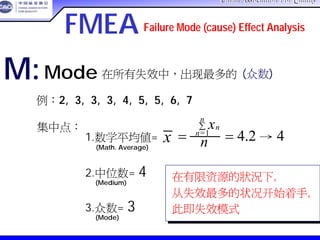

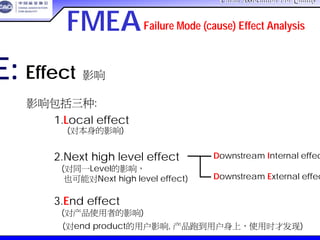

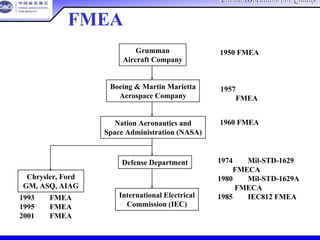

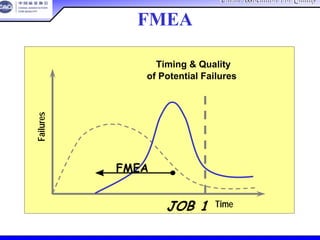

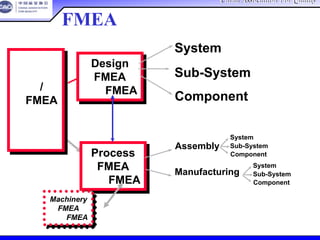

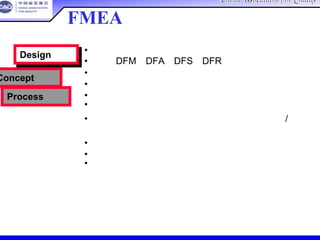

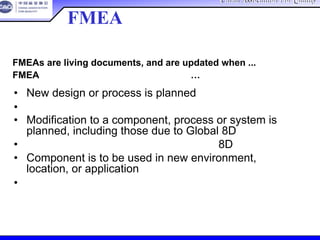

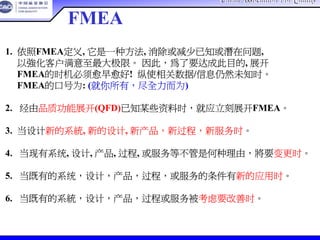

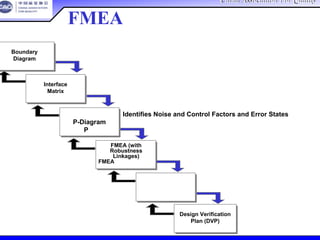

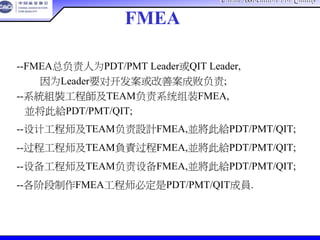

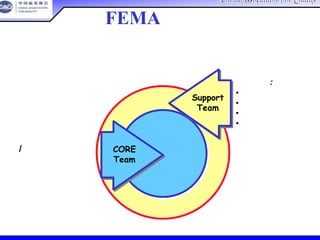

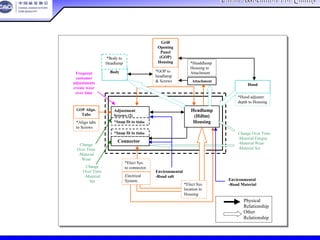

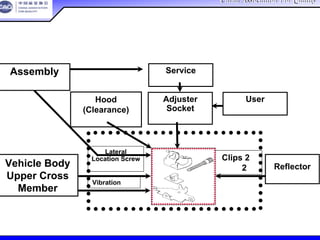

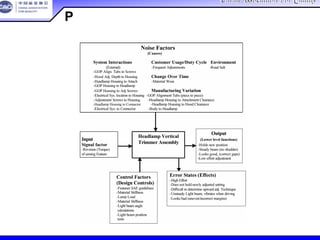

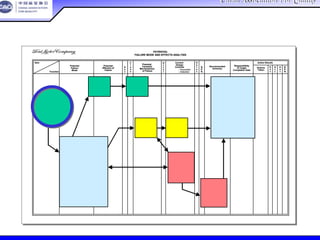

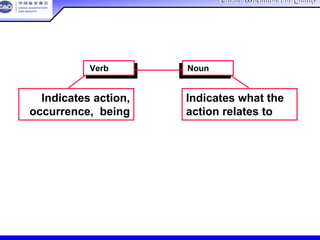

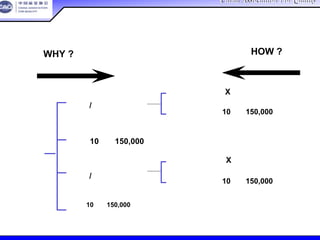

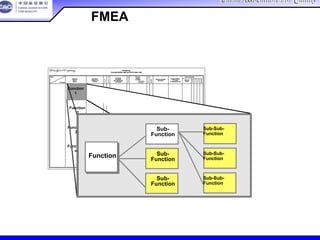

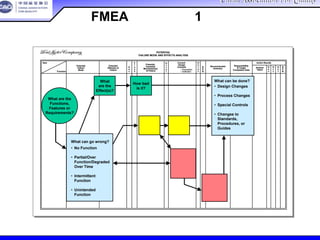

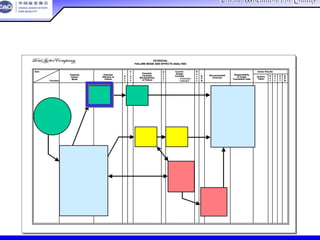

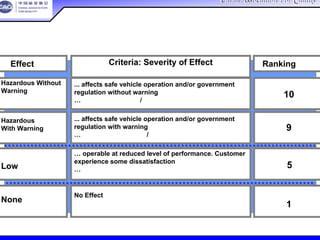

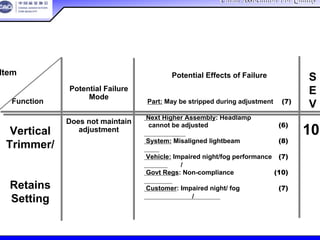

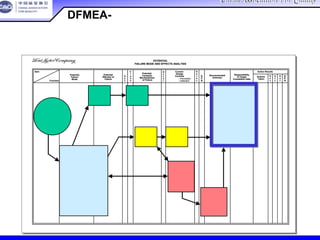

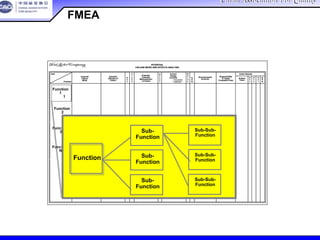

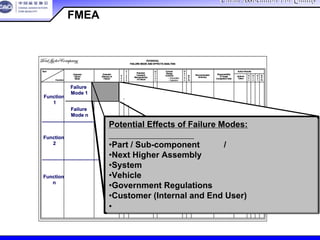

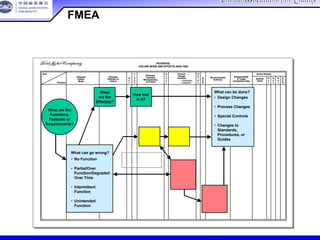

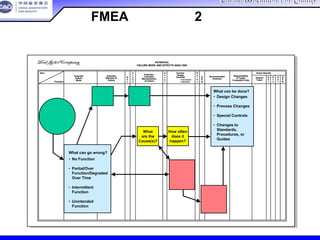

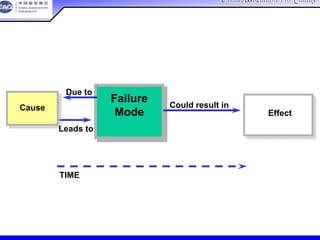

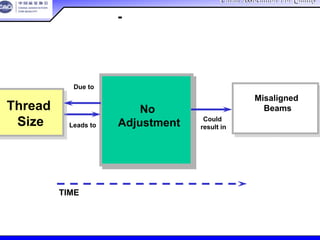

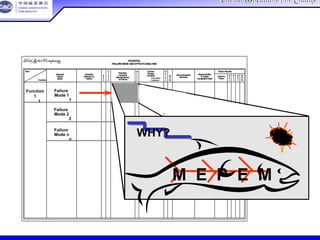

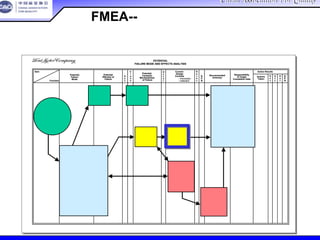

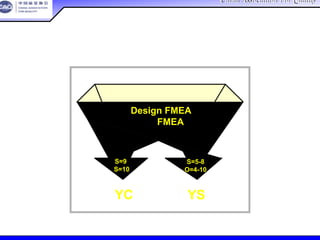

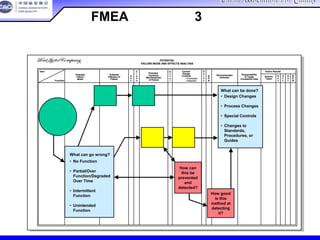

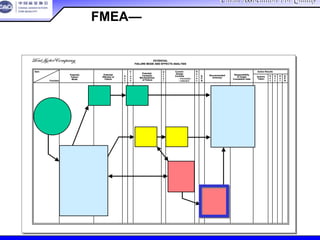

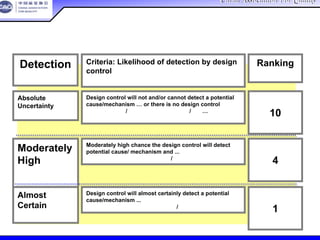

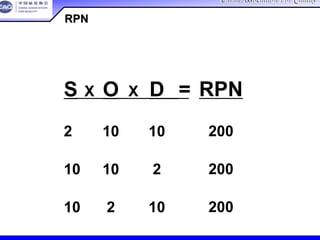

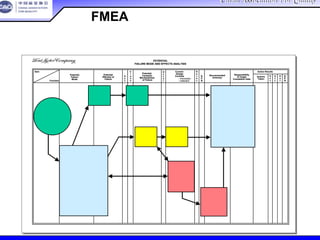

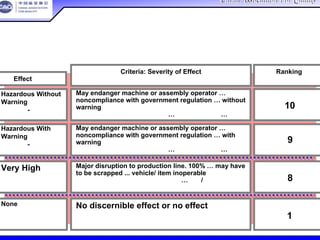

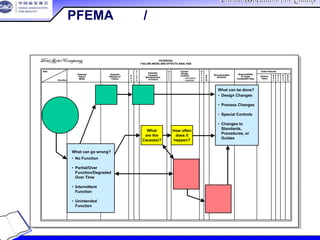

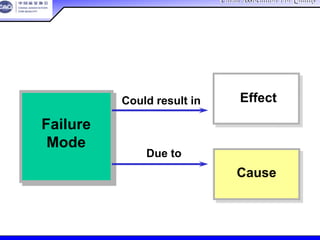

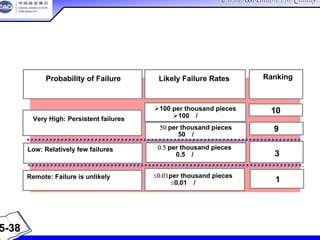

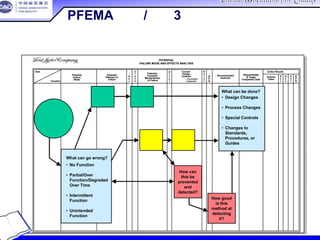

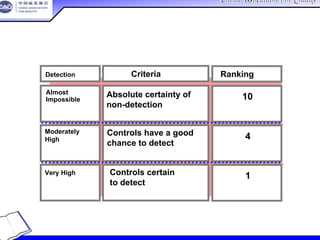

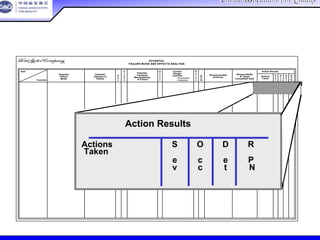

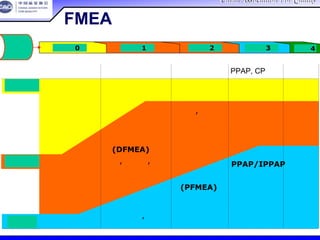

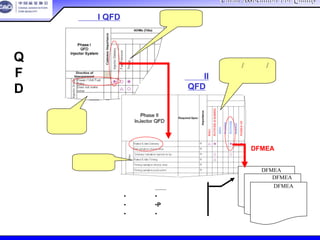

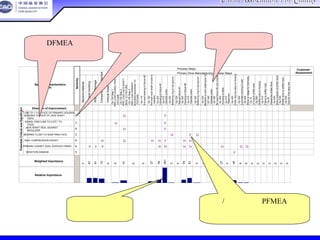

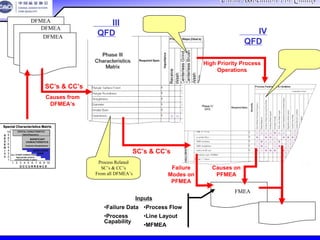

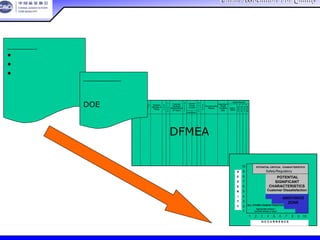

The document discusses an FMEA training presented by Mccain.Koo from June 10-12, 2005. It introduces FMEA definitions, purposes, benefits and types. It discusses when and why FMEAs should be conducted, who is responsible for developing them, and when they should be updated. The training also covers FMEA scope, the design FMEA process, and establishing a design FMEA team.