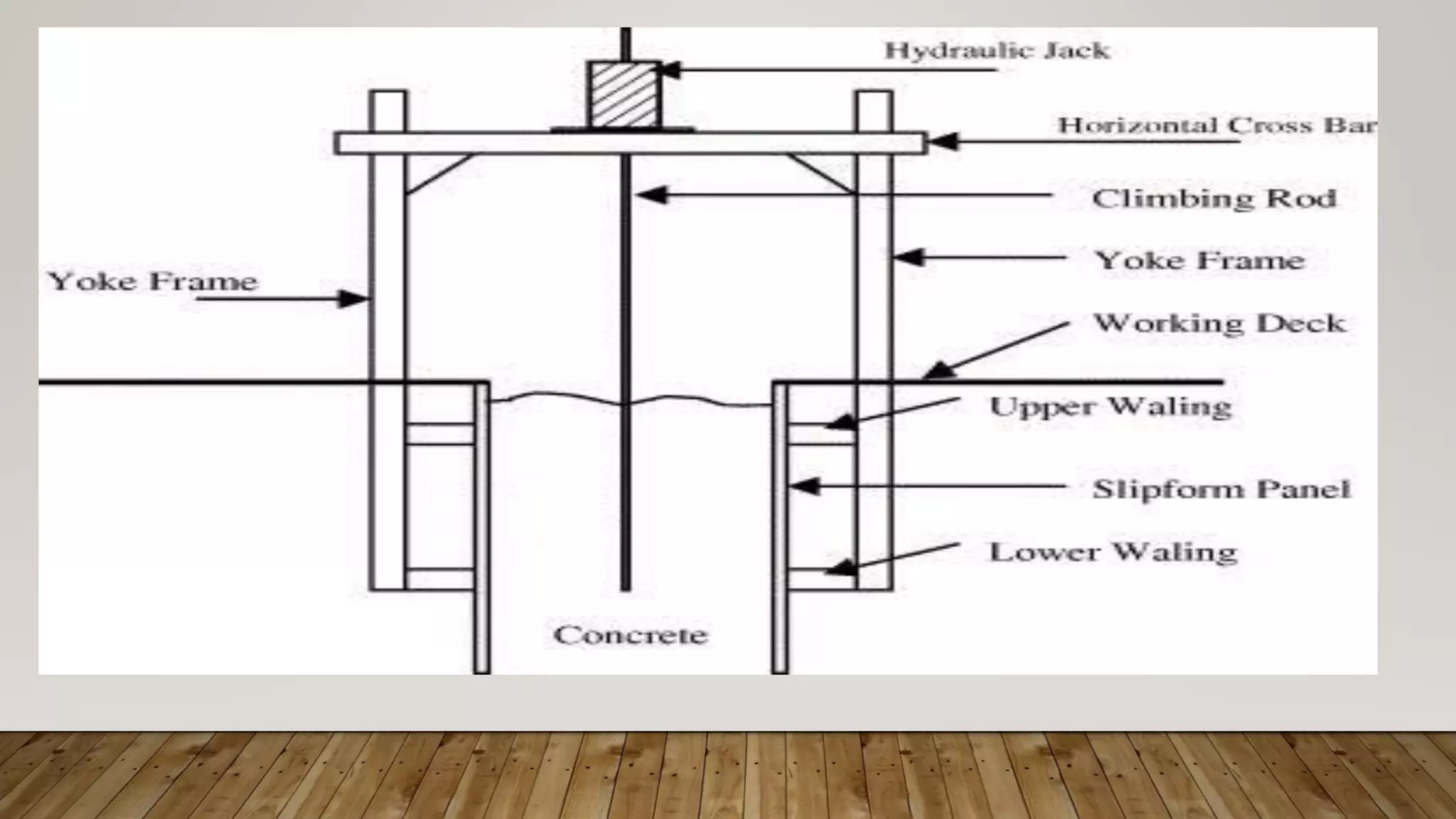

The document discusses slip form construction as an advanced technique for creating continuous, joint-free concrete structures, highlighting its advantages over traditional methods. It outlines the mechanization of the process, which requires fewer skilled laborers, improves construction speed and safety, and reduces costs associated with scaffolding and formwork. It also considers the impact on employment, suggesting that while mechanization may reduce demand for carpenters, it is necessary for handling complex and demanding construction projects efficiently.