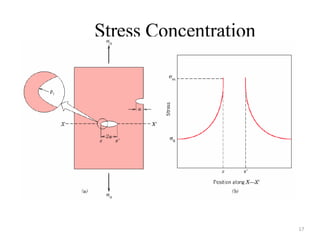

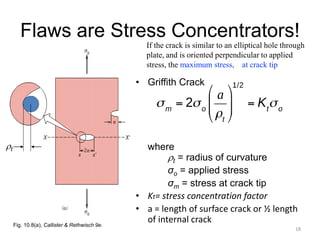

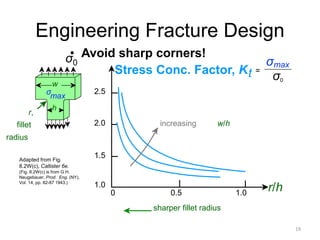

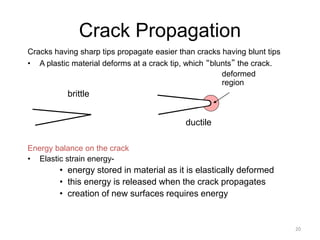

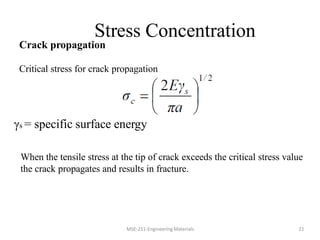

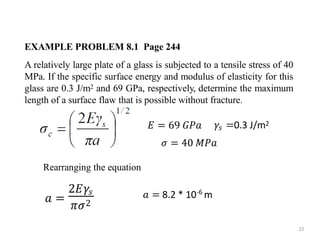

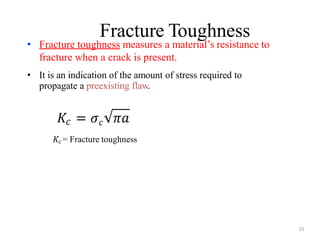

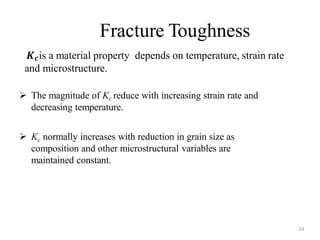

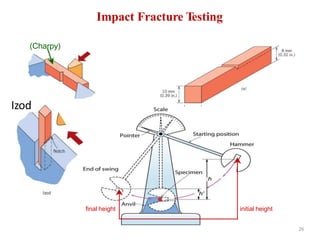

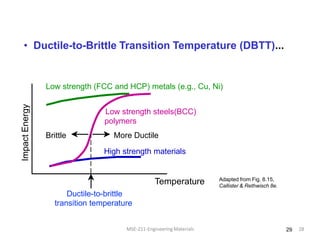

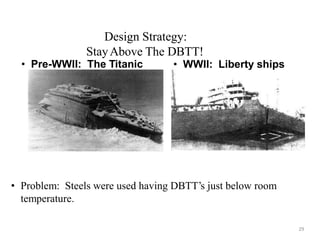

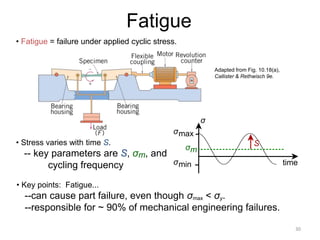

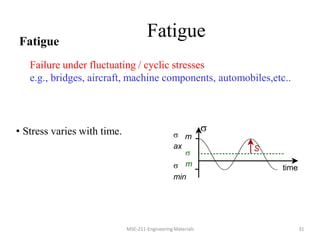

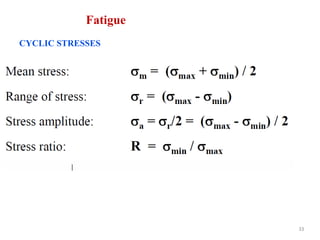

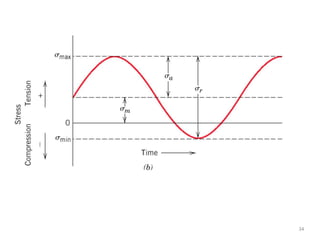

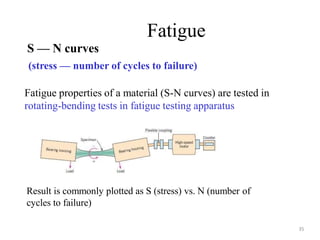

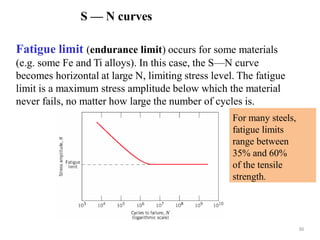

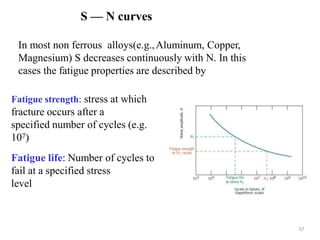

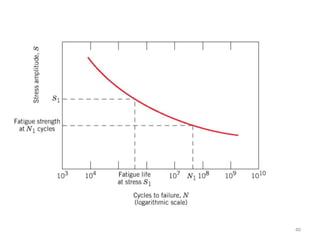

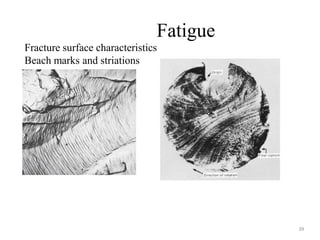

This document discusses various failure modes in materials including cracks, fracture, fatigue, and the ductile to brittle transition. It addresses how cracks form and propagate, how fracture resistance is quantified, and factors that influence failure such as loading rate, temperature, and stress concentration. Ductile fracture involves plastic deformation while brittle fracture does not. Fatigue failure can occur at stresses lower than the material strength from cyclic loading. The ductile to brittle transition temperature depends on the material. Fracture toughness measures resistance to crack propagation.