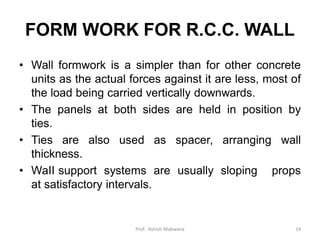

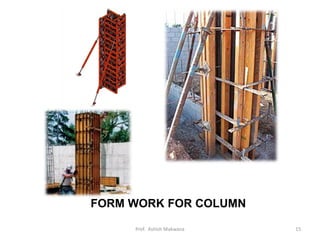

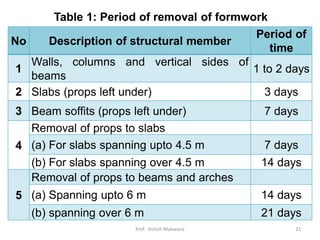

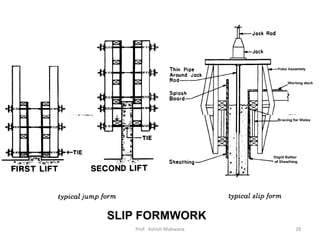

The document outlines the various aspects of formwork used in civil engineering, detailing types, materials, and design considerations for concrete construction. It emphasizes the importance of formwork in providing temporary molds for concrete and discusses techniques for economy, safety, and efficacy in formwork design. Additionally, it covers specific applications for walls, slabs, beams, and columns, as well as methods like slip formwork and falsework for bridges.