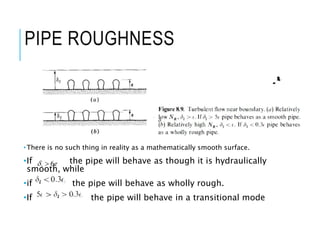

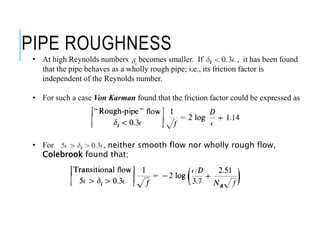

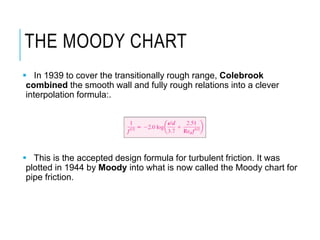

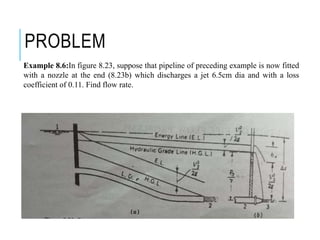

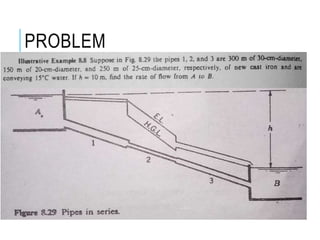

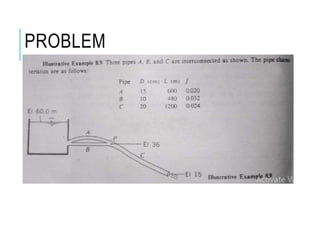

This document summarizes a lecture on pipe roughness and branching pipes. It discusses how pipe roughness affects friction factor and flow. As roughness increases, a pipe will transition from smooth to rough flow. The Moody chart graphs this relationship and is a standard tool for determining friction factor. The document also provides examples of calculating flow rates through pipes using friction factor and discusses how branching pipes affects flow.