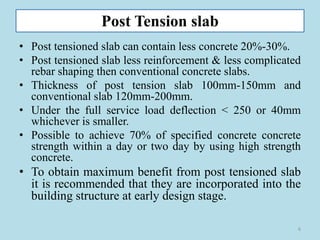

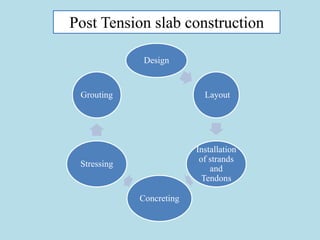

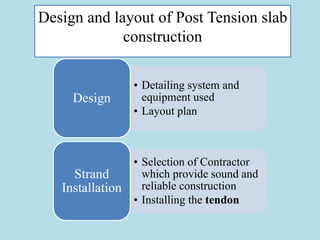

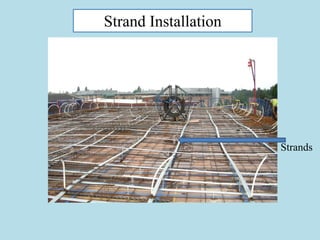

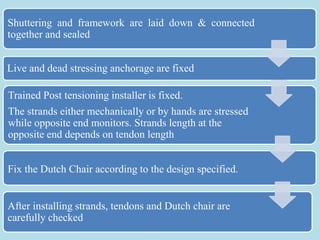

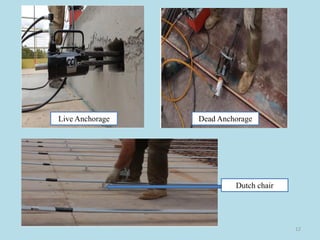

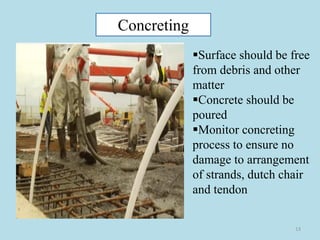

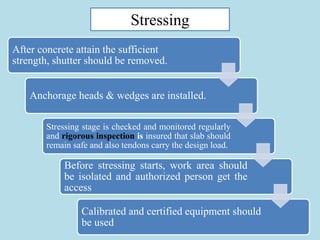

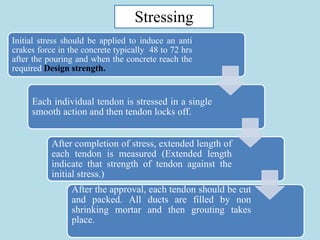

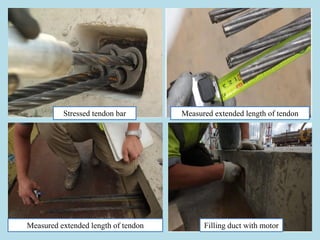

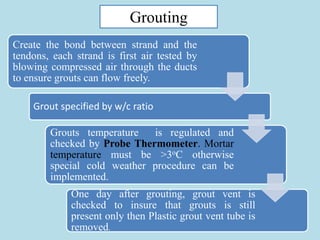

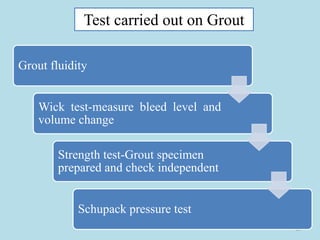

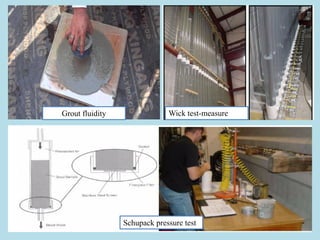

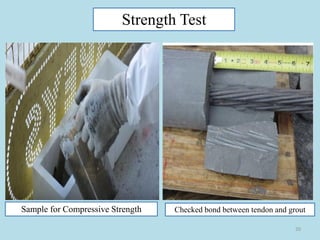

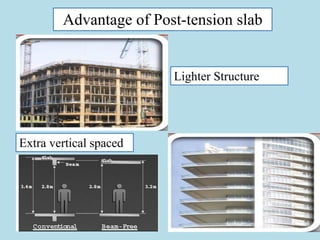

This document provides an overview of the construction process for post-tension slabs. It begins with a brief history of post-tensioned concrete before defining post-tension slabs as reinforced concrete slabs supported directly by columns without beams. The construction process involves installing strands or tendons in ducts before pouring concrete, stressing the strands after the concrete reaches strength, and then grouting the ducts. Key advantages of post-tension slabs are that they are lighter, allow for greater flexibility in design, and have reduced costs compared to conventional slabs.

![Department of Civil Engineering

Indian Institute of Technology Kanpur

Arvind Vishavkarma

Textbooks or Reference Materials

[1]https://www.youtube.com/watch?v=jeHI92RYr5Q

[2]http://www.fdot.gov/structures/structuresresearchcenter/Final%20Reports/B

C354_73.pdf

[3]http://www.buildersshow.com/Documents/course_handouts/Post

Tensioned%20Concrete%20in%20Residential%20Construction.pdf

[4] http://www.cclint.com/uploads/PDFs/Post-tensioned-Slabs.pdf

CONSTRUCTION OF

POST-TENSION SLAB](https://image.slidesharecdn.com/constructionofposttensionslab-180313055249/75/Construction-of-post-tension-slab-1-2048.jpg)