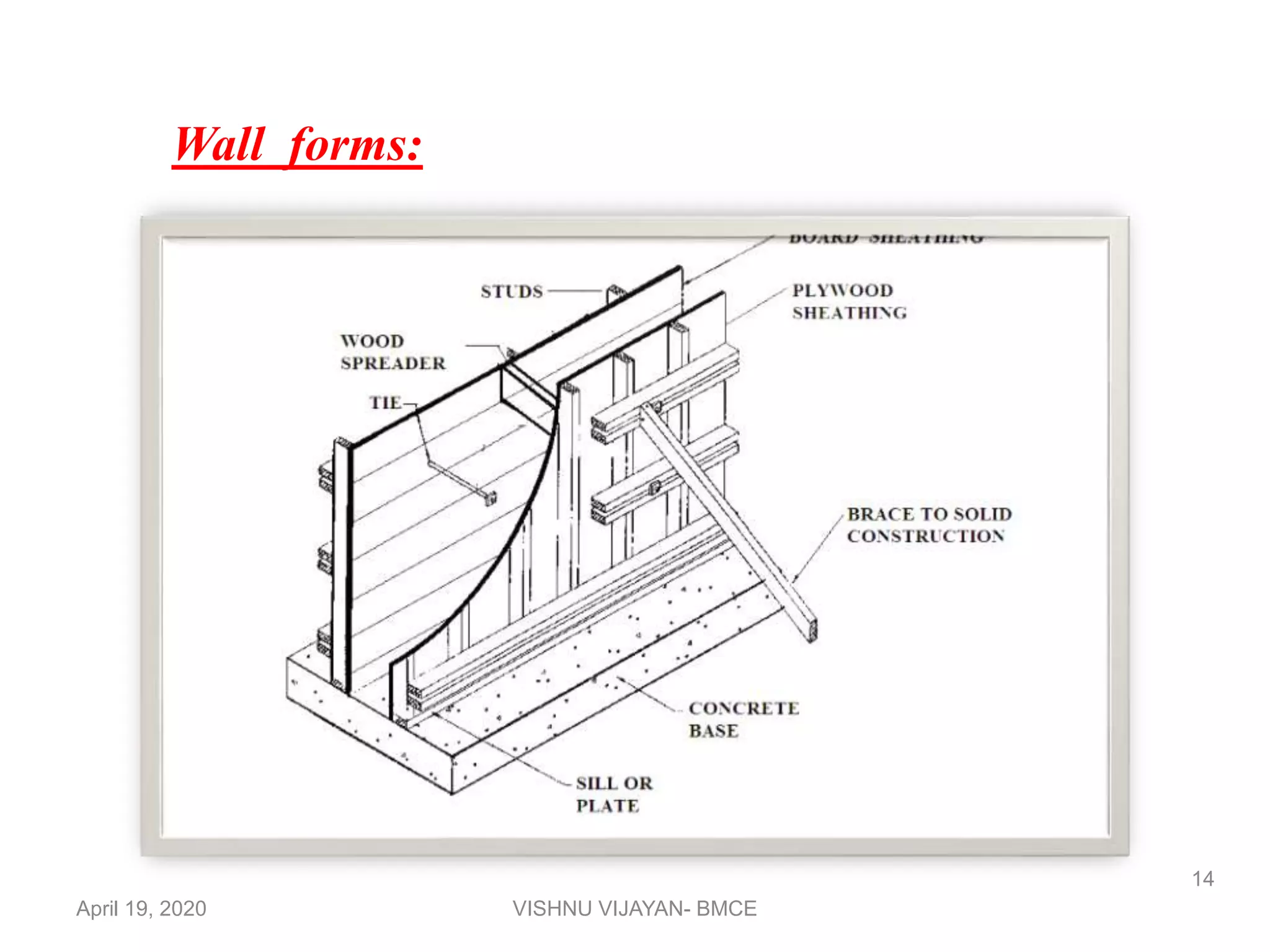

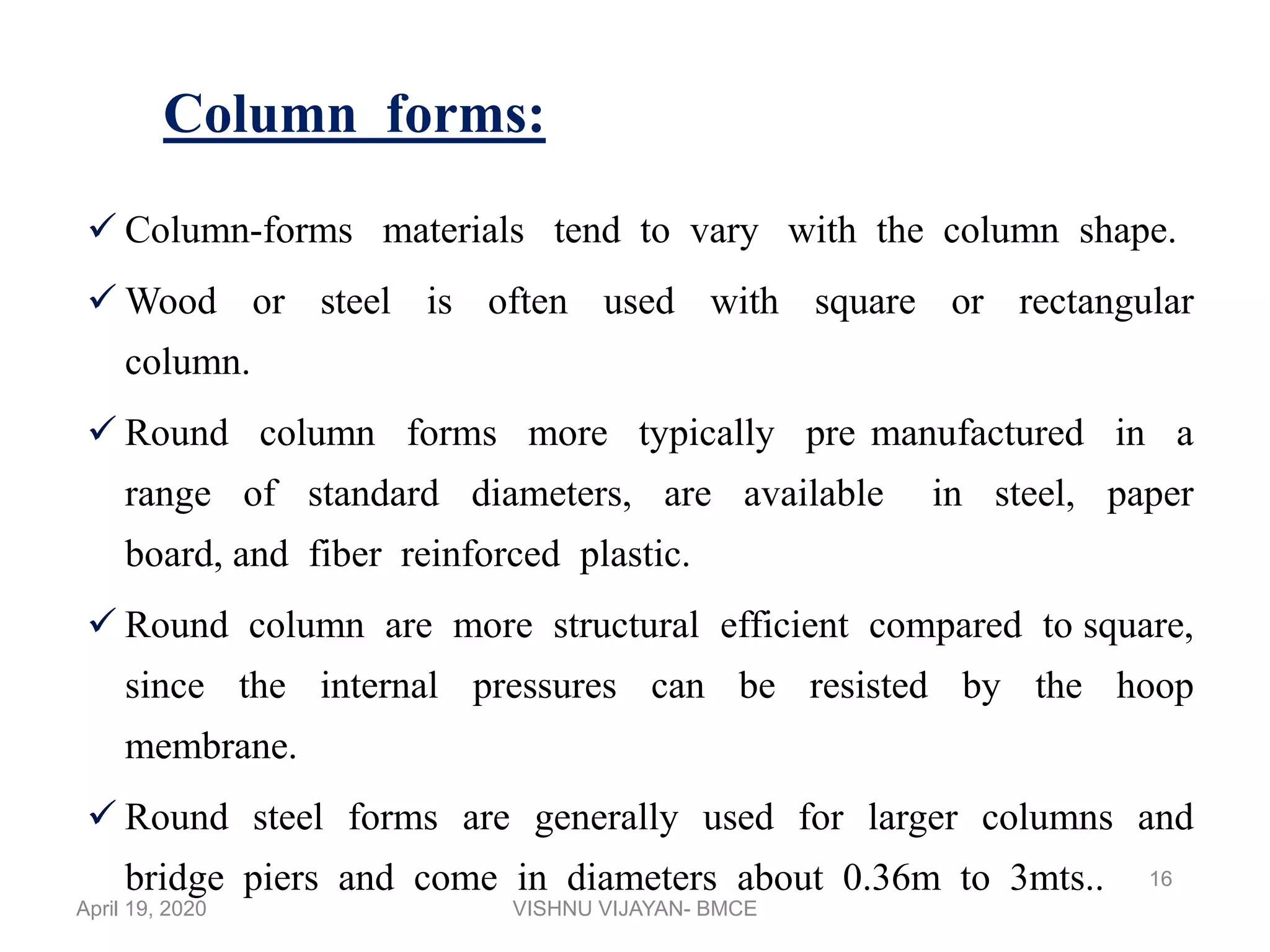

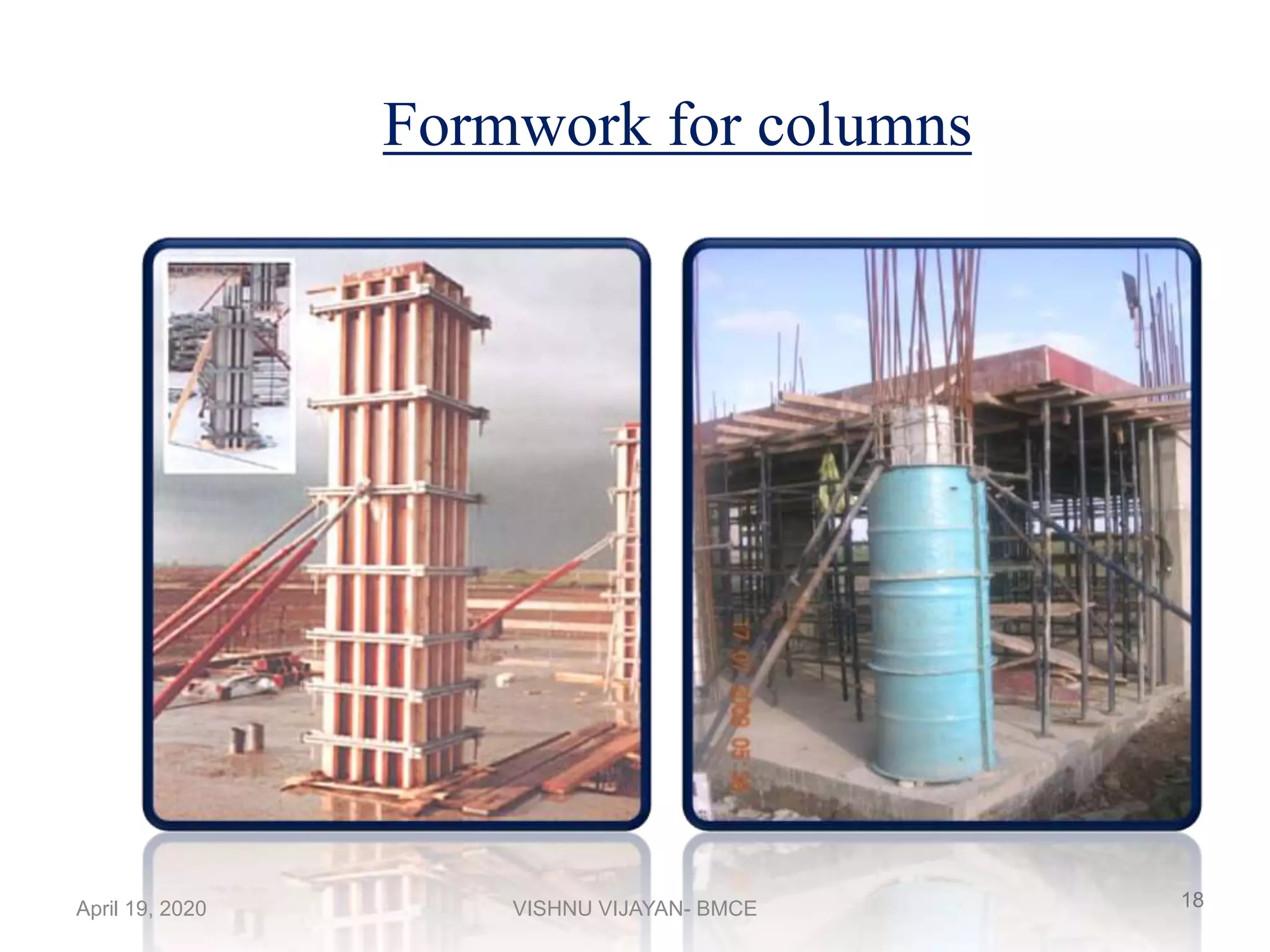

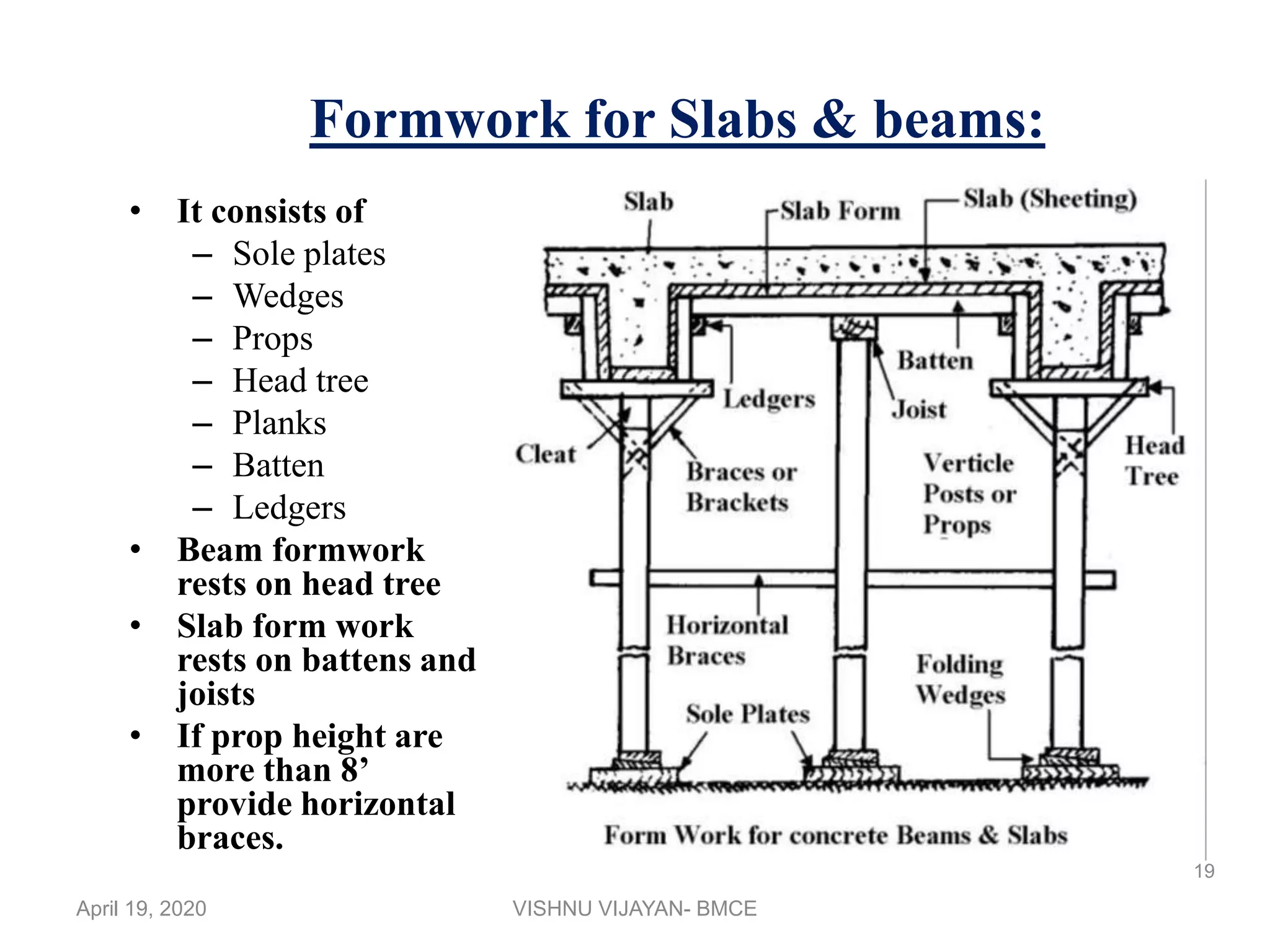

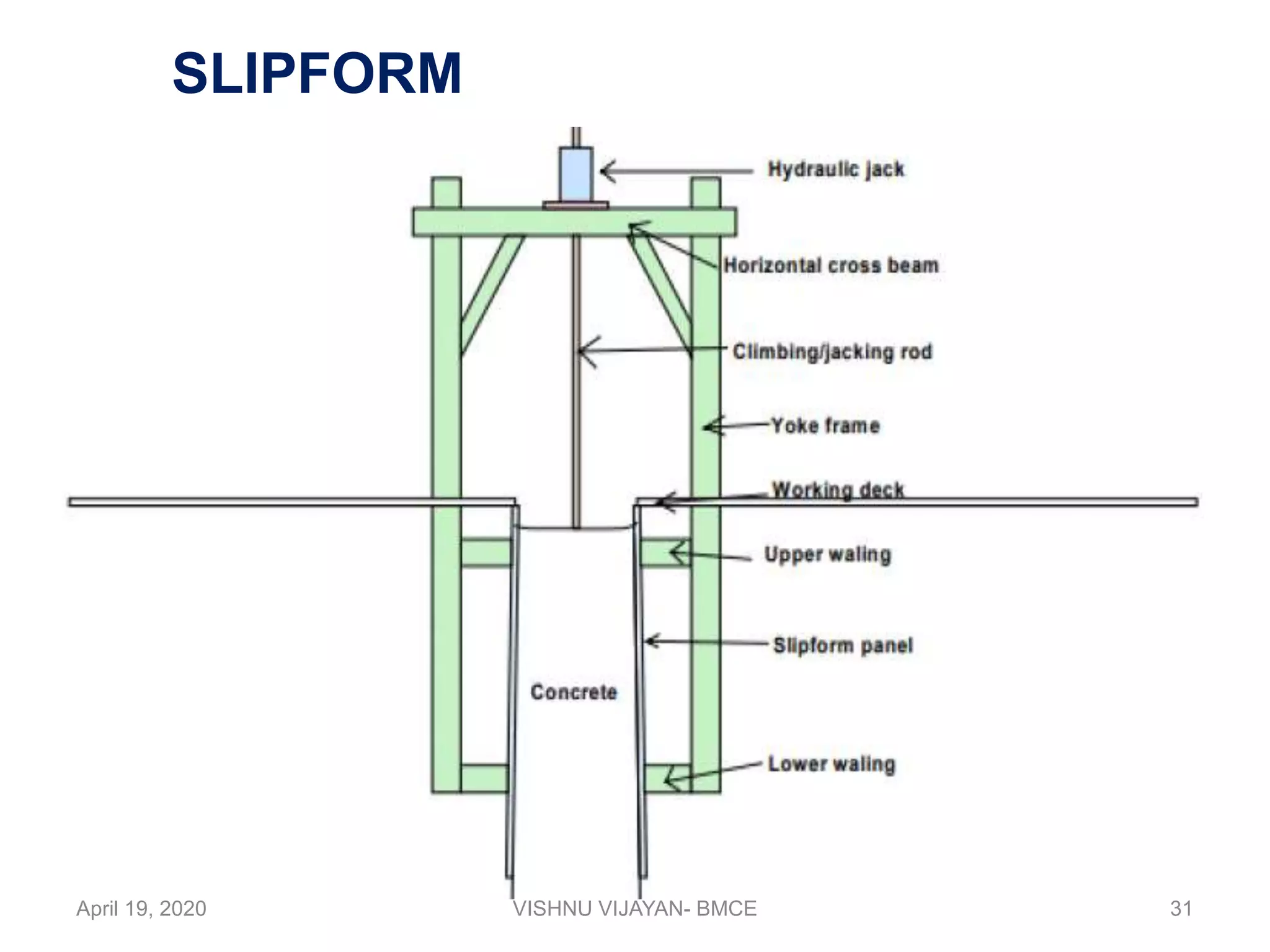

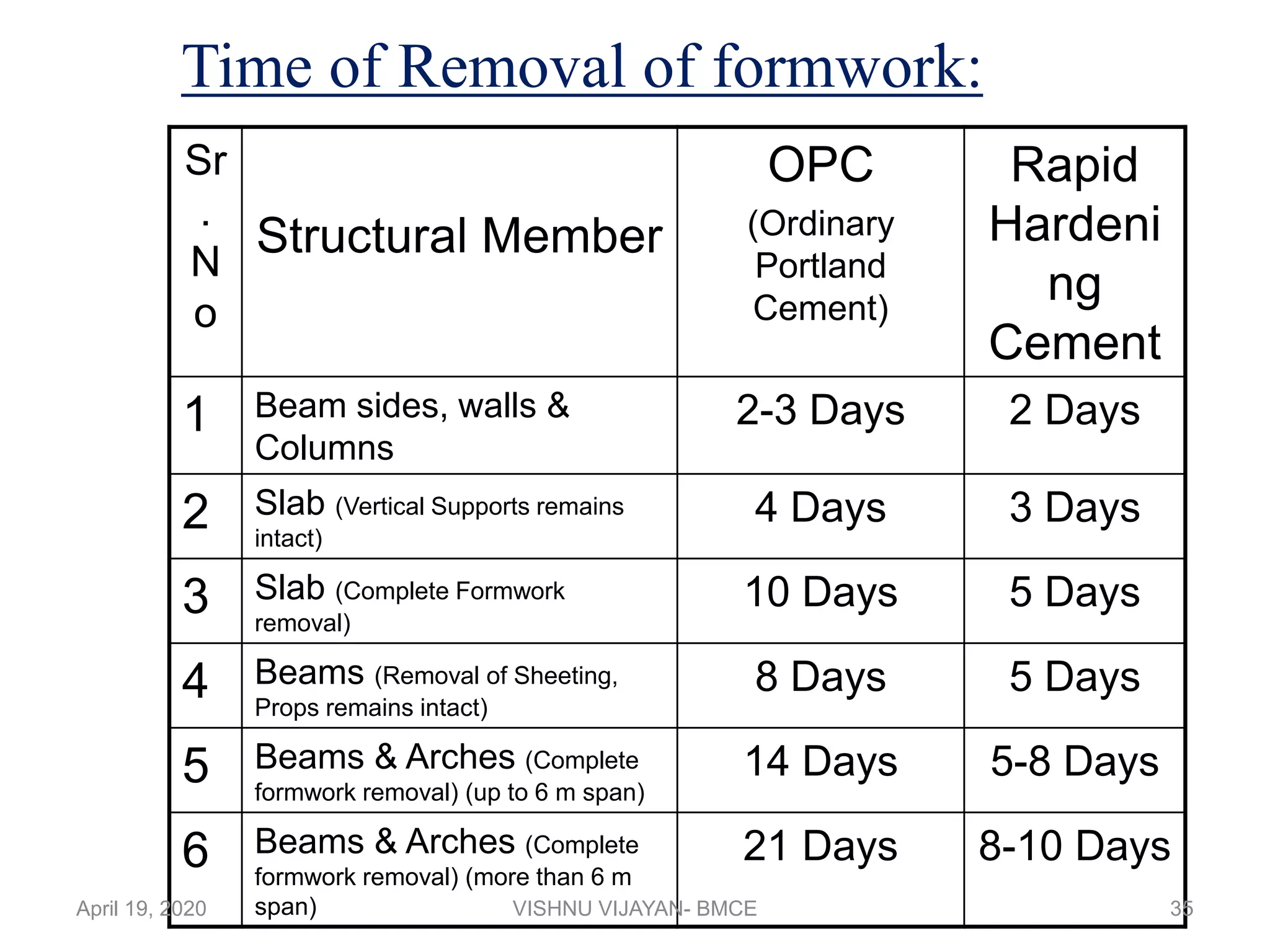

The document discusses the importance of formwork in concrete construction, highlighting its role in supporting fresh concrete and steel, and its significant impact on project costs and construction timelines. It outlines the qualities, uses, and requirements of formwork, as well as detailing the various types utilized for different structural members such as walls, columns, and slabs. Additionally, it covers considerations for design and maintenance, the costs associated with formwork, and methods for removal after concrete setting.