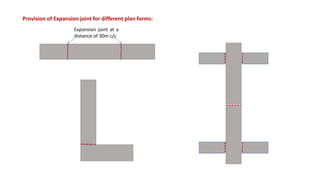

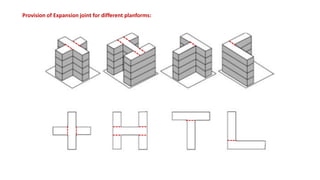

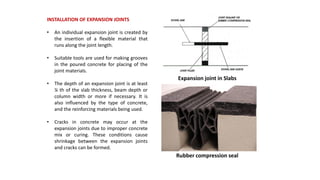

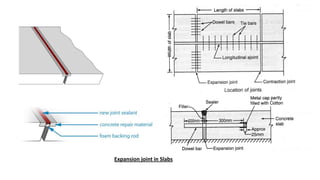

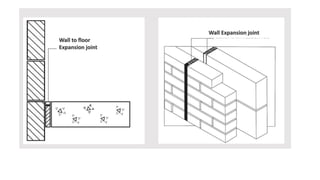

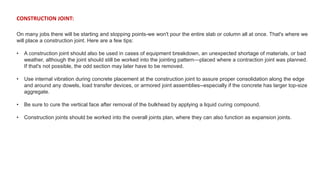

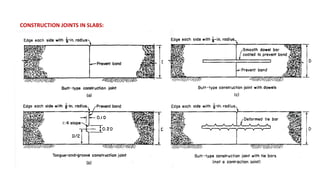

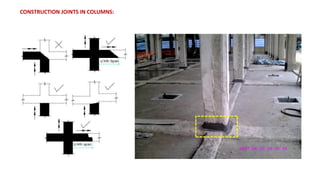

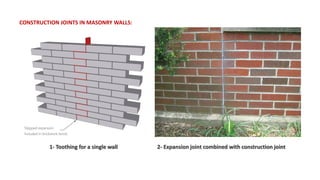

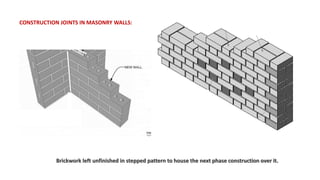

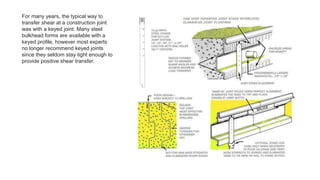

Expansion and construction joints are necessary in concrete construction to prevent cracking due to concrete movement. Expansion joints allow concrete to expand and contract with temperature changes, and are incorporated in foundations, walls, roofs, and paving. They are carefully designed and located to mitigate stresses. Construction joints are used when concrete placement is stopped, such as due to equipment issues, and are incorporated into the planned joint layout. They require proper consolidation and curing. Both expansion and construction joints are used in slabs, columns, and masonry walls.