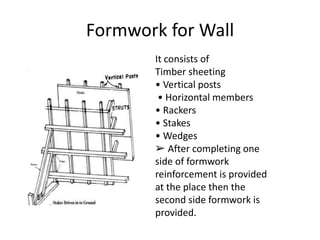

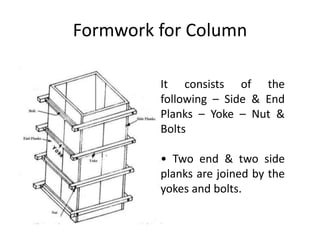

Formwork is a mold used in concrete construction to shape and support the material until it hardens, with various types made from steel, timber, and other materials. Key qualities include strength, reuse potential, economic considerations, and compliance with design standards. The document discusses the different types of formwork for structural components, advantages of steel over timber, and factors affecting formwork cost and maintenance.