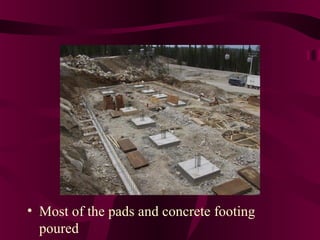

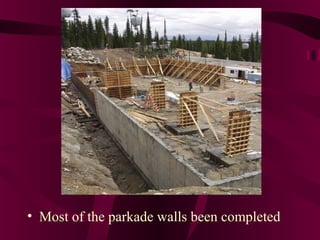

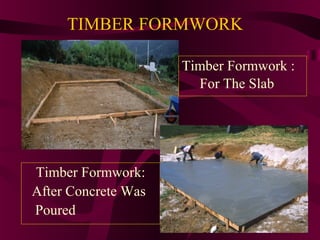

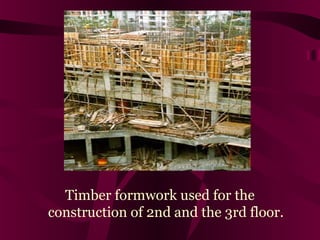

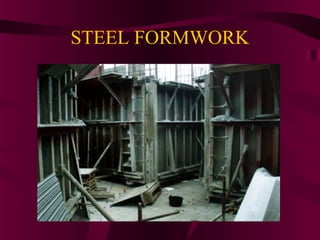

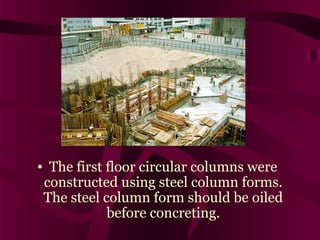

Formwork is a temporary structure used to support wet concrete until it cures and can support itself. There are different types of formwork materials including timber, steel, and glass reinforced plastic. Proper formwork design and construction helps ensure safety, cost-effectiveness and quality of the finished concrete surface. Common causes of formwork failure include inadequate bracing, vibration, unstable soil or improper stripping. Safety precautions like secure fixing and inspections are important to prevent accidents. Permanent formwork is part of the permanent structure and remains in place for the life of the building, offering advantages like reduced construction time and costs.